Space to grow

Despite a tough economic climate, converter Pilot Italia is making big changes to accommodate future growth. Carol Houghton reports

Leading Italian converter Pilot Italia is seeking new opportunities for growth with the opening of a new factory and the establishment of a network of like-minded European converters.

The new plant at Cornate D'Adda, near Milan, was commissioned in November 2011. The site covers an area of 20,000 square meters. As yet only 7,500 square meters has been built upon, leaving plenty of space for expansion.

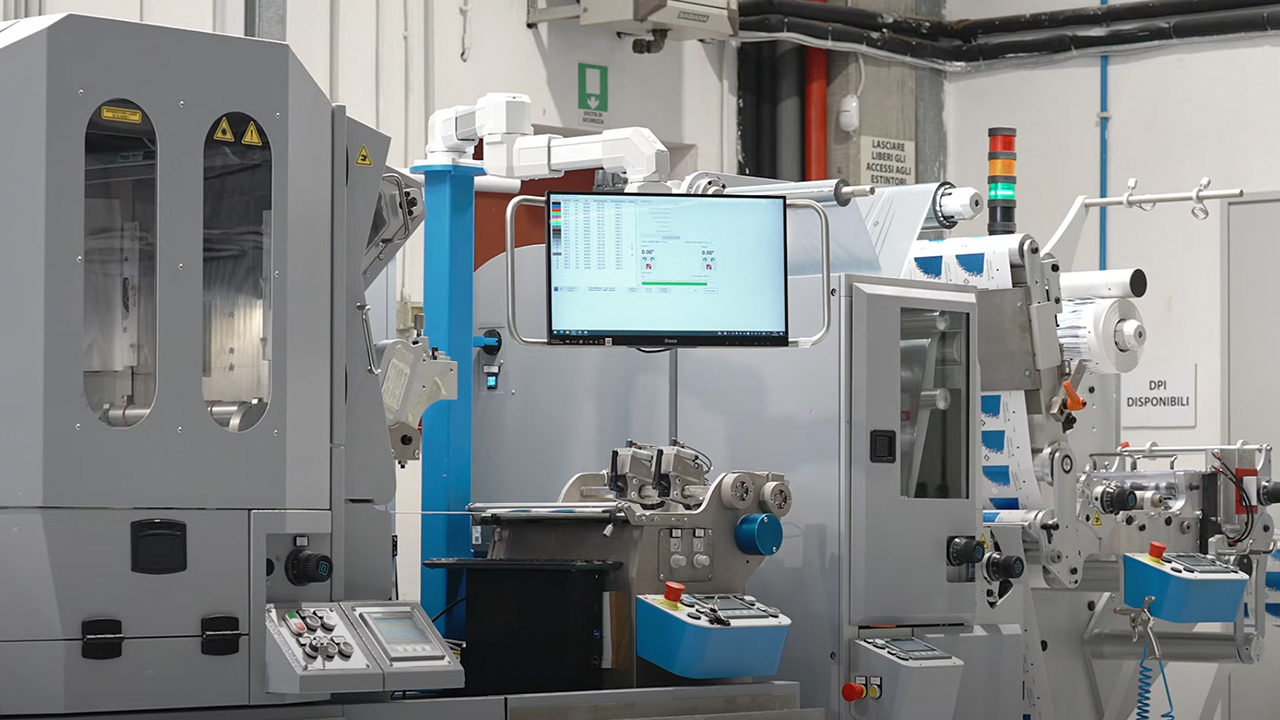

Pilot works mainly in combination printing on 11 presses; two Nilpeter MO 3300, two Drent 520 Offset, five Gallus (silk and letter press combination), one Arsoma and one Codimag waterless offset. During the five week move into the new factory, production was kept running. ‘The customers had no idea and we experienced zero losses in production,’ says Pilot Italia sales manager and ex-Finat president Andrea Vimercati. The second plant in Usmate is still in use for pharmaceutical work.

The new plant was specifically designed to take advantage of Kaizen, a Japanese principle which translates into ‘continuous improvement’. Under the concept, printing and finishing at the new facility is done on the same floor. Vimercati explains, ‘We started with Kaizen as business was becoming too expensive and we were losing work to competitors. The idea came from my travelling in Japan. Now we offer a better price and quality while maintaining margin.’

The company has invested heavily into sustainability. For example, an extraction system takes matrix waste from each production line, to be compacted and sent on to an incineration plant to create energy. These activities are in line with TLMI’s Label Initiative for the Environment (LIFE) program.

The company is also working with its suppliers to replace a three week warehouse inventory with just-in-time delivery.

Changing for the future

Pilot Italia specializes in a wide range of end user sectors including pharmaceuticals, home and personal care, industrial, cosmetic, beverage and food industries.

Before the recession, the company had an annual growth rate of seven percent, but turnover has been flat in the last five years. ‘The new plant will help business to grow,’ says Vimercati. He expects the facility to open up new business opportunities such as security labels, which ‘were too complicated to introduce in the old plant’. Specific areas within the new plant have been designed for temperature and humidity control and have special hygiene measures for food labeling.

In addition to labels, Pilot Italia prints film and occasionally flexible packaging. It does not yet print cartons, although this is an option for the future. We market ourselves as having “label and packaging knowhow”,’ Vimercati explains. ‘When we go to customers we want to give them the best total solution; to understand more than just the printed label.’

He believes too many printers ‘just take the order’. Pilot Italia prefers to ask why the order is being placed to evaluate whether that the best option has been selected, or whether a more suitable alternative can be suggested.

Competitors and partners

Pilot Italia has recently set up a partnership with Schaeffer Etiketten, in Stuttgart, Germany – a similar sized company, sharing its market vision and using similar machines. Vimercati explains, ‘We wanted a partner to offer insurance so we can keep printing by off-loading work, in compliance with a disaster recovery policy. It also works for exchanging technology and ideas.’

For Vimercati, the next step is to increase collaboration and work on a new partnership with Germark, a Spanish company based in Barcelona. His vision is to build a truly international network.

Another interesting partnership has been established with three Italian printers; Notarianni, Aro Etichette and Mida Etichette. The idea is to offer each other complimentary production and technology. Vimercati suggests one example, ‘We don’t do digital but the other three have HP machines so we can use their machines if a job requires’.

Vimercati explains, ‘The network is an additional offering to the customer. It will be used for a creative purpose but also act as a purchasing group.’ It is all about relationship building and he hopes it will help each individual company to grow with its partners. Together the group has a turnover of 50 million euros and is currently discussing a network name and logo to help bring the offering to customers and explain what it is doing.

Alfredo Pollici, CEO of Notarianni, gives his reason for joining the partnership, ‘Andrea is a good friend but it also provides good R&D opportunities for us.’

Vimercati concludes, ‘The world is changing the way in which business is done, Buyers are changing and new, younger work forces are using more technology and social media.’ A reflection of this can be seen in the recently updated logo to create the image of a ‘younger, faster, modern company’.

History

A branch of the international company Pilot, Pilot Italia began manufacturing customized, self-adhesive labels in 1968. It became a Joint-Stock company in 1984, serving the European pharmaceutical, cosmetic and food industries. The company’s French activities closed in the 1990’s with the plants passing into the ownership of by Avery Dennison.

Pilot has 90 employees, running two eight hour shifts. Exports account for 10 percent of the business, and a growing sector is multi-language labels for global brands which export out of Italy. The company makes its own plates and screens.

Investment

In July 2011, Pilot Italia increased its production capacity with the purchase of a Muller Martini VSOP 520mm web width offset line and a matching Prati Vegaplus LF530 finishing system. Of the Vegaplus, Andrea Vimercati says, ‘We have been particularly impressed by the processing speed of this machine, a feature which is essential to keep up with the speed of the offset press. But there is another feature that makes it unique and innovative: the modular construction of the machine, which allows the addition of die-cutting, an inkjet system for numbering labels or flexo printing heads.’

The Vegaplus LF530 system incorporates a 100 percent inspection camera control system and is specified to handle a wide range of materials including paper labels, foils, self-adhesive labels, and single or multiple component flexible packaging materials.

Pictured: Pilot Italia’s new site covers an area of 20,000 square meters

This article was published in L&L issue 5, 2012

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.