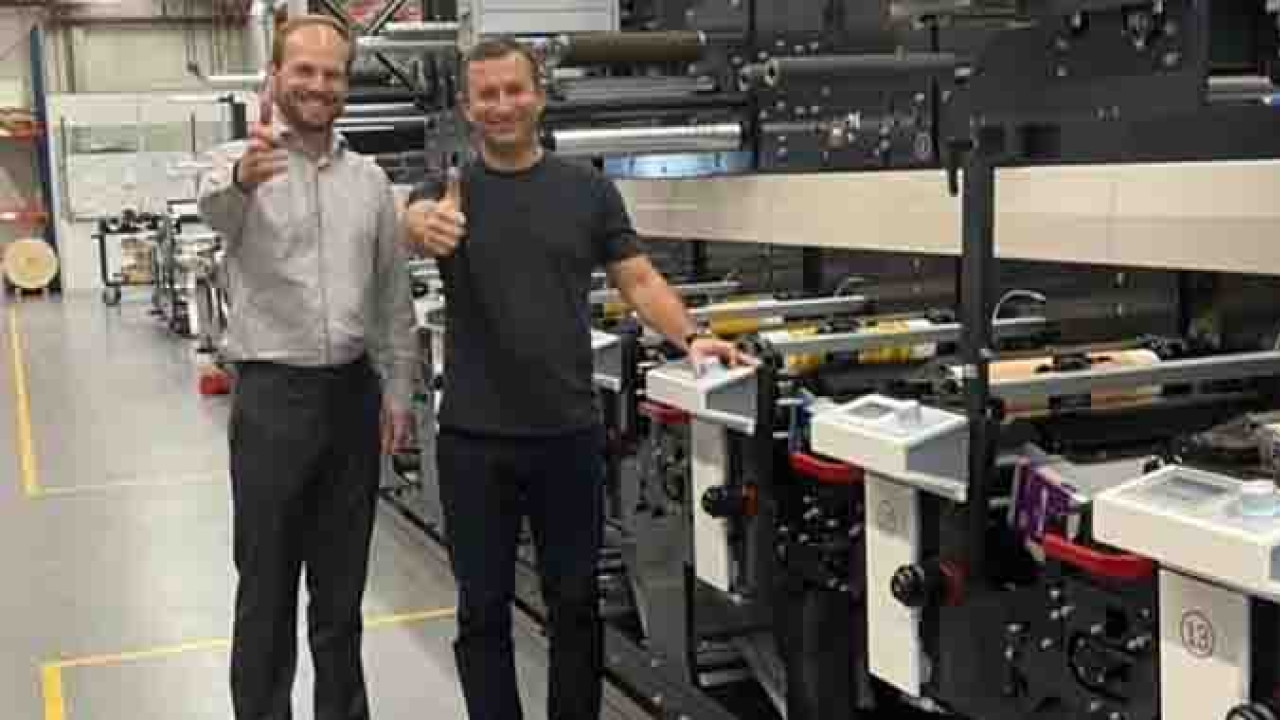

Russia’s Okil-Sato installs sixth MPS press

St Petersburg, Russia based converter Okil-Sato has installed its sixth MPS press, a 14-colour EFA 430 in November 2021. The new fully automated multi-substrate MPS EFA press, equipped with converting and embellishment options, was purchased to increase capacity for printing self-adhesive labels. The installation was led by Ogard, the Russian representative of MPS Systems.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.