Wink launches ProMount system

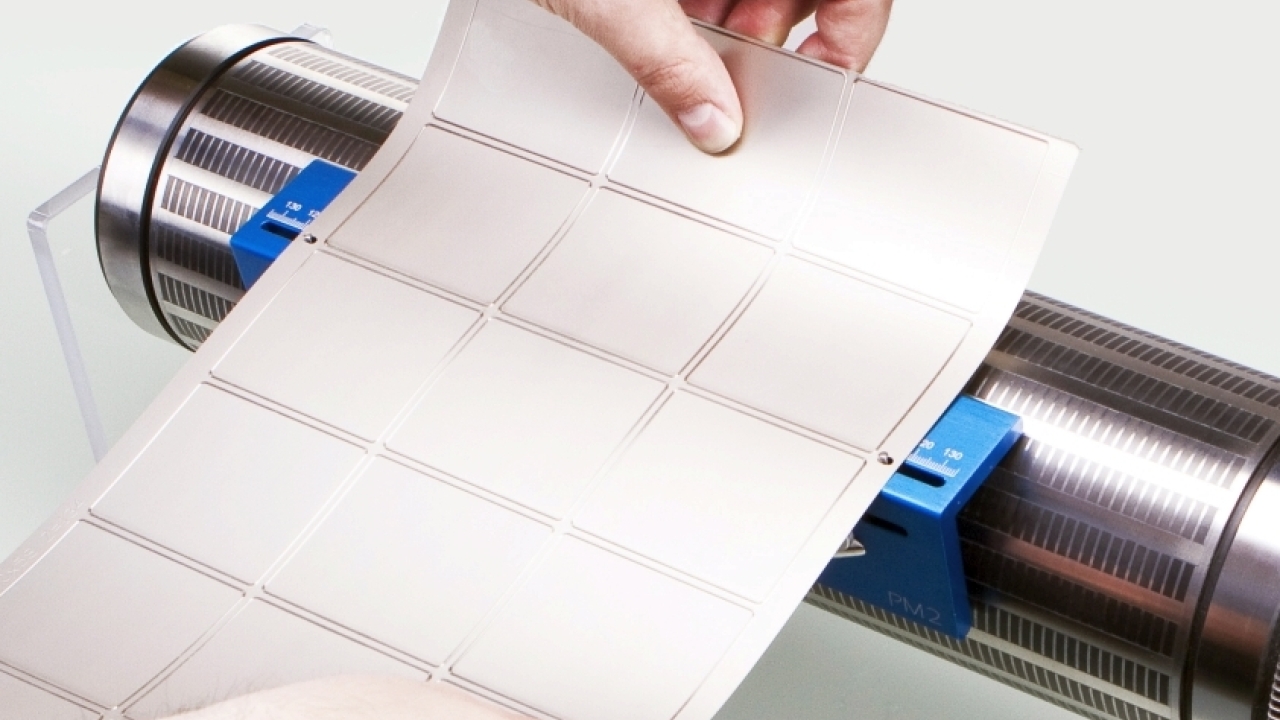

Wink has launched its ProMount aligning tool for flexible dies. The ProMount aligning ruler is available for all common narrow web machines and facilitates the mounting process enabling dies to be perfectly aligned on the magnetic cylinder.

The system is said to provide more comfort and safety for the operator during retooling processes and help optimize die-cutting results as well as save time and money.

The company said, ‘With this tool, the perfect installation of flexible dies is made easily and quickly. The tool not only makes job changes more convenient, it also results in increased productivity and cost savings. The very compact and yet robust design guarantees a high lifetime of the ProMount ruler.’

ProMount is available in seven standard types (PM 1 to 7), with each type optimized for specific machine types and working widths. Each type is best suited for cylinder circumferences from 65 to 204 teeth (1/8’’ cp), so that a broad range of applications is covered. Special individual sizes can be produced on request.

The tool is designed to make positioning of flexible dies easy by automatically aligning parallel to the magnetic cylinder surface. By the use of a small extra tool, the tool is adjusted on the cylinder so that the flexible die edges will be placed in the center of a magnetic row. ProMount flexible dies are produced with special fitting holes which are used the fix the die on the ProMount ruler. After placing the upper part of the die onto the cylinder, the ruler can easily be removed by pressing a push button. The remaining part of the flexible die is then placed on the cylinder and fits perfectly.

Pictured: The new ProMount system from Wink

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.