Non-contact cleaner launched

Meech has developed its first non-contact web cleaning system specifically for the narrow web industry, as Andy Thomas reports

Meech International is to launch a non-contact web cleaning system at Labelexpo Americas developed with the help of a sophisticated modeling and prototyping process.

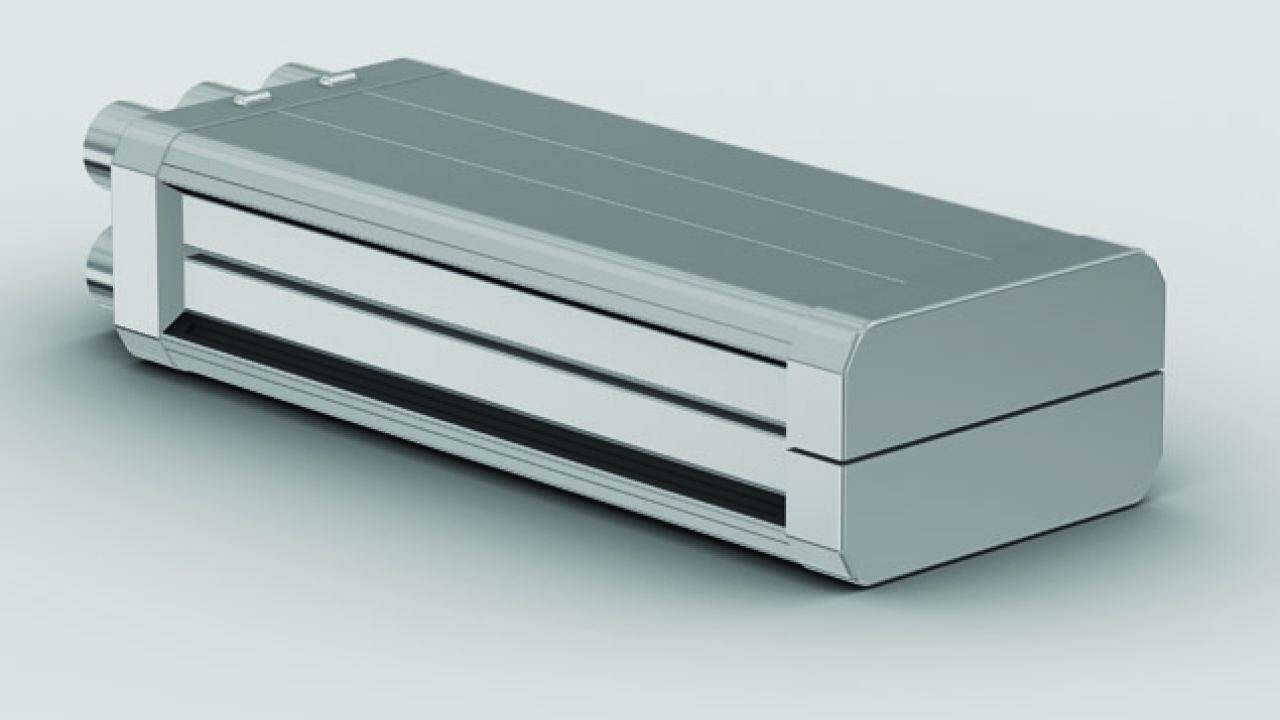

CyClean is a double side blow and vacuum-based web cleaning system which flows contaminants into an in-line filter unit. It is Meech’s first non-contact system developed specifically for the narrow web industry.

‘Compared to our existing non-contact system this is priced and targeted more at the narrow to mid-web web sector,’ says Adam Battrick, business unit director, Cleaning Systems at Meech. ‘In the future we plan to roll out a unit for over 1 meter web widths.’

The CyClean unit has been designed with a small footprint so it can be fitted into a confined space without having to extend the web path. A cantilever mount allows easier access to web up where space is tight. It is available both as an OEM unit and for retrofits.

Design challenge

‘In developing CyClean our two main challenges were how to remove very small levels of particles, and to eliminate the need for operator adjustment,’ explains Battrick.

Automatic monitoring was achieved by increasing the fan performance as the filter gets progressively blocked so that the preset performance levels are maintained. When the filter needs changing, interlocks and operator warnings kick in.

Removing small particles required an in-depth knowledge of airflows over the web and inside the cleaning system itself. This is where a combination of computational fluid dynamic modeling and rapid prototyping came into play.

‘Just a few years ago this technology would not have been available to a company of this size and the whole development process would have taken at least three times longer,’ says Battrick.

The project was carried out in conjunction with a renowned fluid dynamics consultancy which modelled airflows over the web and through the unit. Airflow on a moving web not only creates turbulence in the machine direction, but also across the web, leading to a set of highly complex, dynamic changes which can cause web ‘flutter’ and vibration. The challenge is to ensure even blow and vacuum airflows across the web.

The fluid modeling information was used to design new 3D parts on Meech’s CAD system, with the resulting files sent electronically to the rapid prototyping supplier. The plastic part was delivered within two days for assembly into the next prototype.

‘We were able to use the physical part to prove that the modeling was accurate,’ says Battrick. ‘We could model factors like shear stress across the web at different production speeds and with different materials so we could understand how much force was needed to move particles of different sizes. We had a mountain of research which we could apply directly to the design, prototyping and manufacturing process.'

As an example, the modeling prototyping sequence quickly showed up problems with an early design where contaminant exited the unit with the web. ‘So we had to modify the air flow to keep the contaminants within the unit, which itself affected airflow on the web,’ says Battrick.

Labelexpo Americas

At Labelexpo Americas Meech continues its move to address the label market with the launch of a static bar designed specifically for narrow web presses.

Meech also shows its TakClean contact web cleaner for the first time in Chicago, capable of operating speeds up to 250 m/min, and a ‘maintenance friendly’ redesign of the VacClean contact cleaner. By allowing the faceplate to slide easily off the manifold body, converters can save up to two hours downtime, says Meech. The manifold has been redesigned for more even web coverage, so fewer duct connections are needed and single length manifolds of up to four meters can be used.

Pictured: CC Chrome, a rendered image of the final CyClean design

This article was published in L&L issue 4, 2012

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.