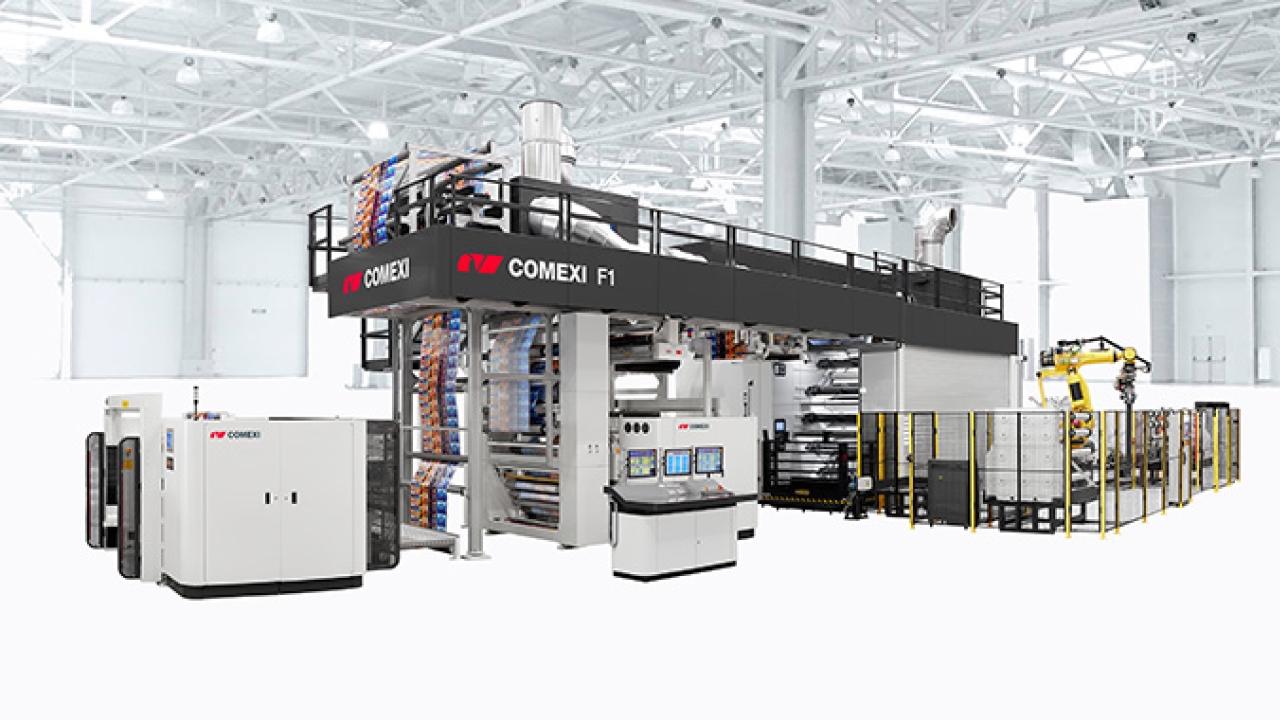

Termoplasti installs fully automated Comexi F1

One of the oldest converters in Slovenia Termoplasti-Plama has invested in a fully automated Comexi Flexo F1 with an anthropomorphic robot for changeovers of sleeves. Podgard plant will also become Comexi’s demo center focused on automation.

The agreement with the Slovenian company will allow Comexi to access a logistically strategic area and includes the creation of a showroom, which will be located in the same facility, allowing the company to demonstrate the advantages of fully automatic technologies

‘We decided to acquire a printing press from Comexi, they are a reliable, innovative and customer-oriented partner, which is absolutely necessary in today’s business world,’ said Sandi Prosen, CEO of Termoplasti-Plama. ‘During the testing of their machine and those of other suppliers, Comexi machines delivered unrivaled printing quality results at the higher speed, and with

‘It is also a great advantage that they integrate the manufacturing of the core elements of the machine, which includes the central drum, the printing mandrels and the printing unit frames. Furthermore, the company offers exceptional support for printing, laminating, and slitting technology. All Comexi current customers endorsed Comexi for its fast and efficient after sales service support,’ concluded Prosen.

‘We are very happy to collaborate with Termoplasti-Plama, a leader in its sector and a highly prominent company in the market,’ commented Alessandro D'Agostino, Comexi area manager of the Balkan countries. ‘From a logistics position, due to the location of

The collaboration will benefit both companies, as the new flexographic press will be installed in a separate Termoplasti-Plama facility, which will also be a Comexi European showroom and demo center.

‘This agreement allows us to exhibit our flexographic technology with a fully automatic robot to every customer interested in flexo technology. Furthermore, with this collaboration agreement, Termoplasti-

The F1 press is a

‘We were the first company to develop a fully automatic sleeve change system with an anthropomorphic robot, and today we have already installed more than 20 machines of this type worldwide,’ says D'Agostino. ‘This system offers the fastest changeover time in the market, making the whole process more efficient and productive.’

The Comexi F1 acquired by Termoplasti-Plama includes all peripherals to increase its efficiency, due to the incorporation of the patented ‘Cingular Real’ system, which offers 100% pressure and the register setup with minimum waste and color matching through ‘Cingular Match’.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.