Elep taps new market with Truepress Jet L350 SAI LM

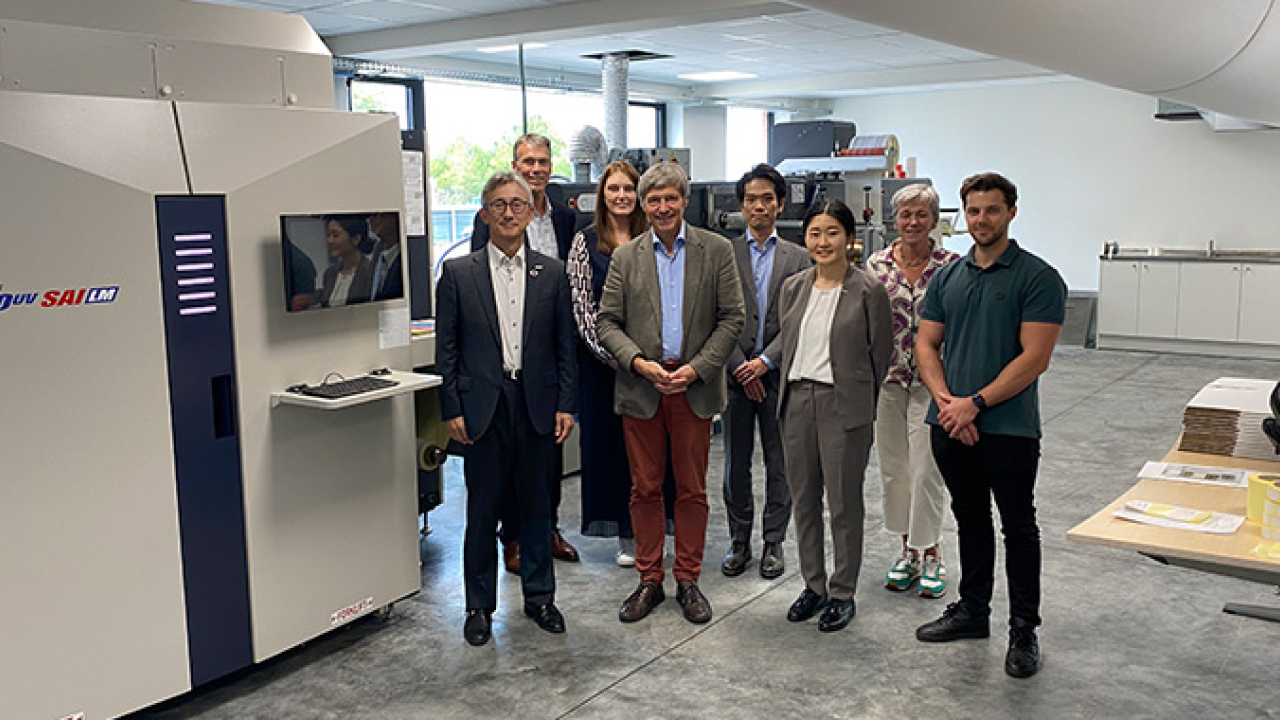

To break into a new market, Belgium-based Elep has invested in Screen Truepress Jet L350 SAI LM, a digital-printing label press that meets the latest standards for food packaging.

Elep has a rich history as an envelope manufacturer, dating back to 1963. Today, with its 65 employees, Elep is the last industrial envelope manufacturer in Belgium.

‘To ensure our long-term continuity, we wanted to diversify our activities,’ said Yves Peiffer, Elep’s CEO. ‘We opted for the production of self-adhesive labels on rolls – it’s a different segment from envelopes, but one where we can apply our know-how built up over decades.’

The company chose the Truepress Jet L350 SAI LM from the Japanese supplier Screen.

‘Screen Europe came out as the best option in terms of combined quality, service and price,’ added Peiffer. ‘We felt it was important to bring in the very latest technology. Our new printer is the very first installation of the SAI LM outside Japan. The 'SAI' in the printer's name refers to the bright, high-quality colors it can print. The colors are very stable and scratch-resistant, which is appreciated by label buyers from all industries. 'LM' stands for the 'low migration' of ink particles, and the LM ink complies with key regulations in Europe for food packaging.’

After-sales support was another important factor in choosing the printer. Screen Europe technicians trained Elep’s staff in Lommel over the summer and are on hand at any time with technical advice. Screen's European headquarters is based in Amstelveen, just a 90-minute drive from Elep’s facilities.

With its new printing press, Elep targets small to medium print runs, including those for food producers. Given its digital technology, Elep can deliver print runs as small as 100 labels but also rolls with several hundred thousand labels.

The printer offers printing speeds of up to 60 m/min and can reprint personalized labels on demand, allowing customers to keep smaller stocks of labels. Given its longstanding commitment to sustainability, reducing paper or ink losses and working without printing plates are important to Elep.

The company has also appointed Nadine Vanderwaeren, an experienced business development manager for its new label division with extensive expertise in materials and knowledge of the label market.

‘Digital printing is becoming increasingly important as customers demand more and more flexibility,’ commented Vanderwaeren. ‘Elep wants to be a true partner for its new label customers and recommend the best solution in terms of safety, sustainability and efficiency.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.