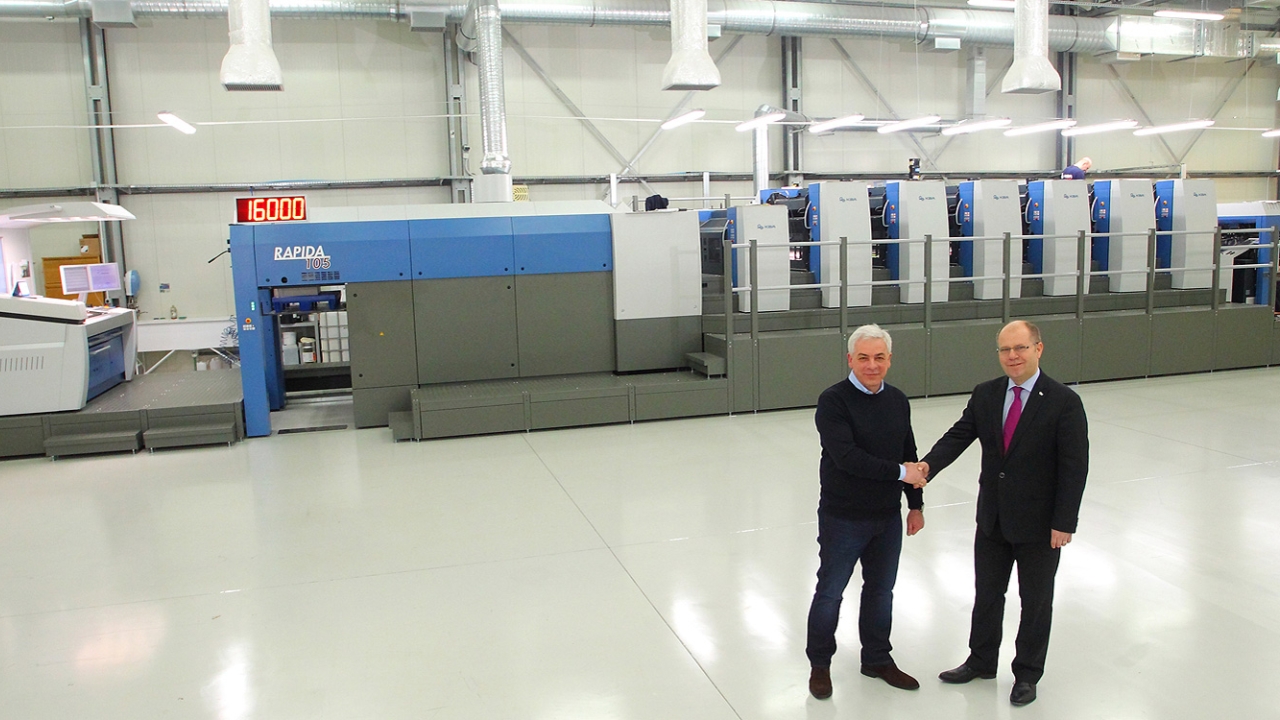

Intropak buys six-color KBA Rapida 105 hybrid press

Polish packaging printer Intropak Płochocki & Wspólnicy Sp.j. in Celestynów, near Warsaw, has installed a six-color KBA Rapida 105 with coater and delivery extension as it looks to extend its capabilities.

The Rapida 105 at Intropak is mounted on a 450mm (17.7in) plinth for printing packaging and is equipped with additional board and film packages that handle a maximum stock thickness of 1.2mm (48pt).

Automatic plate changing, CleanTronic Multi and CleanTronic UV washing systems, as well as non-stop rollers in the delivery, all contribute to short make-ready times, KBA said.

The press also features VariDry IR/TA/UV dyers in the delivery extension and delivery, as well as a UV interdeck dyer which can be positioned freely between the printing units.

As such, it is equipped for mixed operation with conventional and UV inks as well as finishing with water-based and UV coating.

ErgoTronic ColorControl for measuring color density, ErgoTronic Lab for color measurement and control based on L*a*b values, and QualiTronic ColorControl for in-line quality control all ensure a consistent high quality and low waste levels. In-line quality control was of particular importance to Intropak as it is an integral pillar of the firm’s internal quality management in accordance with ISO 9001.

Carton printer Intropak has a broad customer base consisting of clients from the music, cosmetics, food and electronics industry. Along with printing, Intropak offers various finishing services such as coating (including UV), laminating, gold blocking, embossing, and window cutting and gluing.

It has been using KBA equipment for over 12 years, and the new investment is part of an extensive package of measures aimed at improving production processes and the performance of the entire printing house.

Intropak’s management selected the KBA Rapida 105 hybrid press as it enables the use of conventional and UV inks in combination with various types of coating.

Intropak owner Dariusz Płochocki said: ‘Along with a larger sheet format, this press offers us a nearly endless array of possibilities in terms of inline finishing, which we aim to exploit fully.

‘With its extensive kit our new Rapida 105 has much more potential than its predecessors. It allows us to expand our product portfolio.

‘We are confident this new medium-format press will deliver a boost in quality and output, which was the case with our previous KBA presses.’

‘All of this, including a three-shift production schedule, contributes to a high level of customer satisfaction in Poland and abroad,’ added co-owner Katarzyna Kulisz. ‘It is important to our customers that we invest continually in cutting-edge technology and thus able to offer packaging with a special flair and added value.’

The order was placed from KBA CEE, the German press manufacturer’s subsidiary in the region. Jan Korenc, managing director of KBA CEE, said: ‘We are very pleased that Intropak, a firm with a good reputation not only in Poland but also internationally, opted for a hybrid sheet-fed offset press from KBA.

‘This press facilitates production with a raft of inks and coating. We hope that the new Rapida 105 will contribute to the dynamic development of Intropak, just like the firm’s previous KBA presses have done.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.