Xaar fast-tracks inkjet development

The new streamlined approach reduces development time and costs for manufacturers.

Xaar has enhanced its fluid development and optimization process to help manufacturers and OEMs fast-track inkjet system development, reduce costs and drive innovation.

The new flexible and scalable process gives customers a faster, more efficient route to market, whether they choose from Xaar's wide range of approved fluids or develop their own with dedicated waveform support. Leveraging Xaar's printhead technology and expertise in handling inkjet fluids, the process minimizes early-stage capital investment and enables early fluid verification.

By reducing risk and accelerating development cycles, customers can deliver high-performance applications more efficiently. In addition, Xaar's unique capability to jet challenging fluids, including those with high viscosity, particle loading or large particle sizes, helps speed development of inkjet's use in innovative applications.

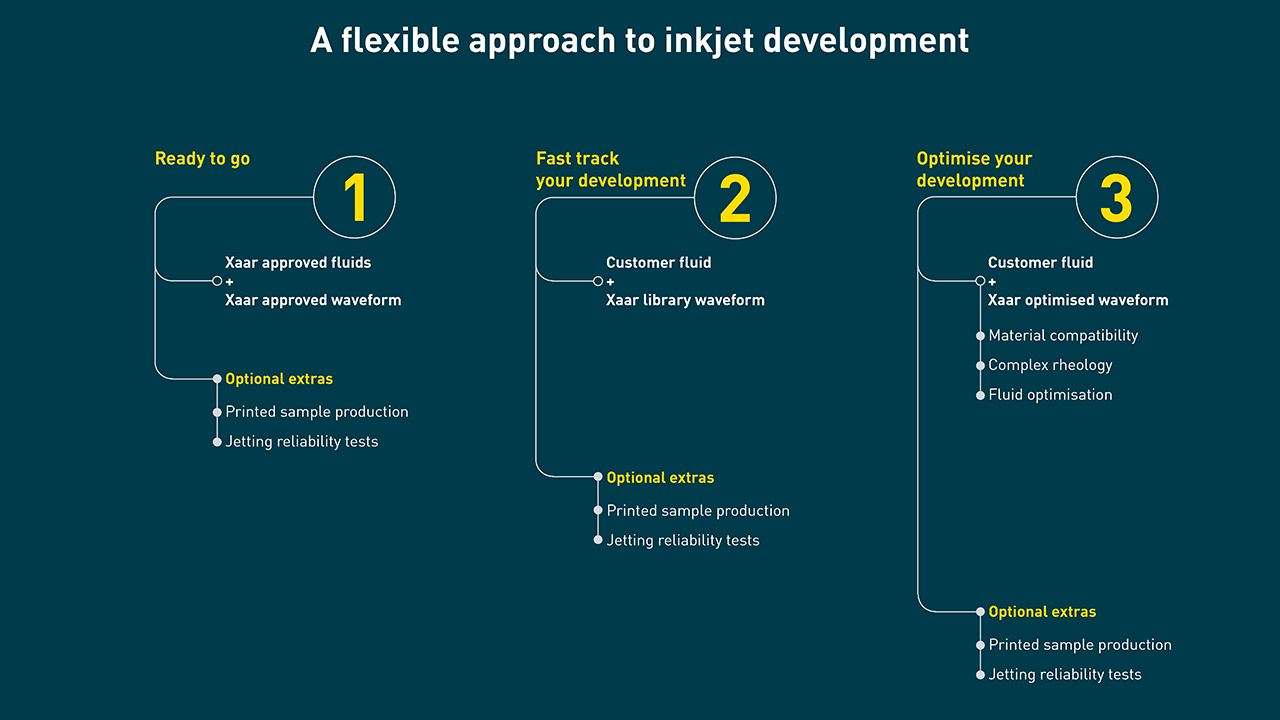

The new process supports three key pathways for development. The quickest route is to choose from a portfolio of pre-approved fluids, each supplied with tailored waveforms and confirmed compatibility with Xaar printheads. These fluids have already been optimized for a range of applications, allowing for rapid system integration.

For customers using their own fluids, Xaar offers the ability to fast-track development by selecting a matched waveform from its extensive library, based on detailed rheology analysis. This approach enables immediate progress while a fully optimized waveform is developed in parallel, ensuring print performance can be further enhanced without delaying R&D momentum.

When customers require a bespoke waveform, Xaar provides a comprehensive service that includes materials compatibility testing, rheology measurements, jetting diagnostics and bespoke waveform development to ensure the highest print quality.

Optional development kits and printed samples can be provided to demonstrate achievable results with all three pathways, while Xaar's ongoing consultancy and support ensure reliability and repeatability throughout the process.

'We understand how crucial speed, performance and cost are when developing new inkjet systems. Our new fluid development and optimization process is designed to give customers the flexibility and tools they need to innovate faster and reduce risk, whilst remaining in control,' noted Graham Tweedale, COO at Xaar. 'Whether validating a concept or scaling a disruptive application, we're here to help our customers work faster and smarter, with the full backing of our trusted technology and experience.'

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.