Flxon to market Brookfield’s viscosity control systems

Charlotte, North Carolina-based Flxon has partnered with Brookfield Engineering Laboratories to market the latter’s line of viscosity control systems to the flexo and rotogravure printing industries.

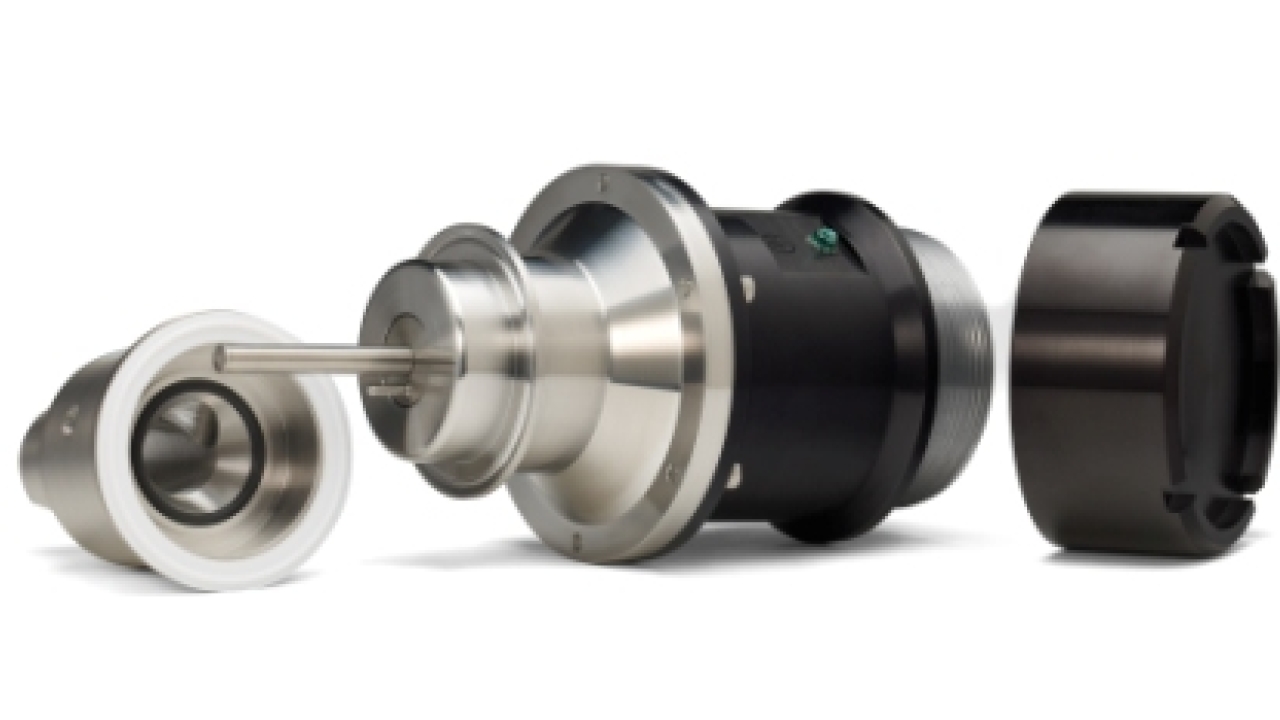

For more than 75 years, Brookfield Engineering has designed, engineered and manufactured precision viscosity measuring technology. Earlier this year, the company launched the newest version of its AST 100 sensor. Flxon’s marketing manager, Mark Johnson, says: ‘It’s even smaller at eight and a half inches in length, so it can easily be placed in-line in any application.

‘The distinguishing features of the new AST 100 sensor’s advanced micro-harmonic sensing technology are that it has no moving parts, is easy to flush in-line, is unaffected by vibration, and can be mounted vertically or horizontally. It even senses temperature. Feedback from the more than 1,000 sensors in use is extremely positive. Customers report it is more user-friendly and reliable then their old systems – even on tough coating and laminating applications.’

The AST 100 sensor is the heart of Brookfield’s control system, which is available in the single unit ‘Uno’ and the multi-station ‘Multiplo’ for controlling up to 12 stations. All systems are programmable to control viscosity to within 0.5 sec on a number 2 Zhan cup. Trending and reporting on viscosity can be in cup or any other measurement. Temperature can be reported in F or C.

According to Johnson, a number of major press manufacturers have already moved to the AST 100 sensor as part of their standard new press offering.

Click here for more stories about Flxon on L&L.com.

Click here for more stories about Brookfield Engineering on L&L.com.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.