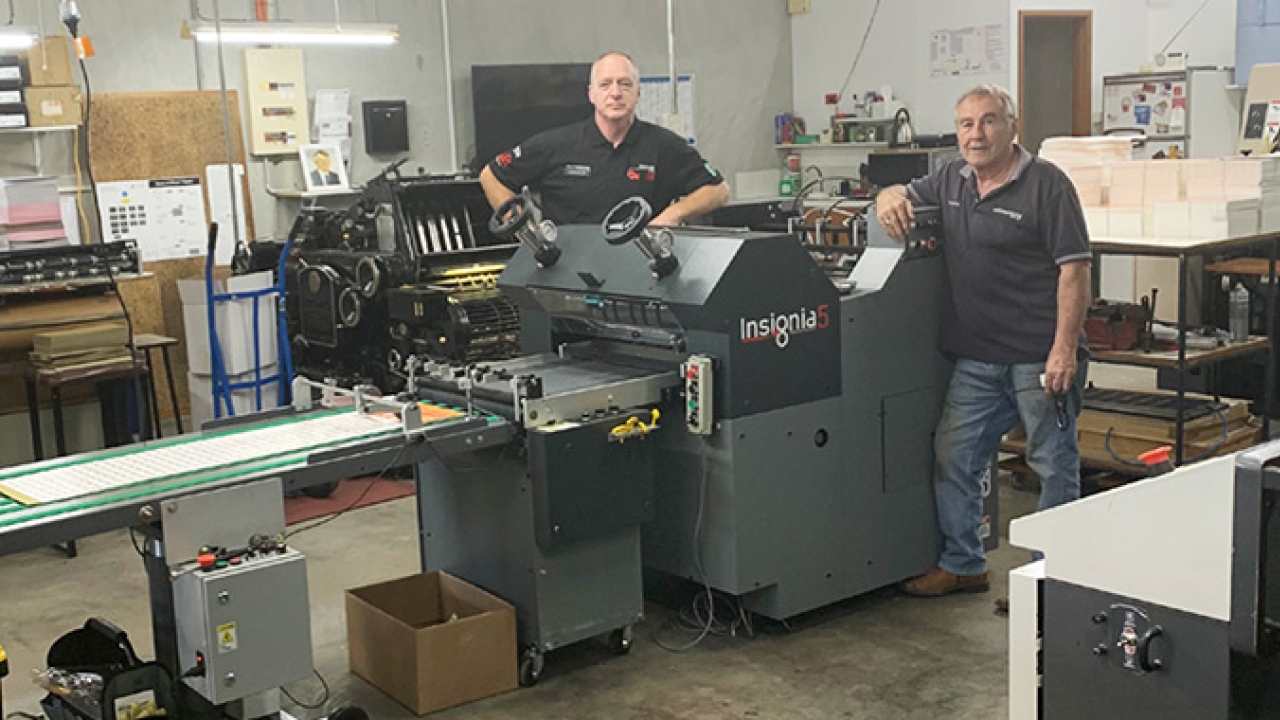

Mildura Printing invests in Rollem Insignia 5

Australian digital label printing company Mildura Printing has invested in a Rollem Insignia 5 digital die-cutter to improve overall productivity and expand its production capacity.

The Rollem Insignia 5 digital is a flexo-magnetic rotary die-cutter developed for short, medium, or long-run capacity, offering quick changeovers and die-cutting materials up to 30 pt. in thickness.

‘I saw a Rollem die-cutter in 2019, but the investment didn’t fit our plans at that time. So, when the necessity arose for us to get a heavy-duty die-cutter, as we had been using an old letterpress,’ said Lindsay Stephens, director of Mildura Printing. ‘I did look at a few other options, but none were as sturdy, speedy, and suited to what we were doing than the Rollem Insignia 5.’

The newly installed die-cutter offers Mildura Printing operational speeds of up to 5,000 sheets per hour and the ability to die-cut, kiss-cut, and cut-score an unlimited number of products, including labels, folding cartons, shaped direct mailers, and more.

‘Our productivity has increased since we installed the machine a few weeks ago. We’re adapting to use the machine for many other uses, such as die-cutting different products like plant tags for nurseries and promotional materials for supermarkets – anything that requires different shaped tags,’ added Stephens. ‘It also widens our product range as we can now venture into areas we couldn’t operate in before. Also, one of the amazing features of the machine is the ability to add elements to diversify our production lines even further.’

Before the investment in the Rollem machine, Mildura Printing had a good business but wasn’t getting the most out of its return. So, following its purchase of the Rollem Insignia 5, the company now has a reliable solution that meets its needs,’ commented Tom Ralph, managing director of Graph-Pak, who supplied and installed the new equipment. ‘The machine was fully operational three days after it landed in Mildura, and I don’t think it has stopped since, nor do I expect it to stop either.’

According to Ralph, the Rollem Insignia 5 allows Mildura Printing to be a more sustainable and profitable business moving forward.

‘The die-cutting was a very slow in-house process for Mildura, which also required a lot of outsourcing. This was eating up a lot of money plus involved more waiting time. Now, Mildura Printing can print and die-cut within minutes of the job coming off the printing press. The machine is simple to operate and is robust. If there was ever an issue, we’ll be able to send out trained engineers within an hour of Mildura’s plant as they aren’t located in a metro area. So, the business has a full package with us,’ concluded Ralph.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.