Adding value to California’s wine industry

Danielle Jerschefske reports on the flexible printing technology and strong partnerships with clients and designers that are allowing Tapp Technologies’ to bring value to California’s wineries

Based in Napa, California, Tapp Technologies entered the wine label market in the early 1990s, investing in Sanjo waterless offset technology. Offset provides a thick ink coating and high quality still in demand by the wine world today.

The wine industry differs from other sectors of the label market because of the unique process of turning grapes into wine. What’s inside the bottle holds a piece of the winemaker’s heart and the label must express the essence of its contents.

Travis Pollard, digital business manager at Tapp, explains, ‘People are extremely passionate about wine, which is why label design and print quality are so important in this market.’ On-time delivery is critical since bottling, a significant cost in the entire process, cannot be completed until the labels are applied to the bottles; and accuracy in bottling time can affect the outcome of the product, so there is a lot at stake.’

Tapp’s diverse portfolio of technology includes flexography and liquid toner digital, which supports a varied customer base and gives the converter a competitive edge. Bill Knopka, senior vice president, explains, ‘It’s really about flexibility, and being able to tailor our solution to fit customers’ projects. With a variety of printing platforms we can customize any solution for them.’

Pollard and his team work closely with clients throughout the decision-making process. ‘Wineries have an acute variety of needs and typically request highly complex embellishments, requiring the most advanced printing technique available. At Tapp we take a close look at which technology should be used in order to service a customer’s needs most appropriately. Run length, label design, and total budget are just some of the things taken into account before an order is scheduled and printed.’

Small orders reap big rewards

Introduced in the early 2000s, HP Indigo’s ws4050 digital technology allowed Tapp to break into the under-served boutique wine industry, strengthening the business. Knopka explains, ‘With the investment in digital printing we were the first to introduce a number of solutions to the California wine market. Digital technology allows us to supply wineries with small orders of premium quality labels yet remain cost effective.’

The number of boutique wineries has increased around the world over the last 15 years. The niche market needs labels that reflect the quality of the wines produced. Pollard says, ‘we focus on small lots of high-end wine.’

Crushpad winery

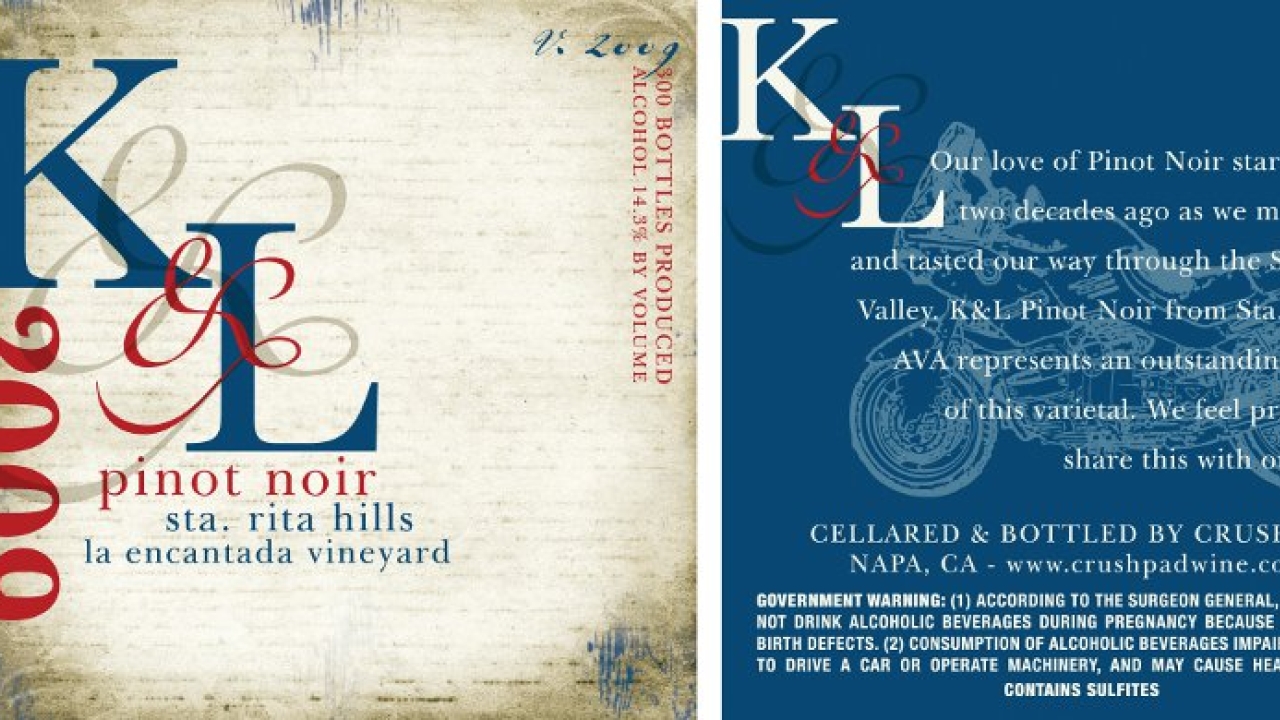

Crushpad allows anyone to make a signature wine. From grape selection and harvest, crushing and aging through to label design, selection and joyful consumption, the winery assists customers in tailoring their own wine.

The winery’s in-house packaging team supports clients in creating exclusive labels which expresses their individual stories. The three designers, Jenny Doll, Hayley Partridge and Kelly Fooy, have a weekly label quota to meet and each turn out 10–15 labels a day.

The Crushpad packaging team takes ultimate responsibility for the accuracy of each design and the label’s proof. Once a designer signs off on the work internally, the file is loaded to a website and automatically put in the scheduling queue at Tapp.

Design

Assisting clients in selecting a label is a very intimate process. Creative director at Crushpad, Jenny Doll says, ‘Some clients are very clear about what their needs and wants are. They’ll have photos, or an image, past labels – which facilitates the decision. On the other hand, some have no idea what they’re looking for; they need a name, a concept, a design. This requires more consultation and guidance by the staff probing about their lives.

‘It is a very personal way of crafting composition. We bring our design and interpretation skills to the table, listening to what is wanted and what the story is, to build a meaningful label. When we create a design the client must be able to look at the label and see their story unfold.’

Tapp keeps designers up-to-speed with the latest technology developments in print technology and educates them on printability. Tapp has developed cross-industry relationships up and down the valley. Keeping in regular communication with the design community is integral to the business. Knopka says, ‘At the core we are a manufacturer, but if you ask our customers then we are a service provider.’

Partners

‘Our partnership is phenomenal,’ says Jenny Doll referring to Crushpad’s relationship with Tapp. Crushpad offers a selection of regular die shapes and papers for customers to choose from. It prints around 1,000 different labels each year, running about 30-60 different labels every other week. ‘Prior to working with Tapp it was a full time job to monitor, track and organize label orders and press checks.’

More automation support from the converter has freed up Crushpad to expand by allowing its designers and winemakers to focus more on customers and less on the technical aspects of producing a timely, well-printed label.

Crafting a brand

Crushpad has what it calls a ’commerce division’ where it consults and supports the incubation of wine brands. Doll says, ‘the process is intense and requires us to really become acquainted with our customers. Like the signature wines, often you’ll find personal bids within the label, but it is a very different story because with the signature wine, the label is not meant to attract a buyer. Here, the package must provide a story that people will, quite literally, buy in to.’

The label is key to the overall experience of Crushpad’s clientele and any wine consumer. Doll says, ‘They open and pour, talk about the process, new oak versus old; it is a full experience. That label has to bring back memories to reflect who they are as people. The label is the final footprint and a constant reminder of their experience.’

Expansion

With the growth of Tapp’s digital business, the company moved to a new building at the close of 2010. The new plant has double the space, allowing more efficient label production and giving the converter room for further growth and capital investment.

Knopka believes the company will continue expanding with digital technology, and is continually investigating and testing new substrates for the Indigo press. An upgrade to the WS6000 is on the horizon, but more R&D must be completed on a range of stocks important to the company’s target market before a decision is made.

‘Other growth will come organically from our current customer base and we will look into establishing a greater geographic reach,’ continues Knopka. The converter is focusing on the California wine market, but looking to translate its success to the rest of North America, where there are currently more than 6,000 wineries. ‘The dynamics that we see in those markets are at the same point that the California wine market was previous to the inclusion of digital to our platform.’

Knopka says that overall the effects of the economic recession have been minimal. He attributes this stability to Tapp’s customers who produce high value wine, where unit sales actually rose in recent years. The wine market has also seen a trend for greater use of tactile embellishments and other supplier-led innovations.

With a new location, passionate staff and creative ideas, Tapp will continue to match the packaging objectives of both large and small wine brands, focusing on digital and providing unique solutions with unrivaled service.

Click here for more stories about Tapp Technologies on L&L.com.

This article was published in L&L issue 1, 2011

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.