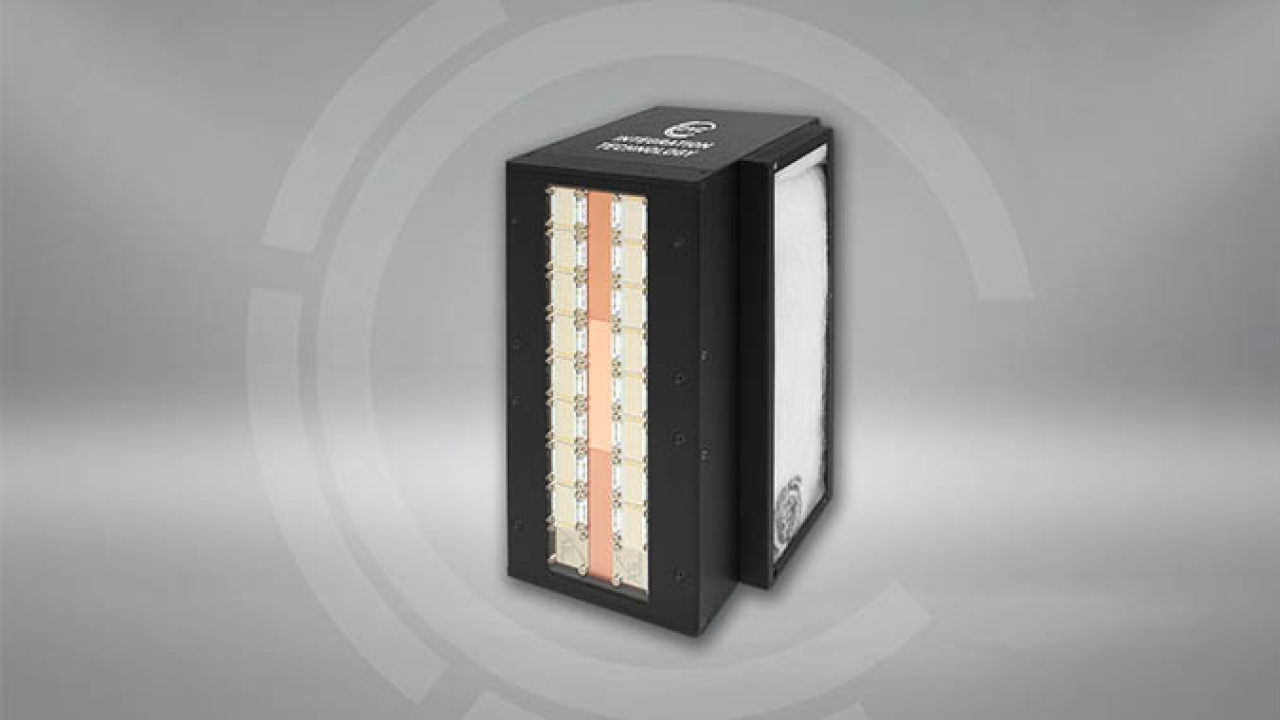

Integration Technology launches high dose UV LED lamphead

Developer of UV LED and UV Lamp technology Integration Technology has launched DVZ high dose UV LED curing system. The DVZ 14w/cm² double row, air-cooled, UV LED system is a high dose lamphead formulated for single-pass, coding and marking and label applications to maximize productivity and meet the growing requirement for higher production speeds.

The DVZ LED head is fitted as standard with Integration Technology’s XT 8 booster technology. It is equipped with VARIcool auto-adjusting cooling system for maximum UV performance 24/7.

David Johnson, sales director, Integration Technology, commented: ‘Integration Technology specializes in enabling our customers to meet the evolving demands of their markets, and to do this we take a consultative approach to product development, listening to customer requirements and using that information to inform our state-of-the-art UV LED solutions. The DVZ high dose UV LED curing systems are the result of the need to meet market demands of higher production speeds with an air-cooled alternative, allowing users to maximize efficiency and target growth in the competitive coding and marking and label sectors.’

The LED heads come with four alternative wavelengths, or a mixed wavelength module and are fully scalable in length lampheads in 30mm steps. Switch mode power supply unit ensures global compatibility.

The DVZ headlamps offer a range of powerful features, including ready to use immediately after switch on, with no warmup or cooling times. LEDs have a service life greater than 20,000 hours. The XT8 LED booster technology delivers a 30 percent boost in efficiency for the same current input, according to the company.

Addressable as standard, it offers width switching or zone selection. Constant current power means no gaps in output by PWM (Pulse Width Modulation) control.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.