Rotometal adds sustainable and antistatic sleeves

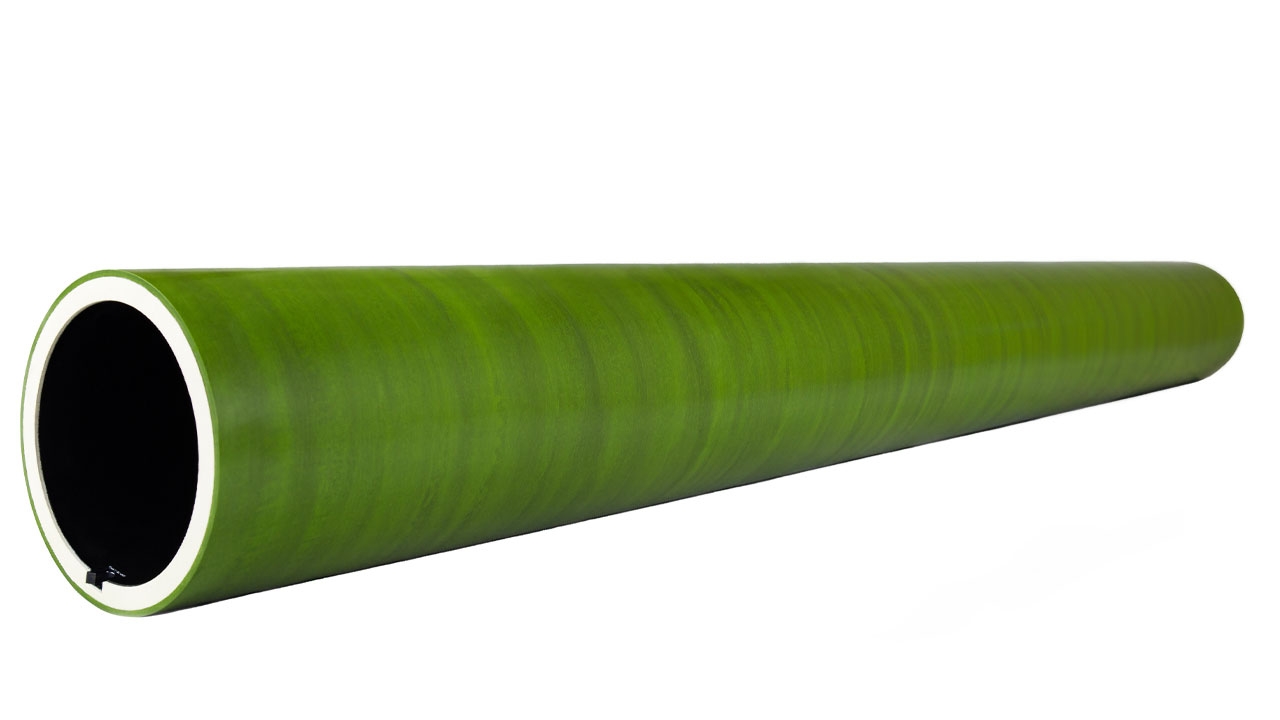

ECO CRO Sleeves GF Antistatic Print Cylinders launched for wide and narrow web flexo printing

Rotometal has introduced environmentally friendly and antistatic ECO CRO Sleeves GF Antistatic Print Cylinders for flexographic printing technology. The print cylinders combine the benefits of two products, the ECO CRO Sleeves GF and the CRO Sleeves GF Antistatic.

The ECO CRO Sleeves GF Antistatic Print Cylinders feature a honeycomb volume layer made from 100 percent recycled PET and a green-epoxy resin base layer with 28 percent of its molecular structure derived from plant origin. This eco-friendly construction maintains the strength, durability, and light weight of Rotometal's existing CRO Sleeves GF.

Customizable to customers’ machinery, these print cylinders are made-to-order.

Designed for use with solvent-based paints, the ECO CRO Sleeves GF Antistatic Print Cylinders incorporate carbon materials for charge dissipation and reduced surface resistance. This ensures safe production by discharging static charges generated during printing. The cylinders feature surface conductivity values of <10^5 Ohm and cross conductivity values of <10^6 Ohm, making them moisture-resistant and ideal for working with special paints.

Additional advantages include longitudinal and transverse guide lines for easy assembly of materials.

ECO CRO Sleeves GF Antistatic Print Cylinders are designed for use in both wide-web and narrow-web machines.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.