Universal Adhesive Systems installs CL350 hot melt adhesive coater/laminator

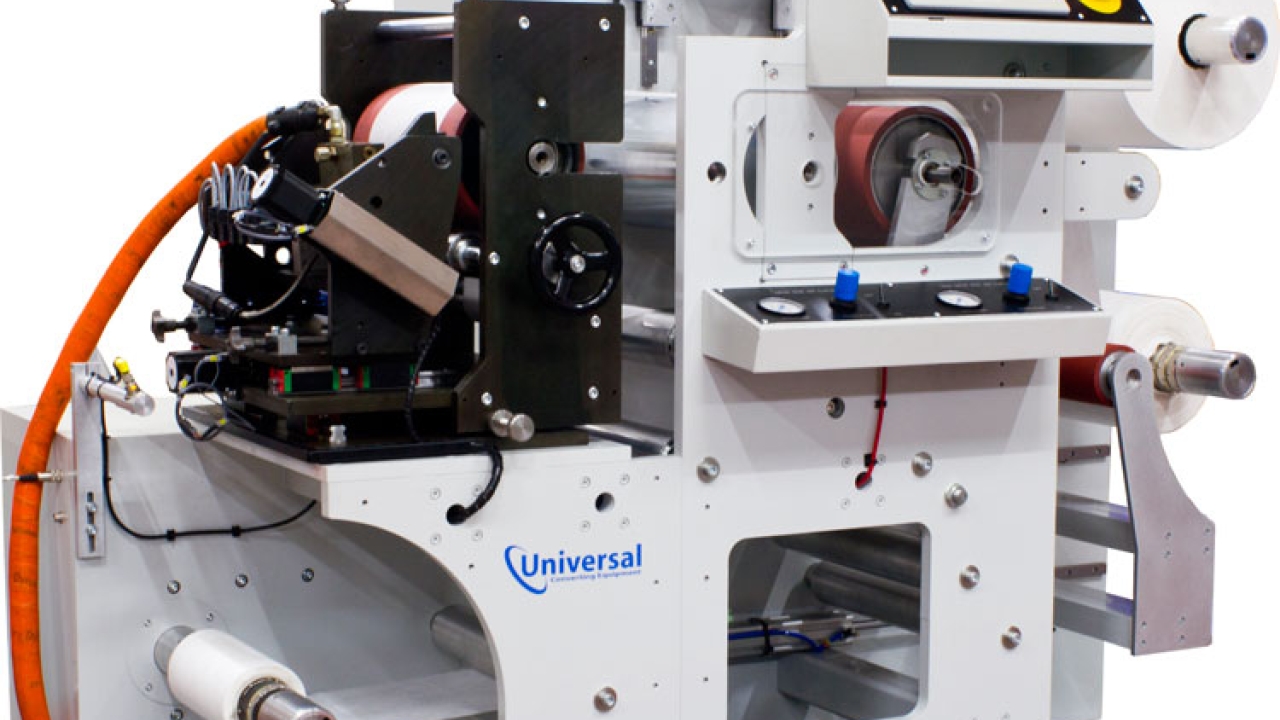

Universal Adhesive Systems has installed a CL350 hot melt adhesive coater/laminator from sister company Universal Converting Equipment to strengthen their respective positions as suppliers of converting machinery and adhesive application technologies.

The CL350 is capable of multiple coating types, including slot die proximity coating, CrossCoat curtain coating, high speed intermittent coating, spiral coating, spray coating and Dynafiber coating. In addition to the different coating types, the machine has been developed to handle a wide range of substrates including films, paper and nonwovens.

The automatic coating station on the CL350 was designed and built in Ipswich by Universal Converting Equipment. Adjustments on the coating station are made via a touchscreen and actioned by precision motors. The constant gap winding system ensures the best quality finished rolls are produced, it is claimed.

The CL350 is available for customer trials at Universal Adhesive Systems facility in Daventry, UK. The installed CL350 can operate at production speeds, so by running coating trials at the test facility in Daventry, Universal said customers can prove hot melt applications will work in live production environment.

Alan Jones, managing director of Universal Converting Equipment, said: ‘Universal Converting Equipment has grown rapidly in the last three years mainly driven by the introduction of our high productivity Universal X6 slitter rewinder. However, hot melt coating and laminating is an important and growing sector for us with machines being supplied on a worldwide basis. We are able to combine the high speed web handling and tension control systems developed for our slitters with the coating expertise of our sister company, Universal Adhesive Systems, to provide a complete package for our customers.’

Universal Adhesive Systems is a global supplier of technical adhesive supply and coating equipment for the converting and nonwoven industries. Universal Adhesive Systems has its own team of engineers and coating experts to provide systems and support for coating, laminating, print finishing, packaging and other applications.

‘The test facility at Daventry gives customers who may have little or no experience of this technology, the chance to test different materials, adhesive and coating techniques, so they can prove their product prior to investing in a machine,’ Jones added. ‘The close relationship with ITW Dynatec ensures we have the best hot melt feed systems and worldwide support. With both our slitting machines and our coating machines, we believe that being able to provide ongoing support for our customers is vital to ensure they are satisfied and come back to us with more orders in the future. The use of Internet based remote diagnostic systems, high quality components and our dedicated support team to ensure this support is available.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.