Vigilance uncovers forgery

In what is being described as a ‘triumph for common sense’, three British companies have reached a landmark agreement to thwart the growing threat of counterfeiting from Asia. The companies involved are the manufacturer, Item Products, the supplier, Trendsetter, and major international brand owner, Habitat.

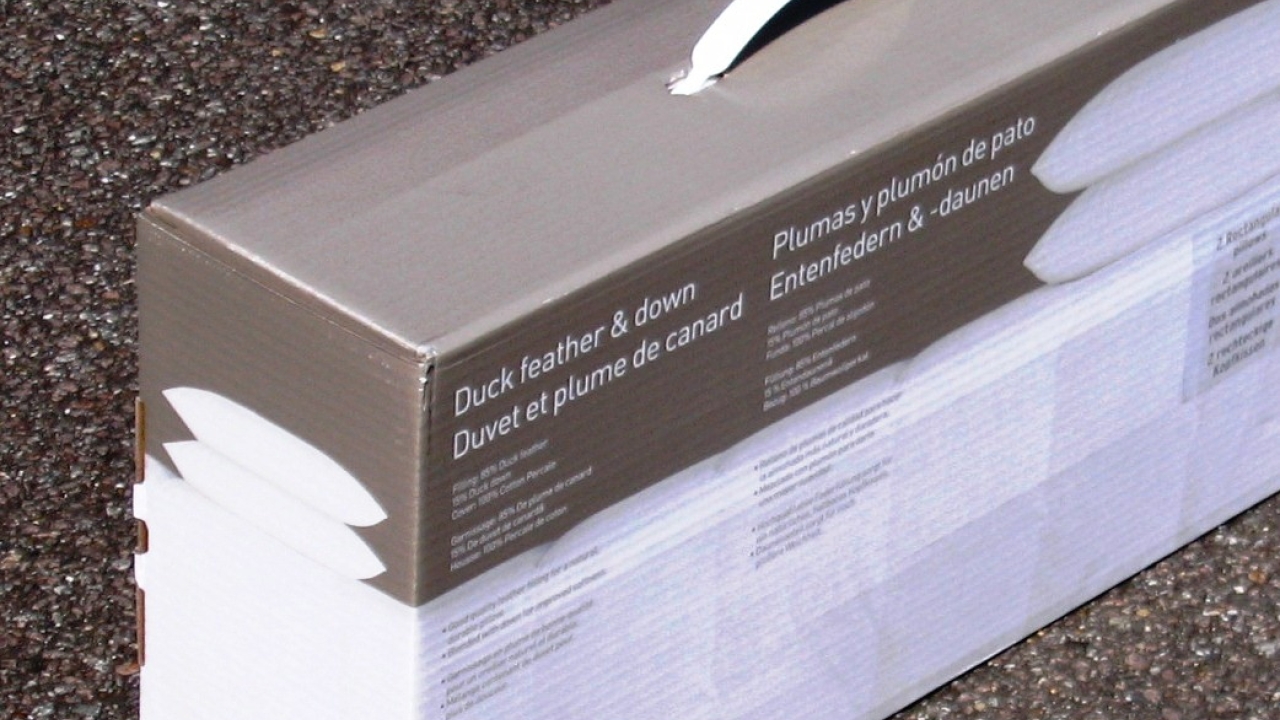

The problem arose when Item Products, which supplies injection moulded handles to Trendsetter for the packaging of a range of pillows and duvets sold by Habitat, identified a batch of fakes during routine in-store spot checks. Julian Cook, managing Director at Item, explained: ‘Item goes to great lengths to protect its designs with European Patents or Registered Community Designs, and will take all measures necessary to defend them.’

The company invests a great deal of time and money in ensuring its products are fit for purpose, and that the material type and grade suit the application. ‘What shocked us most of all was that the fake was so near to perfect in the way it was copied that only engineering points and inferior grade material gave the game away. Aside from the loss of revenue, one of the major issues with forgeries is that whilst they might look identical, if the forger has used an inferior grade of material and the product fails, the perception of poor quality falls back on the original manufacturer.’

Item Products immediately alerted Trendsetter, which supplies and packages the pillows and duvets for Habitat, of the problem that had apparently arisen when sourcing was switched from Europe to Asia. Trendsetter contacted Habitat to explain the situation and an agreement was reached that while no further handles would be sourced from Asia, the cost and inconvenience of withdrawing all fake handles from Habitat stores and replacing with authentic ‘Brandles’, would be counter-productive.

Explaining his company’s business philosophy, Cook commented: ‘We believe in ‘brand UK’ and work hard to ensure that we compete effectively with overseas competition.’ Much of the work that was moved to China over the past decade on cost grounds is now returning to this country as run lengths shorten, stockholding reduces, and JIT deliveries become the norm. ‘Item offers flexibility and superior quality that is more than a match for the lower prices and extended freight times and shipping costs associated with manufacturing in Asia,’ he concluded.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.