Polish growth supports investment

The continued success of Poland’s economy has encouraged converter KDS to invest in a new Mark Andy P5 and Rotoflex inspection rewinder. Andy Thomas reports

‘We anticipate the new Mark Andy P5 will boost our efficiency by 35-40 percent,’ says Tomasz Dabrowski, owner of KDS, the label converter based in Sulejowek in Poland. His confident prediction was made after visiting another Mark Andy P5 user, Labelprint in Estonia.

In three years, this small label converting business has equipped itself with two new flexo presses, and importantly, according to Dabrowski, two Rotoflex inspection/rewind machines, which have immediately overcome a production problem KDS had been incurring with tension control.

‘We installed the first Rotoflex VSI in 2010 after looking around the market for a machine that suited our type of work. It was the Rotoflex’s a/c vector motor that clinched the deal. The machine’s servo drive allows us to run with very low tension, and this prevents the perforations from tearing on the tickets we produce.’

A second machine was installed in 2011 – this time a Rotoflex VSI with the latest Genesis control system. The new software adds greater control and the ability to store job information for future recall. Dabrowski is proud that he had the first of the new Genesis machines to be installed in Europe and claims that it offers a complete job change in 30 minutes. With plans afoot to invest in MIS to provide better production data, the Genesis software on the Rotoflex is a key link in improving efficiency at KDS.

With business growing at around 12 percent year on year, there became an obvious need to increase print capacity, and following negotiations with Mark Andy’s European office, and distributor in Poland, Digiprint, a deal was struck to install a rather special P5 press. Specified and built as an exhibition demonstration model for Labelexpo India

and Labelexpo Europe, the 6-color P5, fitted with UV curing and chill rolls, is a perfect fit for KDS’ short run work. A laminating unit is on order for installation, but otherwise the press went straight into production the weekend it was delivered to work alongside its 10” stablemate, the 2200, with full interchangeability of print cylinders and anilox rolls.

According to Dabrowski: ‘The servo drive gives remarkable registration accuracy. We make ready on plain paper and then splice the correct substrate for the job. Waste is only 25-30 meters per make ready because the web path from unwind to rewind is less than 12 meters.’ So good is the registration, that KDS has been able to process 12-color jobs without difficulty by re-passing the printed web through the press. ‘Irrespective of speed, the register is always spot on,’ he adds, saying: ‘we regularly run the P5 at 200 meters/minute.’

Fitted with low volume ink trays with Teflon coating, the P5 is fast to wash up. This is ideal for KDS’ work, which typically is 500-2000 linear meters, and mostly 4-color process plus varnish, or four process, one special and a varnish. It is work that Dabrowski sees as well suited to the P5 flexo line.

‘I do not see digital as an industrial process yet – it has too many variations in its technology. For short runs, especially on expensive substrates, the P5 still performs better,’ explains Dabrowski.

Currently, KDS’ business is split 35 percent filmic: 65 percent paper substrates, with the former continuing to grow. Markets served are mostly the food industry, where KDS has seen demand pick up in the recession, with more food being purchased for home consumption. The company is also moving into peel-off labels and has been experimenting with different weights of varnish to lower the power of the adhesive, to make for easier peeling. In addition, the Mark Andy 2200 press is fitted with the company’s Gizmo unit for peel off labels production, which is an area KDS is keen to develop.

Most recently, KDS has installed an EskoArtwork CDI platemaker with HD module that offers 4000 dpi. The Mark Andy P5 is approved by Esko for HD flexo production, which allows KDS to offer very high quality on low quantities, at competitive prices. ‘I see this as a good sales tool, and as an insurance against rampant price cutting,’ says Dabrowski.

Looking ahead, he sees growth in multi-page booklet work, and Braille printing on lightweight cartons, for which he will add a screen cassette unit. The company currently produces cinema and transit tickets on 250-gsm card, and it intends to grow this sector of business, along with its export trade, which is currently small. In its second factory, KDS manufactures plain labels and thermal transfer ribbons for barcode printers. A staff of 70 generated a four million euro turnover in 2011, but Dabrowski is keen not to grow too large, believing the flexibility of a smaller unit offers better security against market fluctuation.

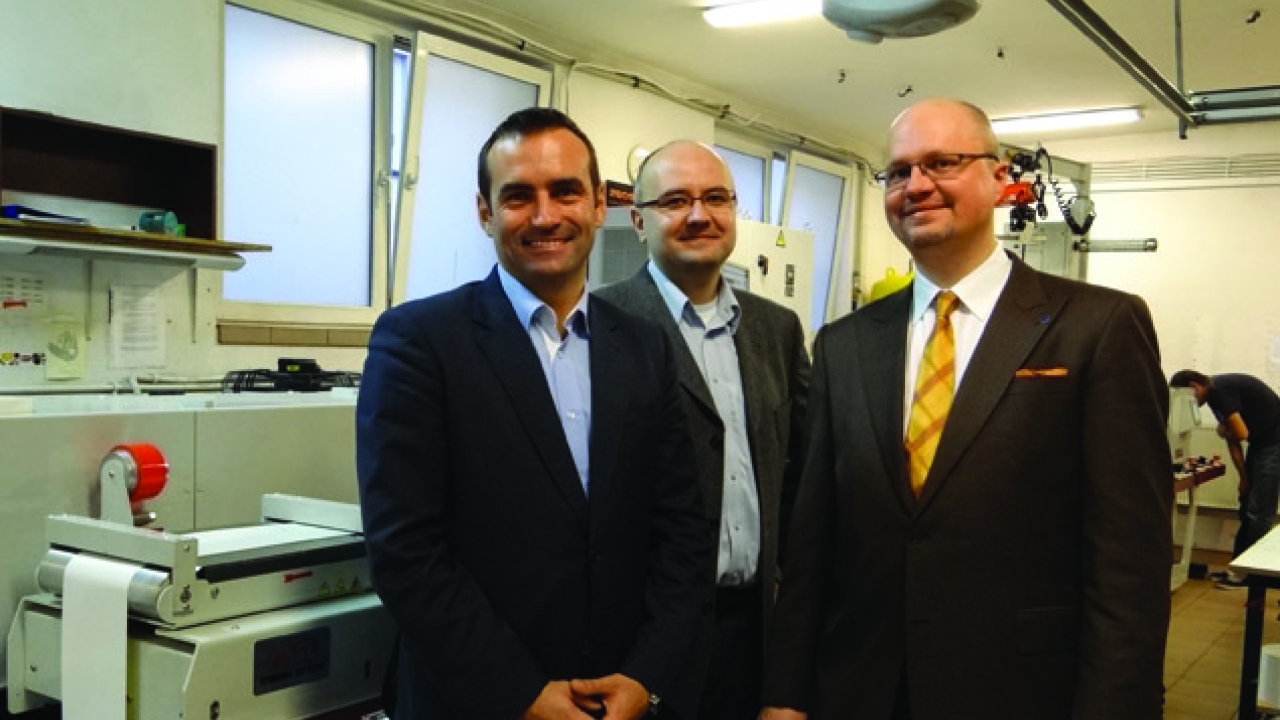

Pictured: (L-R) Tom Cavalco of Mark Andy and Przemyslaw of DigiPrint, with Tomasz Dabrowski, whose new Mark Andy P5 flexo line will boost efficiency at KDS by up to 40 percent

This article was published in L&L issue 2, 2012.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.