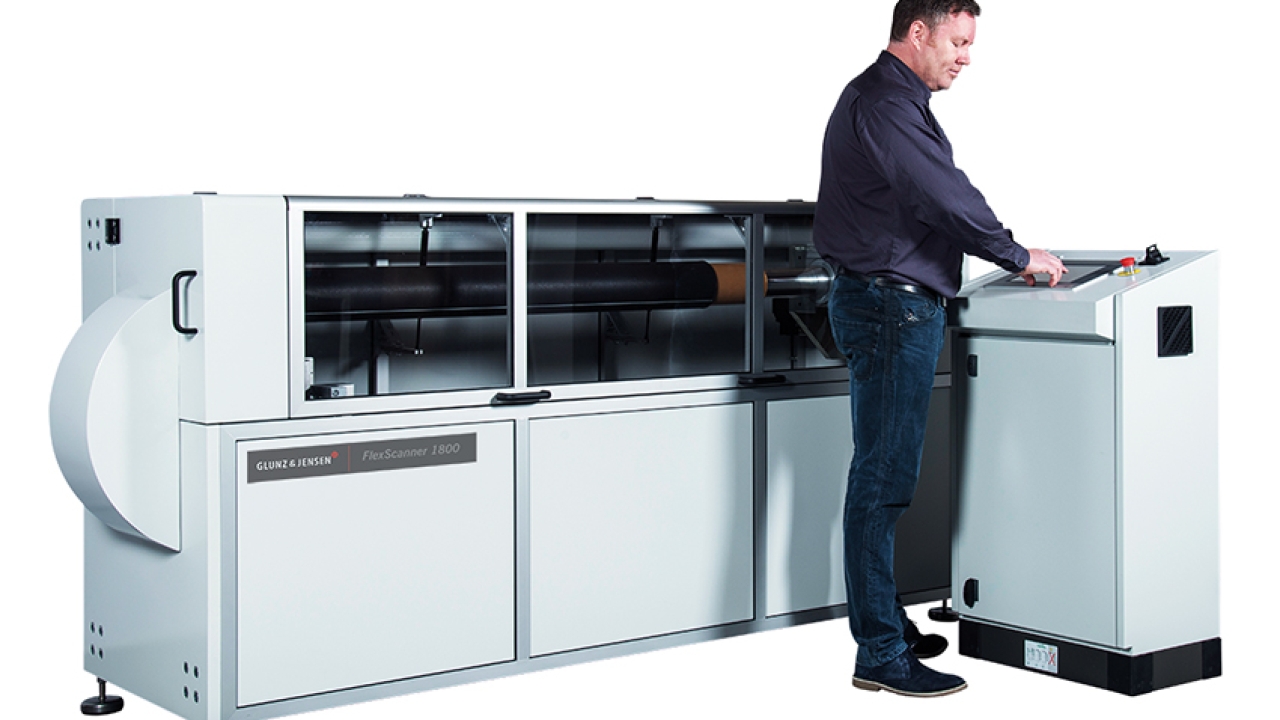

Glunz & Jensen launches FlexScan 1800

Glunz & Jensen has launched FlexScan 1800, an inspection tool for flexo sleeves to enable trade shops and converters to take full control of their production quality.

FlexScan 1800 digitally scans for low and high spots on round sleeves, thereby eliminating the need for a full test run on a printing press, according to Glunz & Jensen. FlexScan delivers a quality report (PDF or in print), with relief depth/height that is used to document the quality of incoming or outgoing sleeves. This process can be done in 20 minutes.

Following two years of close development process with its client, RC Group, Glunz & Jensen has introduced FlexScan 1800 as a ‘ground-breaking new element in the flexo pre-press production line’. The company said FlexScan 1800 enables trade shops and converters to exercise full control of sleeve quality before going on press, helping to eliminate production stops and optimizing press runs.

‘This will enable our customers to cut repro time up to 80 % on each sleeve or adaptor and secure an optimal prepress workflow along with the highest possible print quality,’ commented Søren Jørgensen, Glunz & Jensen general manager.

Henrik Kofoed, group sales manager at RC Group, added: ‘I believe that FlexScan 1800 will deliver a return on investment within a maximum of two years, depending on the amount of sleeves produced. The FlexScan makes history by innovating the entire process of flexo plate production around the world. Finally, the flexo market will have a tool to benchmark quality, and be able to work with international quality standards and documentation.’

FlexScan 1800 is available globally and can be seen at Glunz & Jensen’s flexo centre in Rosate, Milan.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.