Zircon invests in India’s first SPGPrints rotaLEN

Zircon Technologies has invested in an SPGPrints rotaLEN direct laser engraver, to provide a digital pre-press workflow for imaging high volumes rotary screens at its Dehradun factory.

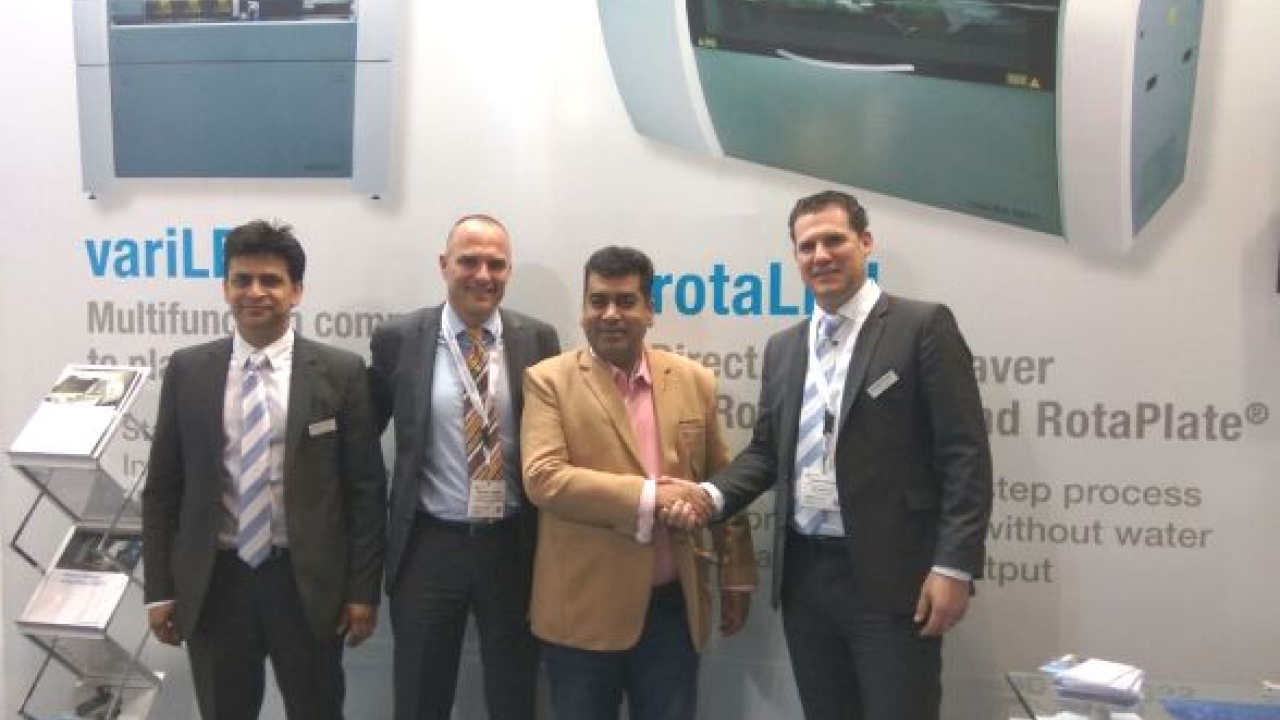

The sale was agreed at Labelexpo India on the Stovec stand where the full range of SPGPrints’ products for labels has been presented.

The rotaLEN engraver offers fast, clean, high-definition (HD) screen imaging with minimal manual intervention. It will complement Zircon’s Omet Varyflex V2 press that incorporates three rotary screen units for value-adding label enhancements and its newly ordered 10-color Omet XFlex with two rotary screen units. The rotaLEN will have the capacity to supply screens for both presses.

The rotaLEN engraver features CO2 lasers that burn the emulsion on the mesh, in a dry, single-step and fully digital process requiring no chemicals, film, or exposure and drying processes.

Zircon will be able to offer screen-printed small text, meeting the demand for providing more information on a label without compromising clarity. rotaLEN engraving cycles are as short as 30 minutes per screen. Jobs can be recalled from the database and repeated to identical specifications.

In the unlikely event of screen damage during a print run, therefore, Zircon can perform an immediate remake and continue production without excessive downtime.

The rotaLEN engraver at Zircon will engrave SPGPrints’ RotaMesh seamless nickel screens, chosen for their durability, re-usability and ability to be re-imaged several times.

Hank Guitjens, commercial manager label printing at SPGPrints, commented: ‘Zircon seeks equipment with the highest standards of performance at every step so they can deliver the stringent quality demands, often within short lead times. The rotaLEN direct laser engraver in combination with RotaMesh screens provides the precision and flexibility to do this.’

Zircon Technologies sees the rotary screen process as the key to offering high-value solutions for brand owners in sectors such as home care, food and drink, automotive and industrial, personal care and security printing. The demand for product differentiation and high-perceived value products has accelerated rapidly in the Indian market. Spot varnishes, metallic effects, fine line designs and textured finishes can all be applied by rotary screen printing, and the detail possible with screens imaged with the rotaLEN will deliver high quality finishes over very long runs.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.