Tilia Labs releases Phoenix version 8.0

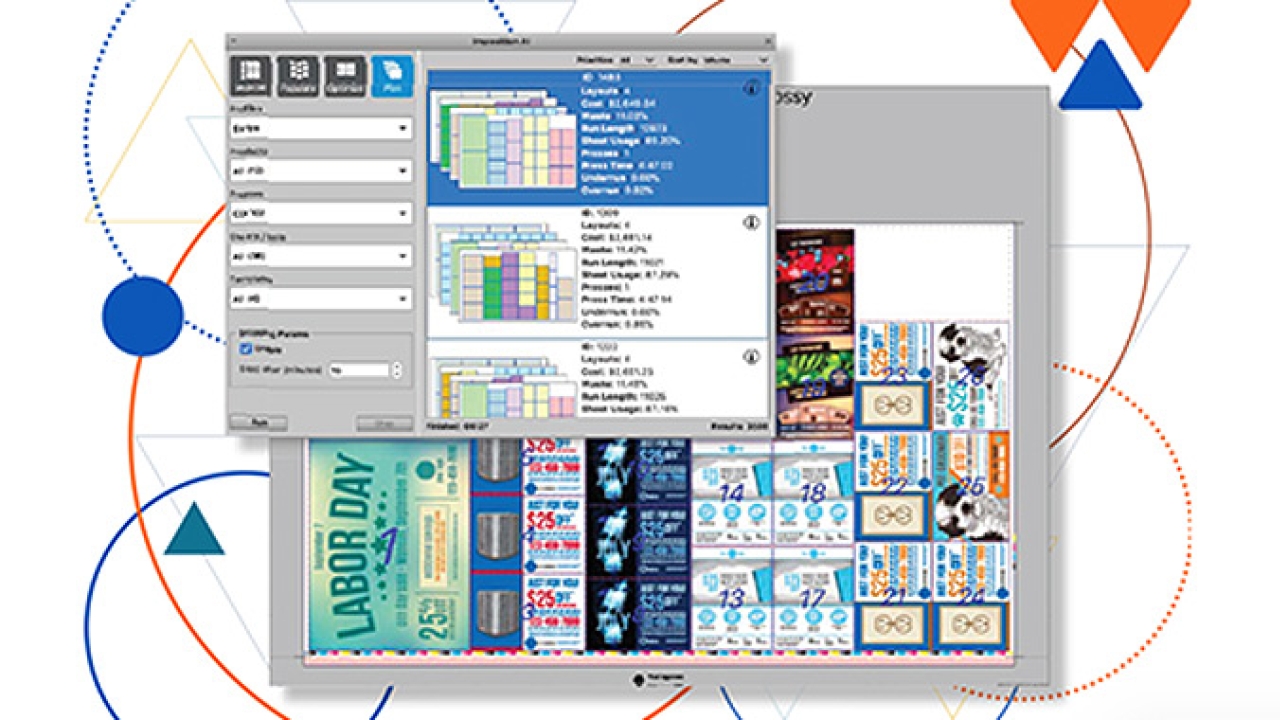

Tilia Labs has released Phoenix version 8.0, an AI-driven planning and imposition system, developed for all print sectors, including packaging and labels, offering improved print job efficiency, production, and profitability.

Supported by customer requests and industry feedback, tilia Phoenix version 8 includes new features and enhanced functionality designed to advance the user experience, accelerate productivity, provide new levels of connectivity, and introduce the software into new markets.

‘The ability to fully leverage automation is critical to competing in today’s print industry. And few, if any, technologies have accelerated time, production, and cost savings like artificial intelligence,’ commented Scott More, chief technology officer at Tilia Labs.

In version 8, API functionality is further extended for even tighter integrations. Users will have access to our quick start portal for online API documentation. The company open-sourced its Enfocus Switch connector tool allowing customers to use it freely and contribute to.

Imposition AI tools have been further optimized to automatically generate Work-and-Turn and Work-and-Tumble layouts with correct costing to compare against standard double-sided operations for sheetfed offset presses. Automating the process slashes changeover time and related labor costs.

A new PDF rendering engine provides users with separation previews. Ink visibility can be turned on/off to give an accurate view of separation, speed up jobs and reduce errors.

‘Highly accurate print and material consumption forecasting is nothing new to our customers. But with version 8, we’re taking this to a whole new level. Powered by an even more sophisticated and faster AI engine, tilia Phoenix advances automation to streamline pre-press operations, more accurately estimate jobs, including ink costs, evaluate the best printer and finishing options, and slash material waste, all while gaining efficiencies. The results are breakthrough levels of optimization and productivity that are reflected in the bottom line,’ added More.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.