Mizsepack invests in GM LC350 die-cutter at Labelexpo

With the LC350, Mizsepack can finish labels digitally, switch seamlessly between jobs and deliver to customers more quickly.

Mizsepack, a Hungarian supplier of packaging products, has invested in the Grafisk Maskinfabrik (GM) LC350 laser die-cutter to reduce delivery times, handle frequent job changes more efficiently and eliminate the costs and delays of traditional die plates.

Conventional converting meant long setups, multiple shifts and waiting days for plates, challenges that made it difficult to keep pace with customer demand.

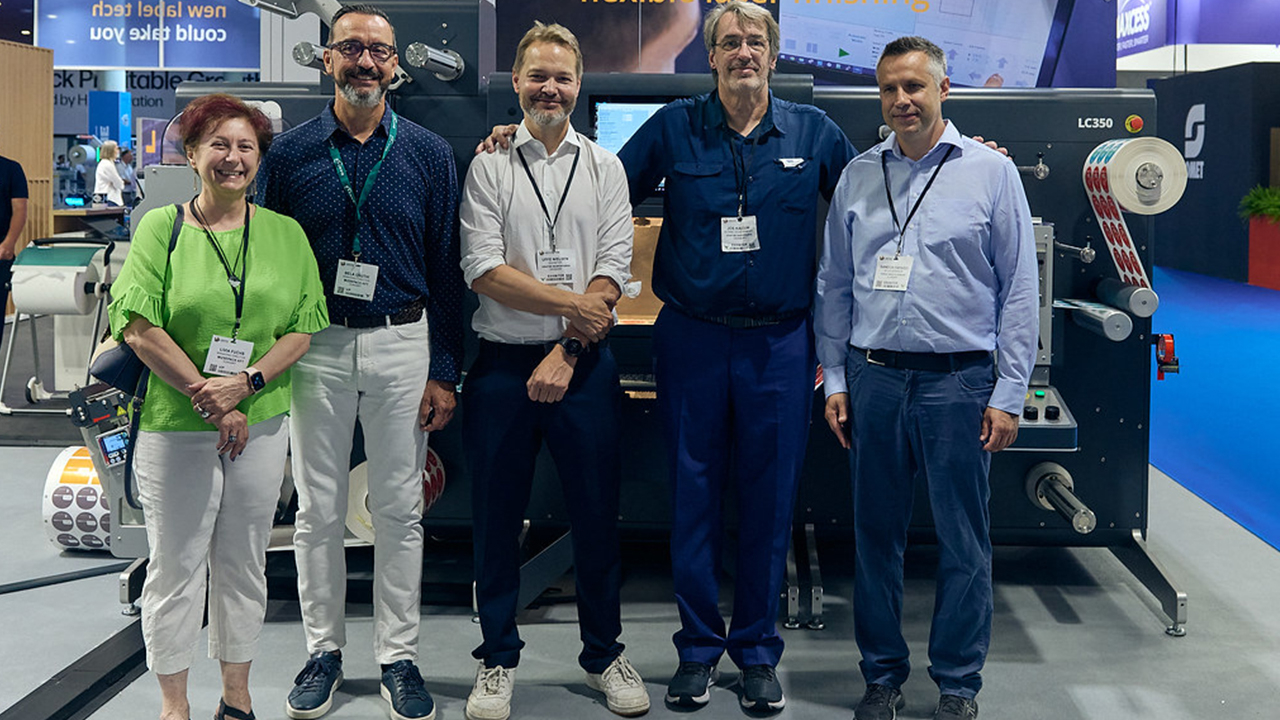

Lívia Fuchs and Béla Csuthi, owners of Mizsepack, said: 'Our vision was clear: to complete label printing and finishing within the same shift, operated by the same person running the AccurioLabel 400.'

With the LC350 laser die-cutter, the company can now finish labels digitally without plates, switch seamlessly between jobs and sizes, and deliver to customers more quickly. This technology offers the company greater flexibility, independence and efficiency, while maintaining quality.

'It’s inspiring to see how Mizsepack is embracing digital finishing to transform their business. The LC350 gives them the speed, flexibility and independence they need to stay ahead in today’s fast-moving label market. We’re proud to support their journey,' said Jos Kabouw, global sales manager, GM.

The GM LC350 was sold by Sándor Faragó, production printing sales manager, through Konica Minolta Business Solutions Hungary.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.