Cheshire invests to meet growing demand

- Cheshire to produce bespoke engravings to suit the most challenging flexo and coating applications with new laser

- Company’s fifth 500W laser

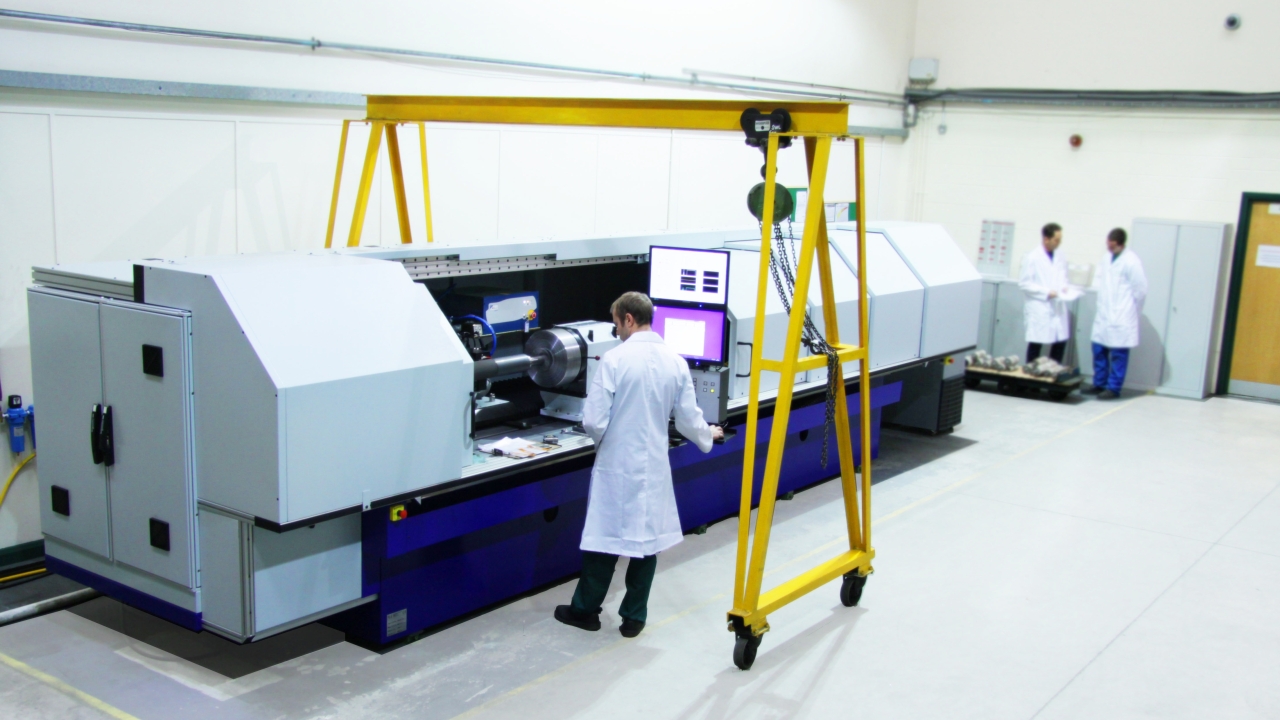

Cheshire Anilox Technology has installed another Fibre laser to meet a surge in demand for its high release engravings.

The investment, which cost close on £500,000, was made in collaboration with Applied Laser Engineering. It is the company’s fifth 500W laser, and, as the most advanced of its kind, will allow Cheshire to produce bespoke engravings to suit the most challenging flexo and coating applications.

The purchase completes a major investment project undertaken by the company in the last 18 months, which totals £1.5 million overall.

Equipped with the latest multi-beam technology for precision and quality engraving, with full programmable cell geometries, the new 4.5m laser can produce engravings from 25-2,000lpi.

It features a custom pulse to provide graphic control and creation of bespoke cell shapes, and the latest MAD engraving mode that offers improved control of cell shapes for maximum release and consistency, with less than a one percent cell volume variation across the roll surface.

Sonia Arcos, technical sales director of Cheshire Anilox Technology, described the purchase as an historic moment for the company, and, ‘evidence of our long-term commitment to continuous improvement in quality and service as we expand in the global markets for flexo and offset.’

Managing director Paul Smith added that recent investments in new coating, finishing and laser equipment have been necessary to ensure sustainability and improve quality and delivery, and provide the capacity the company needs to stay at the forefront of anilox innovation.

Read more on Cheshire Anilox Technology here

Read more on anilox rolls here

Read more about ancillary equipment here

Read more news from across Europe here

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.