Hybrid Software releases Packz 6.0

Hybrid Software has released the new version of its Packz software introducing artificial intelligence (AI) automations, revamped user interface and extended complementary warping technology.

‘In the prepress world, we understand that operators have their own ways of working. Instead of forcing Packz users to do things our way, Hybrid Software has worked hard to provide flexibility, so every user feels comfortable using our software,’ commented Patrick Coussement, Hybrid’s chief operating officer. ‘Since the first versions of Packz, users could already personalize the interface. With the new Pactions in Packz 6.0, they can now also personalize the functionality and tools, which leads to a higher level of productivity and performance.’

The new version can now record and edit a series of routine tasks and store them as Pactions, that can be played back at any time on the entire design, a selection or as part of a custom tool. It can be also merged with Cloudflow Packzflow automation on the server.

Pascal Wybo, product manager of Packz said: ‘In order to succeed in a highly competitive label and packaging supply chain, companies are constantly looking for opportunities to improve the productivity of their prepress operations. Hybrid Software fulfills this need and accelerates the relentless pace of automation by offering complementary Pactions.’

Hybrid has also introduced a new user interface called Nebula aligning the user experience with Clodflow. With PDF/X-4, the packaging industry will benefit in their transition from classic to digital printing technologies, or when having to supply ready for print designs. Text is intertwined with almost any label and packaging design.

The VDP technology have been furthered improved to allow for the populating of executed variable data into repetitions and automating of lead in and out for digital finishing and rewind equipment.

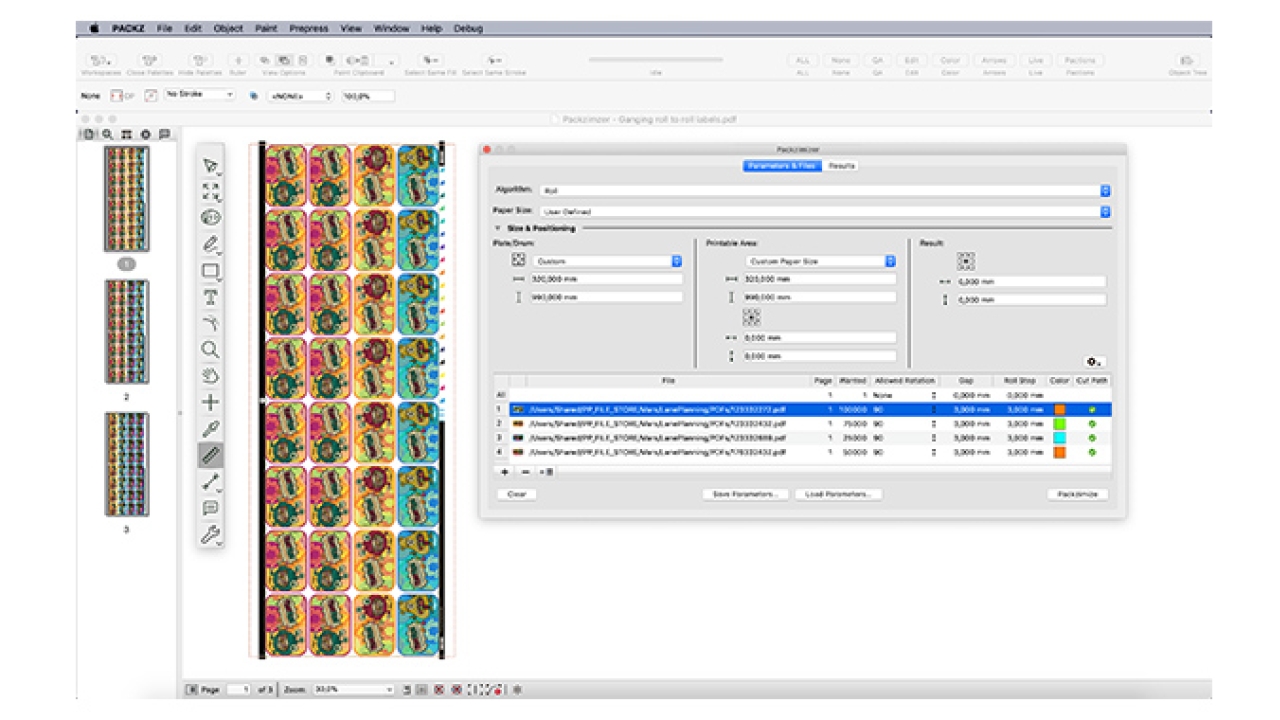

The new Packzimizer module uses artificial intelligence to I gang label or packaging designs on quantity and outputs print-ready impositions for web-fed presses. It reduces down-time, increases productivity, and can be driven from a CSV, thus linked to an MIS or enterprise business technology. The new AI algorithm also lends itself to creating concise and predictable cost estimation and production planning processes.

The step and repeat technology has been extended with push-button separation masking for staggered flexible packaging plates. It allows repetitions to be mounted on a cylinder in a seamless way simply by positioning the seam in between the printable objects.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.