Manage the environment: improve profitability

Becoming a more environmentally conscious label converter is a key step to an enhanced bottom line and improved profitability, argues Mike Fairley

Over the past few years the topics of sustainability, waste, carbon emissions and the environment have been receiving ever increasing exposure and attention in the media. Climate change, sustainable forests, petroleum resources, transport and distribution costs – all are beginning to have a growing impact on the world of labels. Yet, relatively few label converters to date seem to have taken these topics seriously, or have implemented measure to improve their environmental performance. So what are the challenges?

Concerns about the environment and global climate change were already beginning to be raised as far back as the 1970s. At that time it was mainly about the earth cooling. Later came concerns about aerosol gases destroying the ozone layer, with Governments around the world agreeing that damaging CFC gases had to be replaced with more environmentally friendly alternatives.

Today, the whole environment, sustainability, climate change and waste debate have shifted dramatically. Rather than just being about greenhouse gases, a whole raft of legislation, guidelines, directives, and protocols have been introduced over the past 10 or 12 years, placing an ever increasing impact on the label industry and its suppliers.

Driven by Governments, environmental and consumer groups, brand owners and retail groups, the label industry has already been adopting the use of more environmentally friendly materials from managed forests, thinner materials, sourcing of alternative tree-free fiber papers, new types of films, recycled content materials, recycle compatible adhesives (RCAs) and VOC-free inks and solutions.

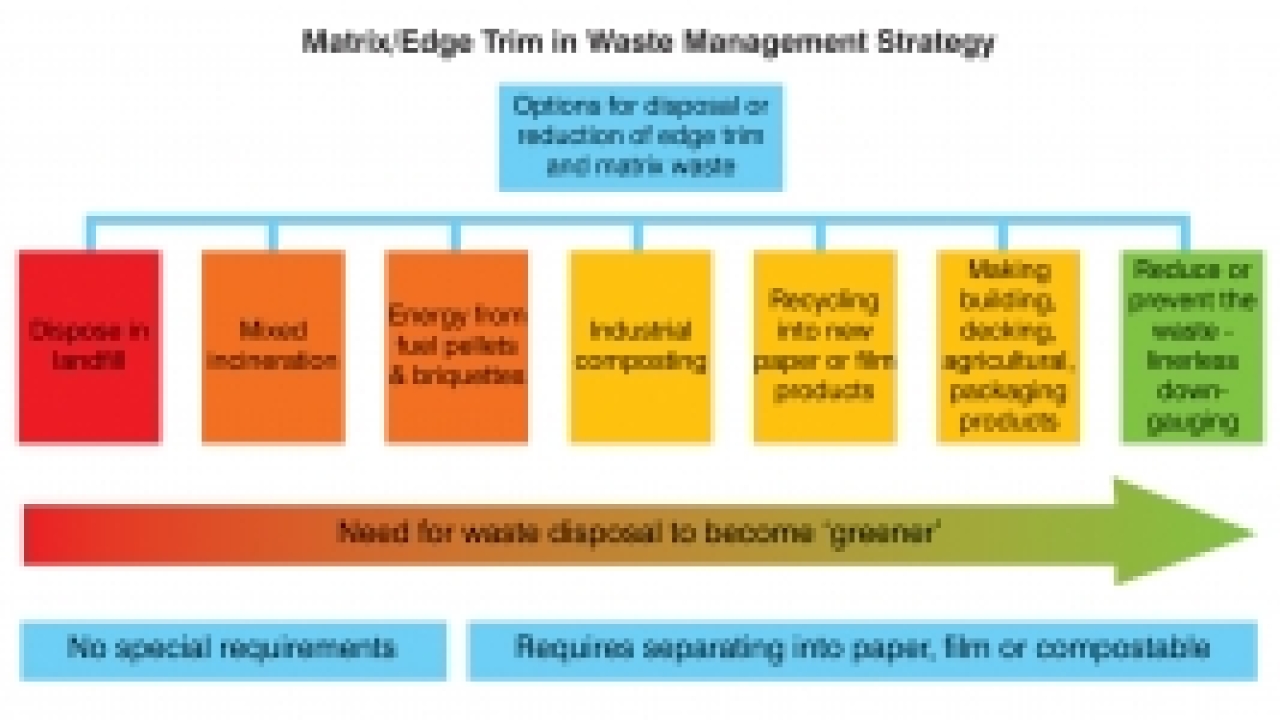

More and more Governments have banned (or are looking to ban) packaging and label waste going to landfill. This puts a major pressure on the label industry as around 80 percent of label waste today – including release liners – currently goes to landfill worldwide. Waste collection and recycling of edge-trim, matrix and liner waste has started, but has many challenges to overcome before it becomes a universal solution or industry standard.

Carbon emissions and energy usage data documentation is now expected in much of the label industry and, in some regards, is being addressed. Demand for data transparency will continue to progress. The cost of energy is increasing rapidly on a global basis and the label sector needs to do much more to reduce energy consumption, to become leaner in manufacturing, to limit emissions, to design recycle compatible label constructions and to become cleaner and ‘greener’ in its operations.

‘Much is already being done to aid the converter. TLMI, FINAT and other label associations have introduced, support and encourage environmental schemes – such as TLMI’s Label Initiative for the Environment (LIFE) program – or the converter can alternatively implement ISO 14000 or tailor an EMS to suit their business needs. Many label converters already have to comply with Scorecard programs introduced by their key customers, such as Walmart and Procter & Gamble. Demand for label converters to become accredited or work with these types of programs, again, will continue.

The industry’s major supplier companies, whether labelstock producers, press manufacturers, UV-curing systems suppliers, ink and platemaking companies, etc, are today all playing their part, but much more needs to be done to educate and inform the label converter and their customers about what can be done, and what needs to be done to remain successful, sustainably, moving forward.

Despite all of the above taking place, all too frequently the message from the label producer seems to be either that their customers are not demanding it, or it is too expensive to comply with the many and changing environmental performance requirements. Well, that is all now changing rapidly. The ‘Environment and Sustainability’ issue is now fast rising to the very top of the converter’s agenda.

More and more brand owners and label buyers are building in the use of sustainable materials as part of their buying process. Many are making zero waste to landfill part of their five-year or 10-year strategies. Others are looking to include topics such as carbon footprint and lifecycle analysis into their buying plans.

Put together and done well, the strategies required for a label converting business to become more environmentally and sustainably conscious are almost identical to strategies to become more profitable. That is, to reduce energy, reduce waste, reduce production costs, minimize set-up time, reduce water consumption, reduce fuel and vehicle costs.

If they can also reduce their waste-to-landfill disposal costs, obtain money from sending filmic materials for recycling, generate energy from solar panels, return or re-use incoming packaging, recycle left-over ink, etc, then that is an added bonus. In simple terms, being an environmentally conscious label converter is a means to being a profitable label converter. Surely that’s what everyone aims to be?

So let’s take a few areas where implementation of an environmental management policy can pay particular dividends:

Label materials selection and usage

Whatever the type of label − self-adhesive, wet glue, sleeve, wrap-around, in-mold − they all make use of a paper, plastic, synthetic or other material to carry the printed image, which is subsequently applied to a wide variety of products or containers. This label substrate is one of the key elements that the end user pays for and, not unnaturally with today’s global environmental pressures, has also been coming under increasing pressure to be seen as ‘greener’, more sustainable and easier to dispose of.

Today, major label user organizations – the brand owners, retail groups, consumer products manufacturers, etc – are increasingly presenting their label suppliers with environment or sustainability assessment documents, with requirements for materials efficiency, for the use of responsibly sourced raw materials (made in an efficient, ethical and environmentally responsible way), for third-party certified (CoC) materials supply chains, transparency about where and how materials have been produced and on the handling and disposal of materials waste.

Put together, all these initiatives have already led to lighter and thinner label materials, sustainably managed forest paper products, recycled content in label papers, chemical free label papers, biodegradable substrates, compostable label stocks, corn starch and other bio label films, recyclable grades, environmentally benign or recycling compatible adhesives, chain-of-custody certification and a whole host of label waste recovery, recyclable and re-processing solutions.

Label converter production performance, including clean manufacturing

The production environment in a label converting plant is one that uses a wide range of materials, inks, adhesives, coatings and varnishes, chemicals, oils and greases, water, energy and light. A number of studies have highlighted areas within the production environment and on or around a label press where wastage may occur and improved environmental performance, energy efficiency and waste reduction need to take place.

Undoubtedly one area of the production environment that is increasingly coming to the fore in environmental management and scorecard systems is the reduction of energy costs and greenhouse gas emissions. Actions to be taken by label converters include measuring and taking steps to reduce their greenhouse gas emissions − which have been shown to be responsible for much of the increase in global average temperatures.

The aim for label converters, therefore, should be to cut fuel and utility costs by firstly measuring energy usage and then by improving energy and fuel efficiency. Where feasible, renewable energy sources − such as the sun, wind or water − should be used, perhaps even generating renewable energy on-site, as some label converters are starting to do.

Solid waste management and disposal in the label plant

When talking about wastage in the label plant, the converter perhaps initially thinks of production waste such as make-ready waste, handling waste, running waste (print faults, miss-register, etc), matrix and edge trim waste, reel ends, cores and the like. Depending on the type of label and process, this may include paper, plastic, metallic and metallized materials, all kinds of self-adhesive laminates, synthetic materials and other day-to-day wastage around the printing press.

Recent research has indicated that an average of 17 percent of all incoming labelstock materials are lost within the label production plant, leaving just 83 percent as finished labels saleable to the customer. This figure excludes matrix, edge-trim and liner waste. The best label plants have this wastage figure down to no more than three or four percent.

Down-gauging and light weighting of label paper and films will become more common, new sources of paper fibers are being encouraged, bio-plastics have been developing fast, bio-degradable adhesives will be increasingly needed for composting applications, while recyclable and recycled materials will be in higher demand.

However, wastage in the label converting plant is far wider than just substrates and the concern of the press operator. It can include all kinds of general office waste, packaging waste from incoming goods (such as cardboard and corrugated boxes, plastic films and shrink material), reel or sheet material wrappers, processing chemicals in pre-press or plate-making operations, old or damaged printing plates, wooden pallets, soiled rags and cleaning materials, ink containers and waste inks, paper towels, electrical equipment and batteries, even garden waste. Almost all of these items can be recycled, with some even creating an income stream.

A label converter’s solid waste management program therefore needs to cover all areas of wastage, and wastage reduction programs established, monitored and improved. All processes should be constantly refined to ensure that waste − of any kind − is minimized.

Product performance

Global brand owners, retail groups and other leading buyers are increasingly requiring their suppliers of packaging and labels to submit a wide range of data and information on their packaging/labels and their environmental and sustainability performance. This information may include:

- Calculating a carbon footprint and reporting the percentages of greenhouse gases utilized during sourcing, manufacture and transportation

- Meeting market and environmental criteria for performance and cost

- Calculating the product/package ratio and the environmental impact of transportation

- Calculating and optimizing recycled content, disposal options and recovery value

- Introducing renewable energy and product innovation

- Ensuring the product is manufactured using clean production techniques and best environmental practices

- Providing supply chain transparency and third party certification

Much of what label buyers are seeking in relation to environmental, sustainability and product performance requirements are again based on guidelines set out by the Sustainable Packaging Coalition (SPC), an industry working group dedicated to creating a more robust environmental vision for packaging – including labels and labeling.

According to SPC, implementing the guidelines is intended to eventually lead to a world ‘where all packaging is sourced responsibly, designed to be effective and safe throughout its life cycle, meets market criteria for performance and cost, is made entirely using renewable energy and, once used, is recycled efficiently to provide a valuable resource for subsequent generations’.

Transport and distribution

Transport and distribution is indispensable to the supply chain of any business – whether goods in or out – and in today's competitive business environment, savings and performance gains from logistics and transport can provide a competitive advantage. Some companies have even introduced the concept of ‘Desk Miles’ into their operations. This is the distance products travel during manufacture, from raw materials to finished goods and onward to the customer. Other factors include purchasing more fuel efficient vehicles, use of optimization delivery or sales visit software, new route schedules and shared user schemes.

By using vehicles more efficiently, companies can make significant financial savings through reduced fuel costs and less wear and tear. It can also make financial savings from more cost-effective use of employees' time and by unlocking the potential of land previously used for parking. All businesses have a responsibility to ensure that any vehicle used at work is roadworthy and complies with exhaust emission standards.

To summarize:

Becoming a more environmentally-friendly and sustainable label converter makes good business sense. It reduces wastage, improves efficiency, builds closer links with customers, enhances the company’s status in the community – and improves the bottom line and profitability. Something that every label converter should aspire to.

Note

This article is based on the recently published Environmental Performance and Sustainable Labeling – A ‘How to’ guide to becoming a ‘greener’ label converter and label user book now available through the www.labelsandlabeling.com bookstore.

Pictured: Some of the many options now available for the disposal of edge trim and matrix waste

This article was published in the L&L Yearbook 2012

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.