Xsys streamlines flexo plate processing with new Catena-BE 48

By automating plate transfer between imager and exposure unit, the ThermoFlexX Catena-BE 48 eliminates operator intervention and optimizes efficiency.

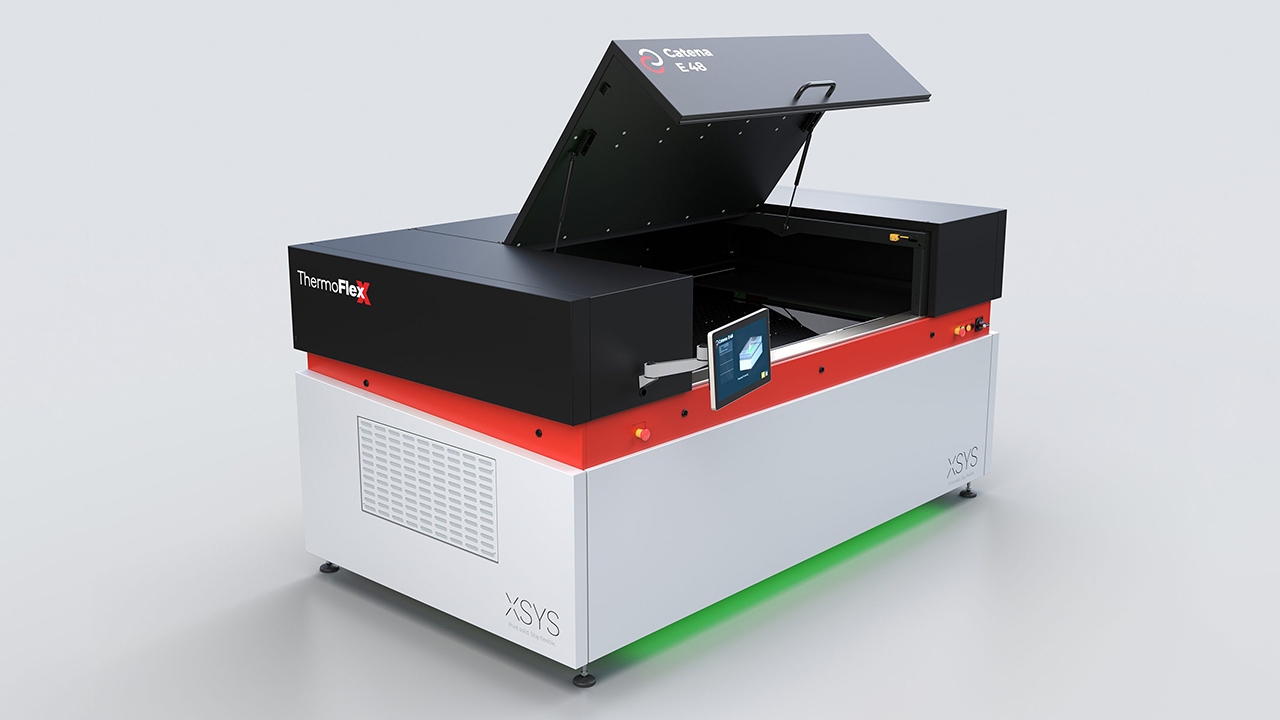

Xsys has launched ThermoFlexX Catena-BE 48, latest innovation designed to increase efficiency and decrease waste in flexographic platemaking by automating plate transfer between imager and exposure unit.

The Catena-BE48, incorporating both hardware and software components, allows an integration with the ThermoFlexX TFxX 48 Imager, facilitated by a bridge, creating an efficient, and touch free workflow. Catena-BE 48 employs a precision gripping system which ensures zero waste of plate material during transport.

With this innovative method, the TFxX 48 Imager can be pre-loaded and prepared for the next job while the previous plate is transferred autonomously to the Catena-E 48 LED exposure unit. This automation saves time and guarantees that job presets are maintained throughout the process, ensuring that there are no configuration errors, to prevent waste and enhance efficiency.

‘The objective for the development of the Catena-BE 48 was to provide another automated solution that allows platemakers to take out manual steps in the process and thereby accelerate plate production,’ said Bert Eeckhout, product manager for Xsys PrePress.

‘Reducing operator handling of plates minimizes the risk of accidental damage or misplacement and therefor prevents waste. As automation takes over manual and repetitive tasks, operators can dedicate more time to other important aspects of the production process, aligning with lean manufacturing principles,’ added Eeckhout.

Customers currently using a ThermoFlexX TFxX 48 can improve their capabilities by upgrading from a standalone imager to an automated imaging and exposing line by adding a Catena-BE48. According to Xsys, this upgrade not only enhances efficiency but also significantly boosts competitiveness.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.