Omnicell invests MPS EXL-packaging flexo press

Omnicell, a converter specializing in high volume blister packaging based in St. Petersburg, Florida, has installed MPS EXL-packaging 680 flexo press to ramp up its production to meet the demands of the medicine packaging market.

Omnicell produces various single and multi-pill packaging for use in its autonomous pharmacy machines. Chris Hayes, manufacturing engineer and leader of the press initiative, and the board wanted to increase productivity while maintaining the Omnicell quality standards.

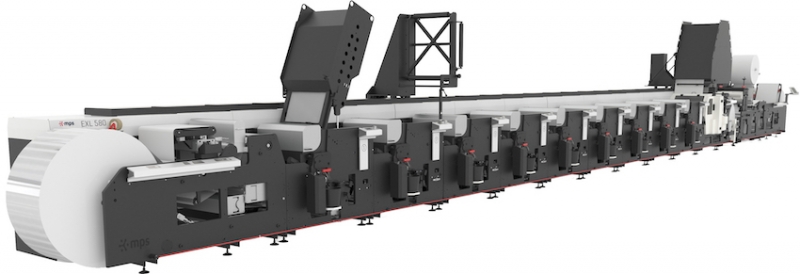

After rigorous OEM testing, Omnicell decided to purchase an MPS EXL-packaging 680 flexo press equipped to produce complex blister packaging in a single pass. It includes several OEM niche equipment, including hot-air dryers, automatic unwinders, inspection technology and a stacker.

The Omnicell press marks a record length built for MPS, with an astonishing length of 118 feet (36 meters).

Manufactured for blister packaging production, up to widths of 26in, the EXL-packaging press produces at speeds of over 500 ft/min.

‘It can do anything and everything that all other presses at the facility can do, combined,’ said Hayes. ‘It prints better, has quicker changeovers, is fully automated, modular and easy to maintain. Our MPS press is incredible. It exceeds all expectations and has become a valuable asset to our St. Petersburg operations.

‘The speed is almost intimidating, but after MPS field service engineer proved the press can run at record speeds for the long run, with no complications; he trained our operators to do the same and we began hitting our production goals easily thanks to him and the MPS service team.’

Additionally, the press was equipped with connectivity options, linking it directly to the MPS service team. According to Hayes, having the ability for MPS technicians to log in and provide remote support, software updates, troubleshooting directly to the machine has been phenomenal.

‘I’d recommend MPS to any converter looking to increase capacity. Their press technology, service and the whole MPS experience has been incredible. Watching the speed of the machine, the quality of the print, and witnessing the variety of applications possible, I know we made the right choice choosing MPS as our press partner,’ concluded Hayes.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.