UPM Specialty Papers introduces new heat sealable and recyclable papers

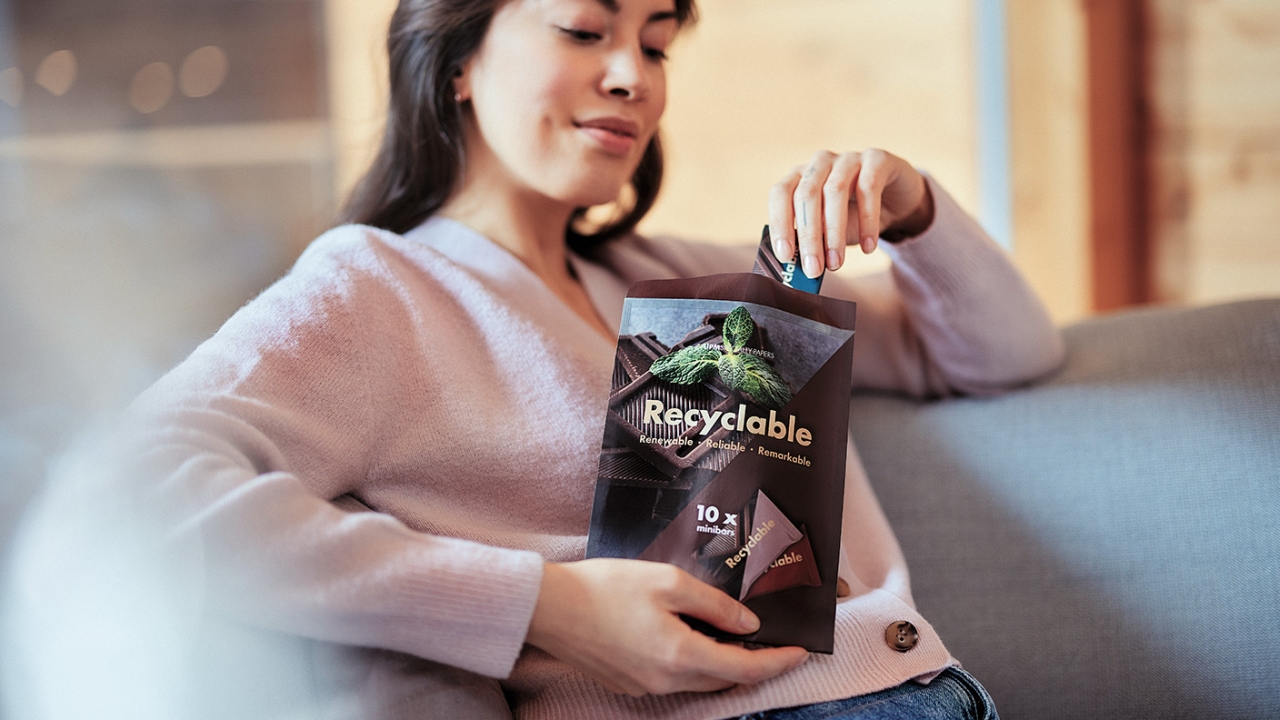

UPM Specialty Papers has expanded its selection of sustainable and recyclable packaging papers with UPM Confidio and UPM Confidio Pro combining moisture, and grease resistance with heat sealing properties.

The heat sealability allows for a streamlined conversion process and an accelerated time-to-market. Made from renewable fibers, UPM Confidio and UPM Confidio Pro are repulpable and designed to be recycled in regular fibre recycling streams.

In addition, UPM Confidio Pro offers improved print results through all printing methods, with saturated, sharper and more vivid colors. The combination of heat sealability, moisture resistance, grease resistance, and a mineral oil barrier makes it a suitable choice for a wide range of end-uses.

'Our goal is to replace conventional fossil-based packaging and increase the share of renewable packaging solutions. With features supporting both primary and secondary packaging, UPM Confidio and UPM Confidio Pro are recyclable, cost-effective and safe to use. The products offer excellent convertability and enable a visual look which makes brands stand out on the shelf. By combining all these elements, the UPM Confidio line of exciting packaging products are almost too good to be true,' said Tommi Heinonen, head of sales for EMEA at UPM Specialty Papers.

UPM Confidio and UPM Confidio Pro are suitable as both primary and secondary packaging for dry, greasy, and frozen food products. They are FDA and BfR compliant and safe for direct food contact.

'Heat sealability was a top priority for our stakeholders and our goal was to provide them with high-quality, recyclable solutions. Developing our R&D functions even further and creating these cutting-edge packaging products has been a significant investment for us. A novel packaging process and improved analytical capabilities at the UPM Research Center enable us to test product features, create samples, and complete prototype phases,' said Janne Varvemaa, director of products and technology at UPM Specialty Papers.

According to UPM Raflatac, the packaging industry is experiencing an unprecedented change with greener, easily consumed goods, and easily recyclable packaging demanded by consumers and changing regulations. These factors impact the entire packaging value network. UPM Confidio and UPM Confidio Pro have been developed strongly based on feedback from UPM Specialty Papers’ partners. During the product development process, UPM Specialty Papers has expanded its co-operation with external partners such as the leading Finnish food and bakery company Fazer.

'At Fazer, we take great care to craft high-quality food with sustainability in mind. That’s why we expect the same quality from packaging material. We have thoroughly tested UPM Confidio and made it work well after some line trials with machine changes and adjustments. We have been impressed with how well it protects, maintaining the food product high-quality until it’s best before date. It is high-quality and easy to use in packaging processes but accomplishes all of this with less fossil-based materials. Reducing fossil-based material waste is important to both the Fazer team and to so many consumers. We can’t wait to see UPM Confidio packaged Fazer Oatly Rice pie products on store shelves soon', described Piia Soininen-Tengvall, director of packaging development at Fazer Group.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.