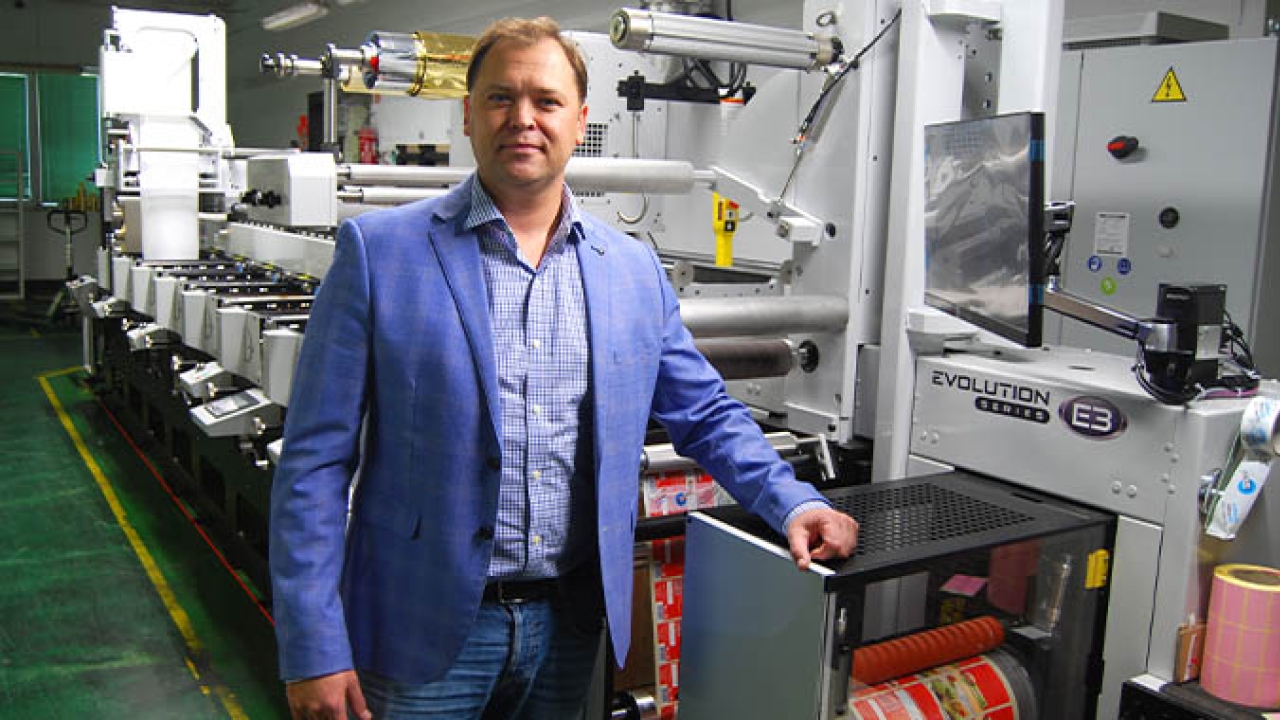

Fano installs third Mark Andy flexo press

Warsaw-based label converter Fano has installed Mark Andy Evolution Series E3 13-in flexo press. The press, equipped with eight printing units, cold foiling, die-cutter and UV dryer, will be used by Fano for printing highly processed self-adhesive labels.

With the new investment, the converter will use its other two Mark Andy Performance Series P5 presses to focus on manufacturing sachet laminates and shrink sleeves. Fano can now manufacture them faster and offer a shorter delivery time.

Family-owned business established by Janusz Jasinowicz in 1986, the company is managed by his son Boleslaw Jasinowisz. It started from diversified production in sheet-fed offset technology.

‘This fact had a direct impact on the name of our company, which consists of the first letters of different products we manufactured in the initial period,’ Boleslaw Jasinowisz, vice president of Fano, said.

‘After buying the first flexo press, we introduced labels to our offer, starting a completely new era for our company. This kind of assortment, with focus on self-adhesive stock, has dominated our production for many years. We have been constantly expanding and modernizing our equipment set, for example, with Mark Andy presses, and offering new types of assortment, including highly processed, sublime products printed in HD flexo technology.’

Currently, Fano’s printing division is based on three Mark Andy presses. In 2013 the company invested in 17-in Performance Series P5, equipped with 10 printing units, cold foiler, laminating unit, screen printing unit, QCDC die-cutter and corona station.

Five years later, Mark Andy delivered the second P5 press with 8 printing units, die-cutter and corona unit. Both presses are equipped with chilled cylinders, auto- and preregister, UV dryer and inline inspection systems.

‘Both purchases were result of changes in ratio of products manufactured by our company. The diversification of our offer was inevitable due to changes in the self-adhesive label market and decreasing profitability in this area. P5 presses enabled us to produce highly processed self-adhesive stock as well as introducing completely new products to our offer including sachet laminates and shrink sleeves,’ Boleslaw Jasinowicz added.

Fano’s new Mark Andy Evolution Series E3 is equipped with eight printing units (based on Pro UV technology), foil reversal system, cold foiling station, die-cutter as well as pre- and autoregister.

The press is configured to meet the changing needs and requirements of brand owners and consumers. The converter has been working with mid and high-level customers looking for high quality labels with different finishing and embellishment options. All three presses from Mark Andy purchased during last 10 years are equipped with several options to help Fano undertake ‘ambitious, demanding orders.’

With a bigger production capacity, Fano has accelerated its sales activities outside of Poland too.

‘It’s worth mentioning that export equals to more than dozen of our sales turnover and this number is still growing. When looking for and achieving new customers, we mostly act directly. Every year we try to be present at numerous trade fair events, either devoted to packaging or label markets, or the ones devoted to industries of our customers (cosmetic- or spirit-oriented events can be examples). It’s a direction we want to follow in 2022, too. We hope that trade fair industry will be back to normality next year,’ Boleslaw Jasinowicz said.

Tom Cavalco, executive vice president Mark Andy, said: ‘Our brand has been present at Fano for more than two decades. It’s a huge responsibility for us as a manufacturer and a vendor. Especially considering, that each successive press offers a very extensive configuration and numerous additional options. We appreciate a co-operation with FANO and the people who manage the company, as they are very tied to Mark Andy brand but also very open in direct contact. It’s a very important factor as it allows for fitting our offer to present needs of the printer, also considering a changing market environment.’

Boleslaw Jasinowicz said that Mark Andy’s equipment offers high quality performance and has ‘big experience’ with after-sales and service care offered by a local Mark Andy division. ‘We have undertaken all these aspects when considering a new press devoted for self-adhesive stock.’

Fano will move to a new headquarters in 2022 to be built from ground up. The converter is looking for a bigger facility to accommodate new investments and wants to offer its 50-people staff better work conditions. The manufacturing site will be constructed according to BREAM certification. It will consider different areas of sustainability policy. It will include a recovery system of the heat emitted by printing presses, a close water circuit and photovoltaics.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.