Maxcess launches the RotoMetrics AccuAdjust Dual Adjust Anvil

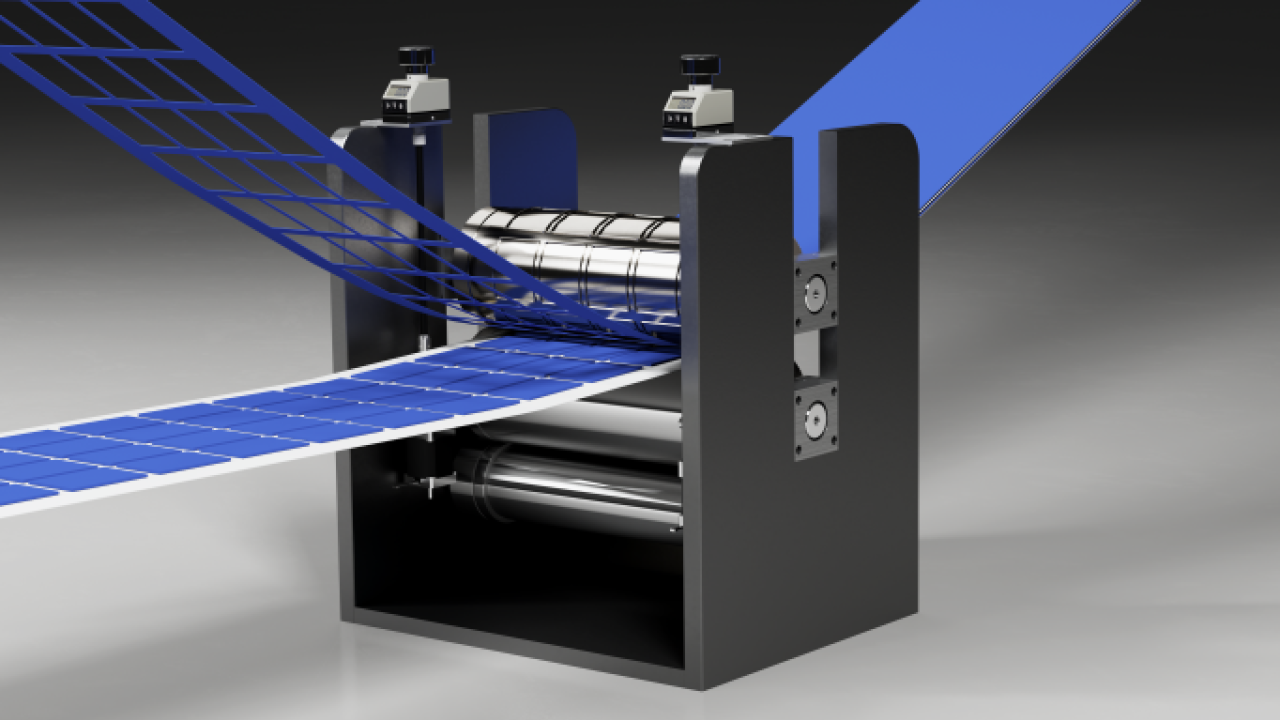

Maxcess has launched RotoMetrics AccuAdjust Dual Adjust Anvil. Featuring easy-to-use digital controllers on the front of the die stack, quick installation into a press and automation-ready motors that ship with the unit itself, the AccuAdjust paves the way for fully automated anvil adjustment upgrades that are ready when you are, says Maxcess.

'We designed the new AccuAdjust from the ground-up with our global R&D team to give customers an intuitive and powerful tool to control liner variation that our customers are seeing on a daily basis,' said Nadine Powell, global product manager for RotoMetrics, a Maxcess Brand. 'With shortages in skilled labor, liner variation changes and material supply issues that every press operator is facing, the new AccuAdjust will be a welcomed solution to cut perfect labels, while reducing scrap from common liners such as PET, Glassine and Kraft.'

Featuring easy-to-access dual-adjustable controllers on the front of the die stack and backed by a global service and support infrastructure to ensure you are taken care of after installation, the new AccuAdjust provides customers with an adjustable anvil that is both easy-to-use and extremely accurate, according to the company.

In addition, since each AccuAdjust unit comes plug-and-play ready for RotoMetric’s upcoming RotoAdjust automation system for greater operator control, enhanced productivity, and Industry 4.0 analytics to run smarter, customers can be confident in future-proofing their investment with a product that can easily adopt further automation when they are ready says the company.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.