Schreiner develops label preserving component markings

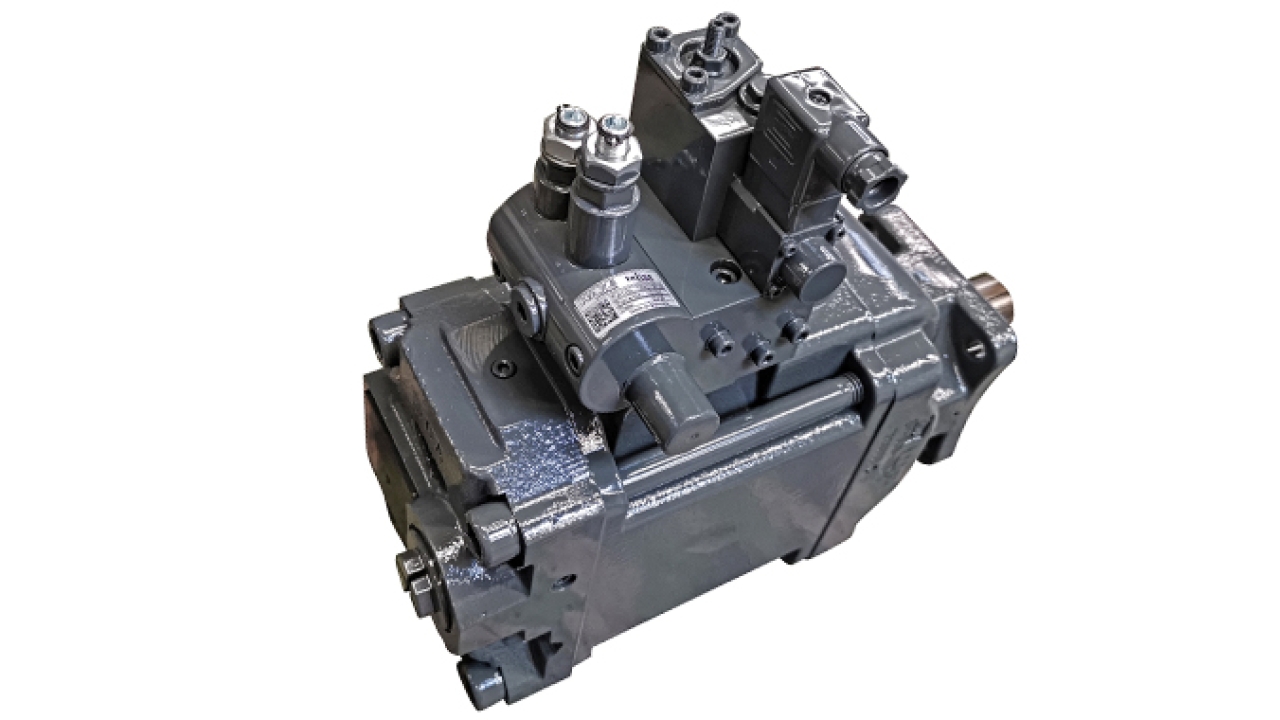

Schreiner ProTech has developed a label with a paint mask attachment that protects the inscriptions of marked components during painting, recently adapted by InLine Hydraulik for preserving the readability of markings applied to regulators and hydraulic pumps.

Previously, InLine Hydraulik had utilized metal nameplates to mark components at the end of the production process – a limitation that precluded the automated integration of digital information for storage or traceability purposes.

Now, the new folding paint mask labels from Schreiner ProTech are imprinted with 2D codes on-site, then manually applied to pumps and regulators early in the production process. After painting, the paint mask is peeled off, with the code’s readability reliably preserved. As a result, InLine Hydraulik was able to introduce 2D code marking for an optimized manufacturing process and automated traceability.

Schreiner ProTech’s paint mask technology additionally offers an option of combining a removable paint mask label with durable overlamination that permanently protects underlying nameplates against mechanical stress.

After the paint drying process, the protective label is peeled off using a starter tab; this ensures easy handling even when working with gloves. The paint mask itself is slightly smaller than the marking label, which helps the label remain embedded in the paint after removal of the paint mask film for permanent marking protection.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.