Label printers boost profits with capsules

Label suppliers worldwide are discovering untapped revenue by expanding into bottle capsule manufacturing.

The shift represents a strategic response to evolving market demands, as premium bottled products increasingly require both labels and capsules as part of cohesive packaging design. From wine and spirits to olive oil and health supplements, bottle capsules have evolved beyond simple sealing functions to become essential branding elements.

Market demand drives expansion

Brand owners today expect unified design between bottle labels and capsules, faster lead times and streamlined supplier relationships. This creates natural opportunities for label printers to capture additional business from existing clients while attracting new customers seeking comprehensive packaging services.

Label suppliers already understand their customers' packaging requirements and production timelines. By offering both components, printers can provide complete packaging programs that eliminate the need for clients to coordinate with multiple suppliers.

Revenue opportunities multiply

The expansion into capsule production opens doors to emerging markets including health products, cosmetics and premium gift packaging. Label printers report that capsule capabilities help them win orders that would otherwise go to competitors offering broader service portfolios.

In-house capsule production enables simultaneous manufacturing of labels and capsules, reducing delivery times and improving integration with client packaging schedules. The approach also allows printers to serve customers seeking only capsule production, expanding their addressable market.

Technology enables growth

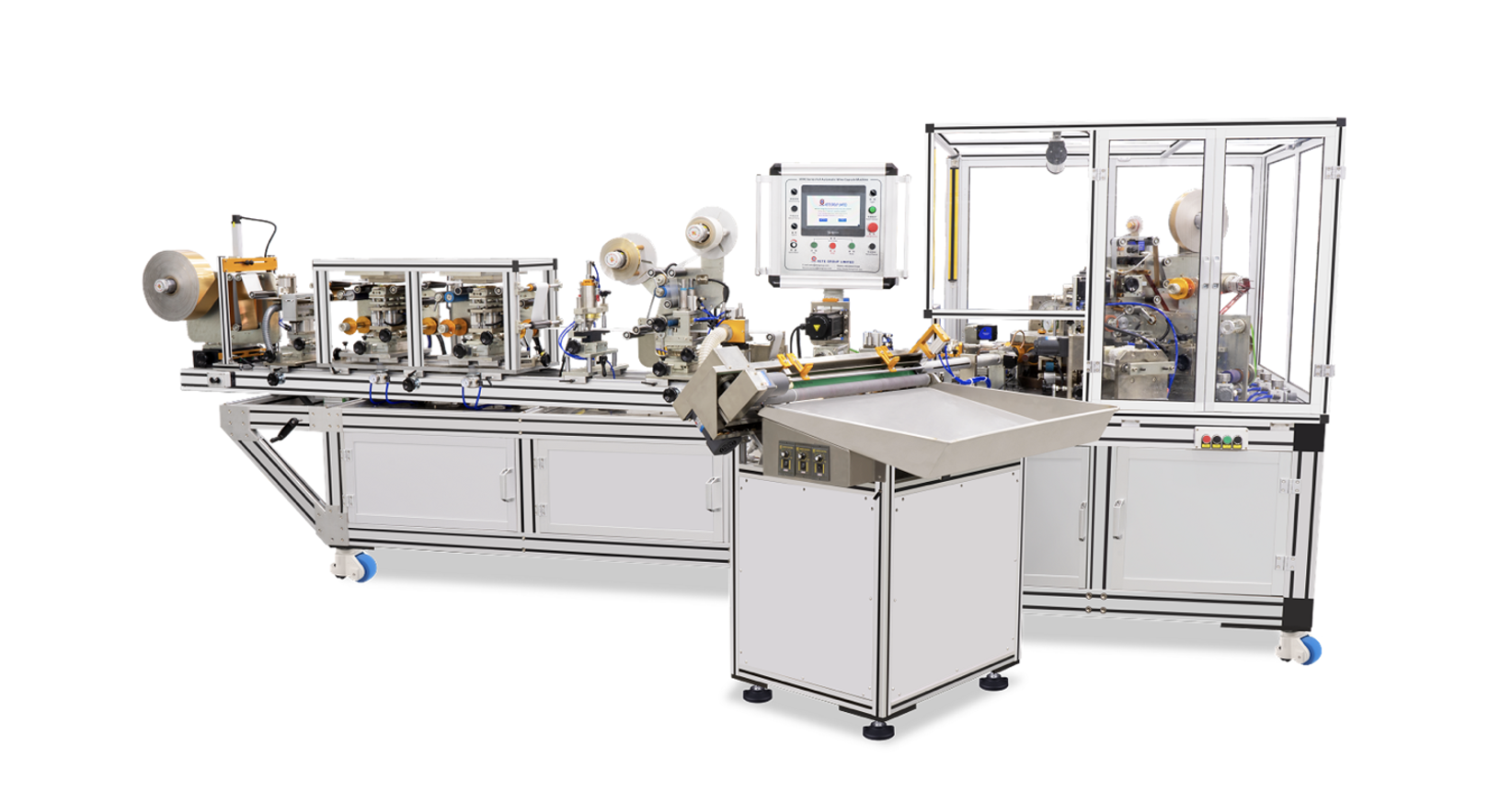

Modern capsule making equipment supports multiple materials and automated processes, including forming, perforation and tear-off tape insertion. Advanced machines offer embossing, hot stamping and raised printing capabilities in fully automated production lines.

Kete has helped label printing companies across Italy, Spain, Portugal, Brazil, Georgia and Russia establish capsule production capabilities. The company's equipment supports various materials and includes automatic forming, perforation and finishing processes.

Integration benefits emerge

The combination of label and capsule production allows printers to ensure visual consistency across packaging elements while reducing handover costs between suppliers. This integrated approach can increase profit margins and strengthen customer loyalty through enhanced service offerings.

Companies adopting capsule production report that the investment generates quick returns through new revenue streams from existing customer relationships. The technology also positions printers to serve premium market segments where packaging aesthetics play crucial roles in brand differentiation.

Kete will demonstrate its wine bottle capsule making machine at Labelexpo Europe 2025, Hall 3, Booth 3A62. The company offers free samples and customized demonstrations on-site. Learn more: https://www.ketegroup.com/lp/labelexpo-europe-wine-capsule-machine/

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.