Label Technology adds Rotoflex VLI with EyeC ProofRunner for flexible packaging production

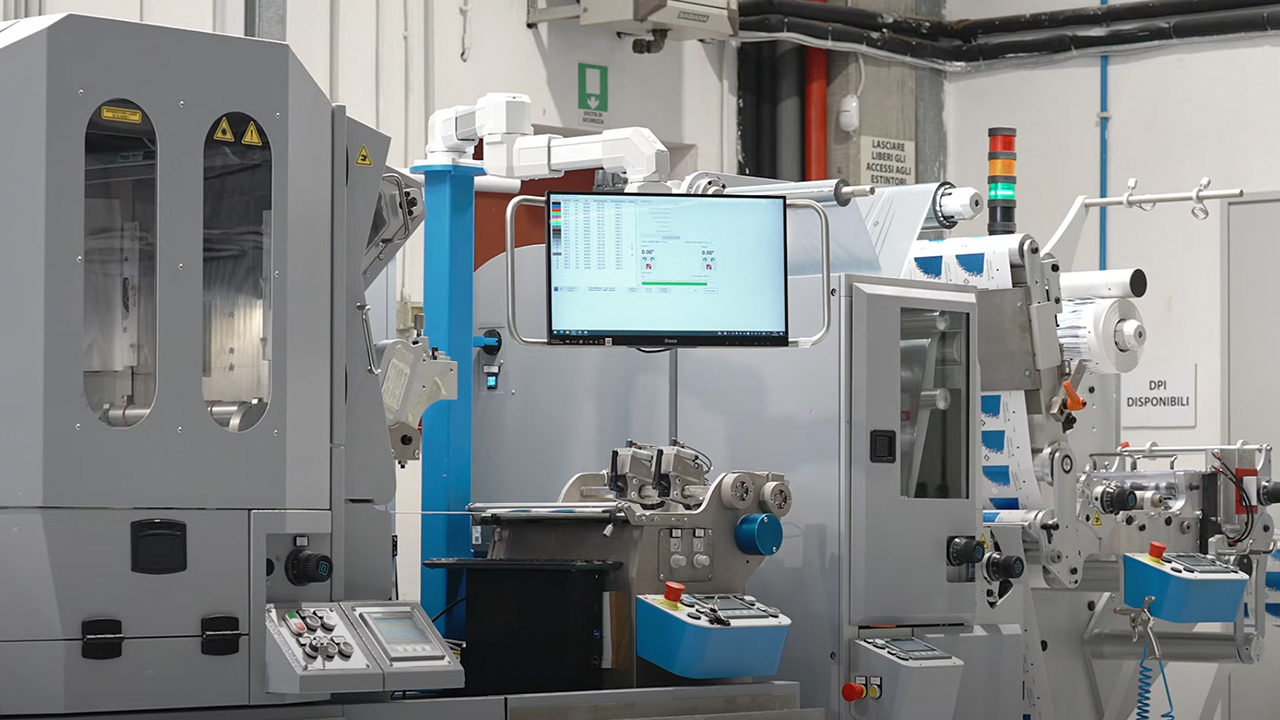

Label Technology, a North American printer that specializes in flexible packaging and pressure-sensitive labels, has purchased a Rotoflex VLI 700 inspection, slitting and rewind system for tension-sensitive materials, integrated with an EyeC ProofRunner 760 system for advanced print quality verification.

Designed for high-speed production of conventional labels, film and other tension-sensitive materials, the VLI is an inspection, slitting and rewind system available in web widths from 330mm (13.25in) up to 700mm (28.25in) and the capability of reaching speed of 2,000ft/min (610m/min). The Rotoflex report management system (RMS), a feature of the VLI, allows real-time production data to be collected from multiple finishing machines through a single interface for KPI such as run time, defects, production volume and scrap generation, as well as comparing outputs of multiple machines.

EyeC ProofRunner uses high-speed line scan cameras to continuously capture a high resolution colour image of the entire web. EyeC proprietary hardware and software then combine to identify and verify all printed items on the web automatically. Texts, graphics, colour variations, 1D and 2D codes are all inspected on 100 percent of the printed web.

Label Technlogy has also purchased a Mark Andy Performance Series P7 flexo press for complex print applications with an in-line EyeC ProofRunner 450 that monitors print quality, allows higher print speeds, reduced waste and increased operator efficiency. The P7 and VLI are both in full operation and running daily production.

Dave Bankson, president and CEO of Label Technology, said: ‘Our team initially saw a live demonstration of the VLI with an EyeC ProofRunner inspect, slit and rewind unsupported film at a very impressive speed at Labelexpo Americas 2016. As we were looking to add another finishing solution to our flexible packaging capabilities, this combined solution was an ideal fit, and has provided throughput improvements since its installation, performing at speeds of up to 500m/min with 100 percent inspection. We are extremely pleased with our Mark Andy and Rotoflex investments with EyeC ProofRunner inspection systems.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.