INX introduces GelFlex-EB inks for flexible packaging

INX International Ink has introduced GelFlex-EB gel-based inks for CI flexo printing, offering print quality similar to gravure and providing a cross-linked, durable ink film that eliminates the need for a lamination layer, therefore reducing costs and total package weight.

‘We understand there are specific expectations of brand owners, converters, and printers, ranging from maintaining the print quality of graphics to providing yearly cost reductions through improved efficiencies and package light-weighting. GelFlex-EB inks address these concerns and present several opportunities,’ said Renee Schouten, director of marketing at INX.

In addition to food packaging, new inks can be used for household, industrial, outdoor, pet food, and pet care products.

‘Printers can reduce their overall ink consumption and experience energy savings, compared to conventional solvent or water-based flexo inks,’ added Schouten. ‘Additional cost savings are possible by eliminating lamination layers for flexible packaging and using various decorative and special effects coatings in their place. From a presentation viewpoint, these inks also open the door for new point-of-sale interactions and experiences with consumers.’

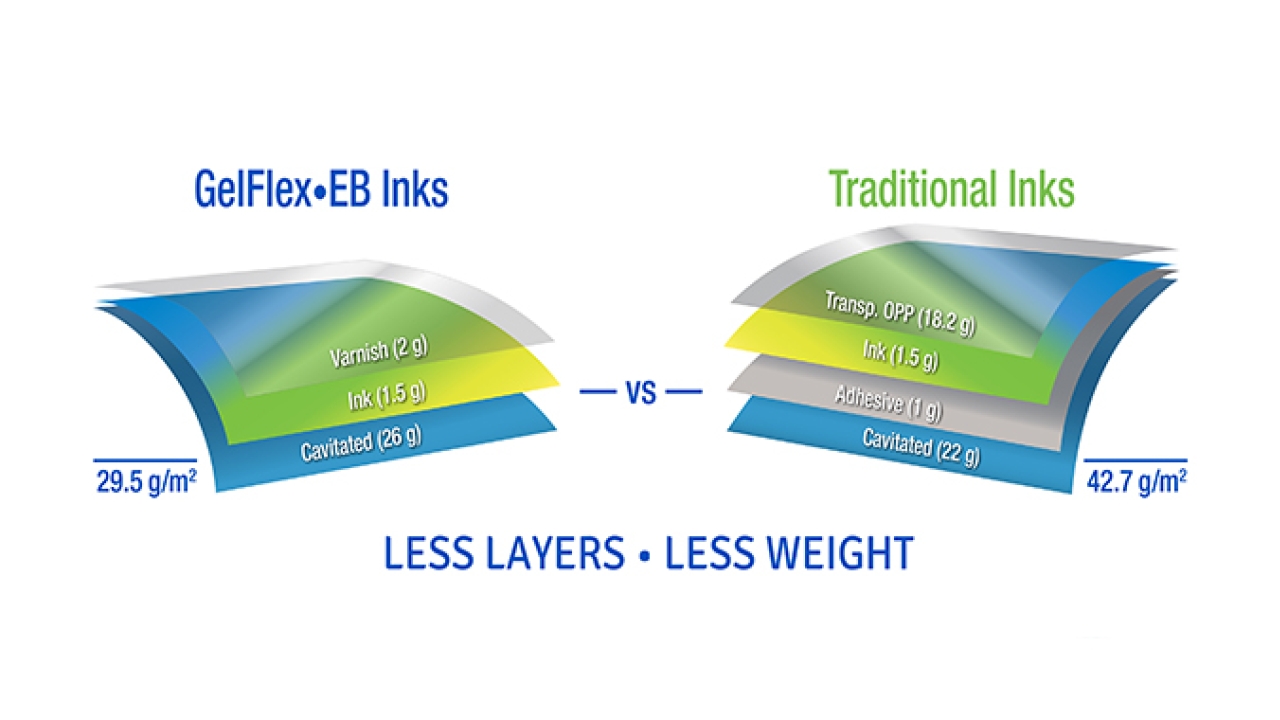

As a gel-based ink, GelFlex-EB is sufficiently fluid for CI flexo printing and thickens quickly for high-speed wet ink trapping. As an option, gloss, matte, and other decorative or special effect coatings can be applied in-line. A single EB dryer cures the combined structure at the end of the press to create a cross-linked polymer matrix. According to INX, using GelFlex-EB instead of traditional inks can result in a 30 percent weight reduction of the lamination layers.

The benefits of GelFlex-EB also extend to better print quality. A finer line screen and lower BCM anilox counts result in better tonal value and higher line screen plates and contrast range. INX also claims that in addition to more predictable print quality, printers will find smooth vignettes and solids, higher details in full-color images, and detailed brightness in high light zones.

‘With GelFlex-EB being a low migration ink and meeting various food packaging compliance standards, it is a safe and sustainable choice. The dramatic reduction in solvent and improved recycling attributes is part and parcel with increased efficiencies and lower costs. Printers will experience higher productivity with ultra-high press speeds and no distortion on the web, as well as extended gamut printing, higher opacity white, and less material waste.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.