Developing an environmental management and audit system

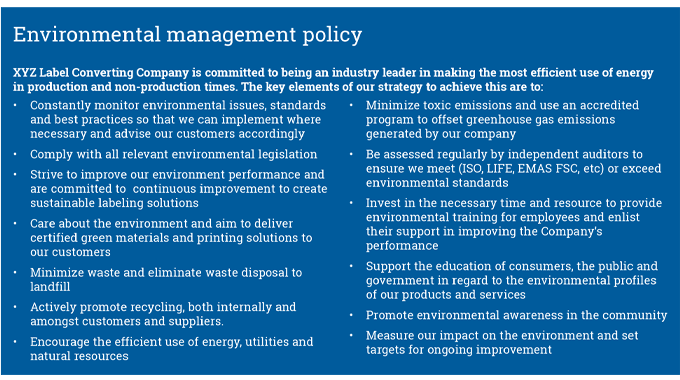

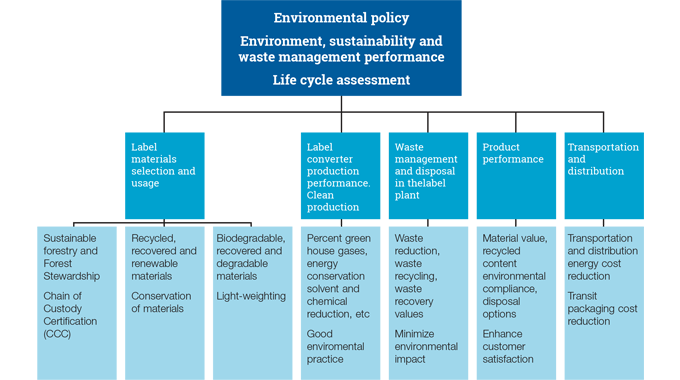

There can be little doubt that label companies that have introduced one (or more) of the environmental management and audit systems, such as ISO 14001, LIFE or EMAS, into their plants have been able to significantly reduce materials (substrates and inks) wastage; have improved their manufacturing efficiency and reduced downtime, water and energy usage; have helped their customers to reduce or lightweight their packaging or labels; created a better partnership with customers in solving joint environmental problems; and found new solutions for, say, label matrix waste disposal and/or reuse in fuel efficient energy (pellets) or building materials.

In short, meeting environmental guidelines and standards has proved to be a good, cost-effective business decision. Some have even been able to provide well-documented and substantial cost savings . even more of a reason to invest in such schemes.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.