Swiss converter targets Far East growth with Bobst Accucheck

- Fratelli Roda first to install Bobst Accucheck in Switzerland

- Promoting new kit to both new and existing customers

Fratelli Roda has become the first Swiss company to install a Bobst Accucheck unit, which delivers the capability to in-line quality check all of its folding carton production.

The company’s management said they expect the unit to reinforce its position as a supplier that pays constant attention to quality and will help it acquire new customers, particularly in the Far East.

Fratelli Roda is also confident that the technology will allow the company to acquire new customers in the pharmaceutical and cosmetic industries.

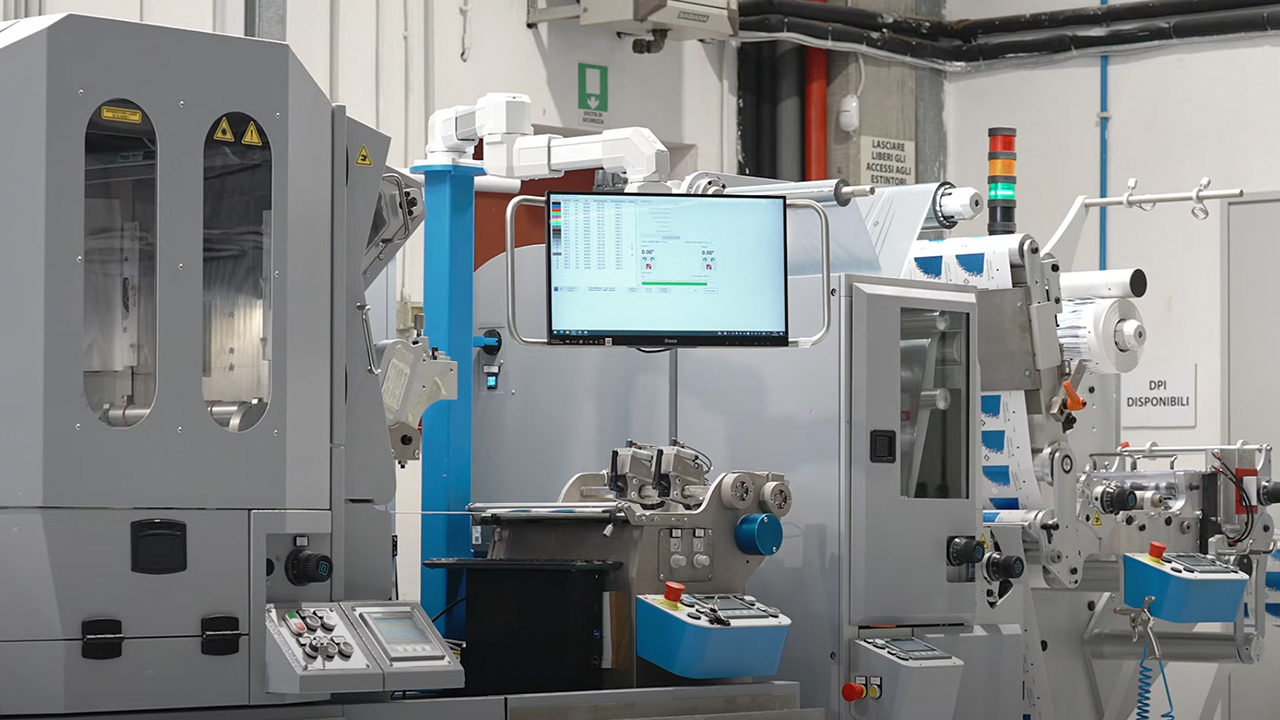

Located in Taverne, Switzerland, Fratelli Roda produces paperboard packaging, and commercial print products, with 60 percent of the company’s production being for the pharmaceutical market. The company runs three Bobst folder gluers, including a new Expertfold 80 A2, which has the Accucheck unit fitted in-line and also features a Handypack GT packer.

Fratelli Roda also runs a number of Bobst die-cutting units on its shop floor.

Franco Roda, general director of Fratelli Roda, said: ‘As a 70-year-old company, which stands out for investing in innovative technology, it was natural for us to look at further improving the quality of our products.

‘Our customers are on a continuous quest for perfection and we chose the Accucheck unit because it can check 100 percent of our production.’

He added: ‘In-line quality control saves our customers’ time and guarantees them that 100 percent of the production we supply them has been checked. There is a market for this in pharmaceuticals where, in Japan for example, it is extremely important.’

Placed in-line with a Bobst Expertfold or Masterfold folder gluer, Accucheck units check each carton for issues such as printing defects, oil or water marks, ink splashes, carton damage or scratches, bad cut quality, or color variation, and prevents any carton exhibiting such defects from reaching the packing line.

Franco Roda said: ‘Production is 100 percent checked and not just partially or statistically controlled.’

The company is now actively promoting its Accucheck installation to both existing and potential customers. ‘We want them to hear that we have Accucheck in-line quality control,’ Roda said, ‘to know the features of this innovative technology, and to understand the substantial advantages Accucheck will bring them.’

Read more on Bobst here

Read more about finishing and converting technology here

Read more about inspection equipment here

Read more news from across Europe here

Read more news from the Asia-Pacific region here

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.