Edelmann Group invests in EyeC Proofiler Graphic

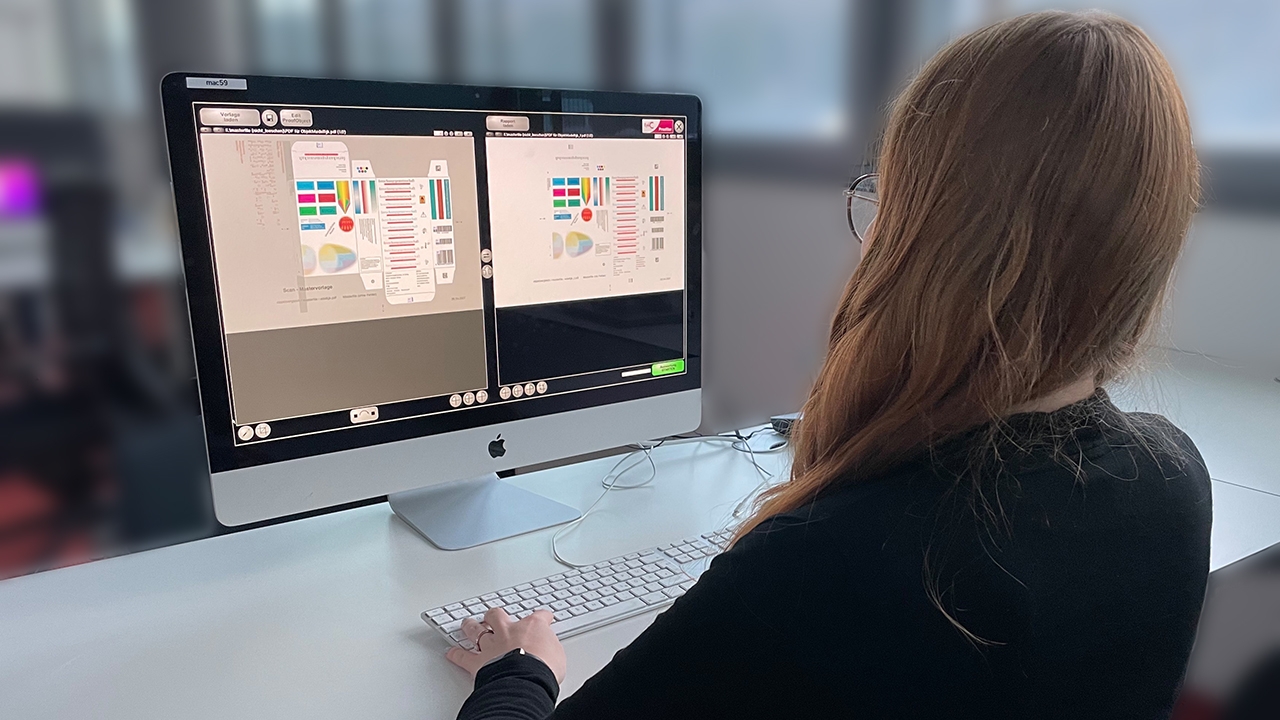

Germany-headquartered packaging specialist Edelmann Group has invested in the EyeC Proofiler Graphic pre-press inspection system to optimize its efficiency further, automate the inspection process and achieve 100 percent accuracy.

The Edelmann Group designs and produces high-quality, sustainable and individual packaging made of cardboard and paper for products for health care, beauty care products and consumer brands. The family-operated company, founded in 1913, now has a global presence with locations in Germany, Mexico, Brazil, Hungary, Poland, India and China.

The group already used an automated inspection system to ensure the quality of its products in the pre-press control process. With the EyeC Proofiler Graphic, the quality of the print templates could be further optimized.

To continually improve the inspection process, identify sources of error and guarantee reliable quality control processes, the Edelmann Group uses the EyeC Proofiler Graphic to automate the inspection process further and guarantee 100 percent accuracy.

‘It was crucial for us to find an inspection solution that not only ensures accuracy but also suits the people operating the system,’ said Marcus Czogalla, head of pre-press and CTP department at Edelmann. ‘We’ve been working successfully with EyeC for many years and have once again been convinced that it is the best possible option for us.’

The EyeC Proofiler Graphic automatically compares the entire content of print-ready files or step-and-repeat files with an authorized print template. Unlike the human eye, the system detects every error within the print-ready PDF files.

All kinds of deviations can be discovered before the printing plates are manufactured. Texts, graphics, Braille, as well as 1D and 2D codes are checked graphically in just one inspection run.

‘We were particularly impressed by the user-friendliness and easy handling of the system, as well as the numerous tools and setting options,’ added Czogalla.

Czogalla also names the reliable support of EyeC’s service department as a decision factor: ‘The quality of EyeC’s team is unique. Our contacts are knowledgeable, responsive and – just like the Edelmann Group –always approach things individually without losing sight of the big picture.’

Through the implementation of the EyeC system, not only could the data processing process be made more efficient, but the risk of graphical deviations was also further reduced. Waste and recalls can thus be effectively avoided, and the security of data and processes can be significantly increased.

‘An additional testing instance in the pre-press department is not necessary with the EyeC Proofiler Graphic, which enables the production data to be processed even faster, added Czogalla. ‘The testing process is not only fast and reliable but also reproducible and offers us the opportunity to fully monitor our workflow to increase efficiency.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.