Trim Waste Management reopens cutter shop

The company offers 40 percent savings on cutter maintenance for label converters.

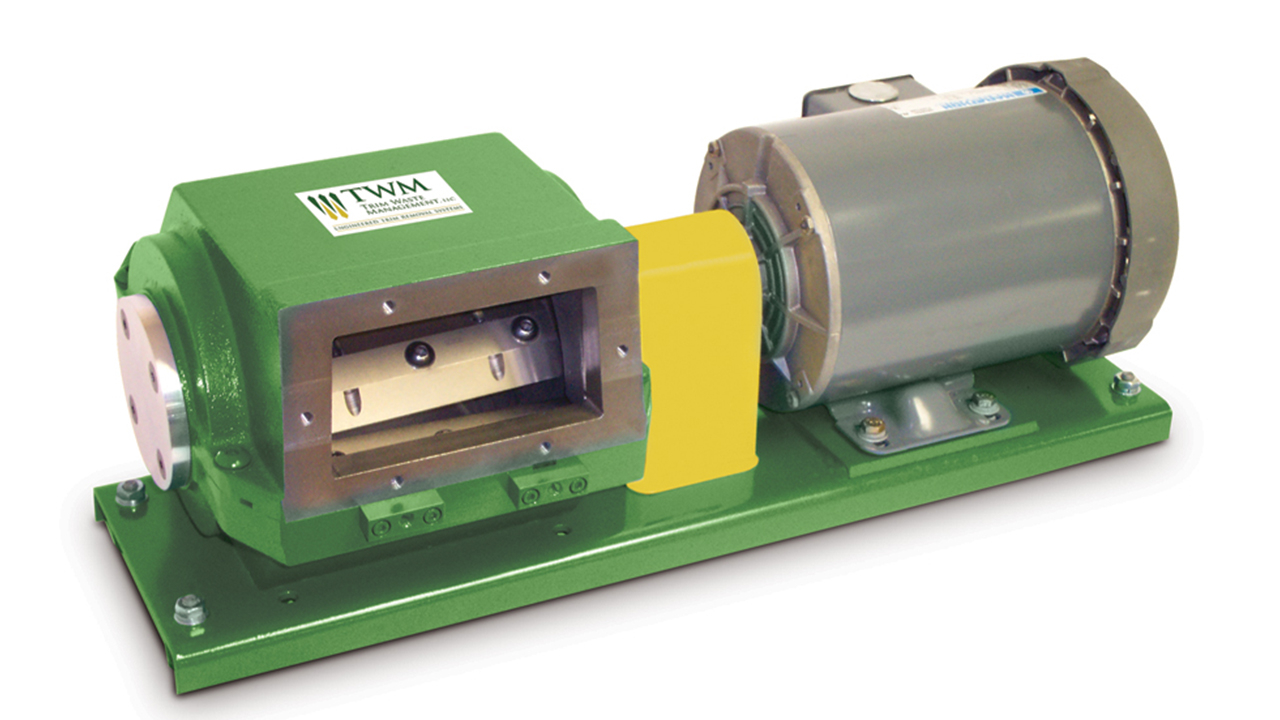

Trim Waste Management has reopened its cutter shop, expanding its capabilities to include refurbishing and sharpening services for a wide range of cutting systems used to precisely cut and process trim and matrix waste in label and flexible packaging production.

The company announced the expansion, providing converters with a cost-effective way to maintain and extend the life of existing cutters while preserving the precision and durability their operations demand. The company's newly relaunched service center refurbishes cutters from most major brands, including Precision Air Convey, Kongskilde and BlowAPCO, with average turnaround times of one to two weeks and cost savings of approximately 40 percent or more compared with competing services.

'Our customers are under more pressure than ever to manage costs and keep production lines running efficiently,' stated Kevin McCloskey, CEO of Trim Waste Management. 'Reopening our cutter shop allows us to deliver that value, offering high-quality refurbishing services at roughly 40 percent less than other companies that offer similar programs. With decades of experience designing and servicing pneumatic cutter trim removal systems, we're proud to help converters extend the life of their equipment and keep their operations running smoothly.'

Each refurbished cutter undergoes TWM's meticulous seven-step maintenance procedure, which includes complete disassembly and inspection, bearing checks, surface and spin-grinding, knife clearance reset to factory specifications and final test cuts to verify proper setup and function. The result is clean, accurate operation and renewed performance across all supported systems.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.