Adding value with connected packaging

Consumer product packaging has long been scrutinized for structural and aesthetic performance. Now, though, a more important characteristic is at the fore – intelligence.

Packaging can be smarter and ‘digitally connected’ when combined with distributed computer systems and the web. This change will revolutionize productivity and quality while delivering new capability in a variety of product packaging applications. This capability has led to the fourth Industrial Revolution for manufacturing, or Industry 4.0, where data is dominant, and the Internet of Things (IoT) provides greater connectivity than ever before.

Packaging took a technological leap forward in the mid-1970s when it began carrying a printed UPC barcode that provided automatic price scanning at retail checkout – a foundational moment when new symbols on packaging, combined with sensor technology and computing power, provided a digital link to point-of-sale systems. In the 1980s, manufacturers discovered the power of 2D barcodes and machine vision to automatically identify objects to match with the right product or to assemble multiple packaging components.

Packaging has since seen more symbols and codes clutter its ‘real estate’, including introducing the famous ‘Mobius Loop’ symbol, to indicate the container should be recyclable. The introduction of the QR code enabled marketing professionals to leverage the proliferation of mobile devices among consumers. This was a turning point, where consumers began to engage with packaging directly, leading to further programs such as SmartLabel in 2015, which responded to consumer demand for product data. Several consumer brands also introduced custom marks for consumer engagement including Pepsi’s PepCoin and Coca-Cola’s Sip-and-Save.

For packaging and label suppliers, there are strategic use cases where converters can add value, increase competitive advantage, and assume a market leadership position with connected packaging products. Topping the list of these use cases are food safety and traceability, manufacturing productivity and quality control. Printers and packaging designers are tasked with implementing next-gen machine-readable codes leveraged for a wide range of advanced applications; now is the time for market leaders to support the value-add of connected packaging.

Food safety and traceability

Consumer safety, particularly for fresh packaged items, is a major focus of manufacturers and consumer brands. Consumer brand leaders, trade associations and governing bodies have responded, from the formation of the US Food and Drug Administration (FDA) in the 20th century to today, with the introduction of batch-lot coding to assist with consumer food safety and risk management in supply chains. The European Union made the incorporation of traceability a requirement for consumer product food businesses in 2002 under the General Food Law. Canada passed a series of consumer safety laws in 2019 that changed labeling practices on consumer prepackaged fresh fruits and vegetables. Both require information such as common name, lot code or other unique identifiers, and name and place where the food was manufactured, prepared, produced, stored, packaged or labeled to be available.

In 2018 GS1, a leader in standards that enable an ecosystem of shared data between trading partners, published its inaugural Digital Link standard with a vision to represent GS1 Identifiers within IoT platforms. Using URL lookups, this enables multiple applications without adding various new codes and mark requirements to often limited packaging space.

Most recently, the FDA published a ‘New Era of Smarter Food Safety Blueprint’, which outlines its food safety plans for the next decade. Most current systems rely on human-readable codes and paper-based records that lead to a state of ‘anonymity and lack of transparency in the food system’, the FDA wrote. Among the four foundational pillars of the Blueprint is Tech-Enabled Traceability with a vision ‘to create a more nimble, resilient, and interoperable food system’.

Manufacturing productivity and quality

According to a survey conducted by Packaging World of over 200 product manufacturers in 2019, 52 percent shut down a line once a month due to mislabeled products. In the United States alone, the average food recall will cost a company $10m USD in direct costs and perhaps another $19m in indirect costs, according to the GMA. Machine-readable codes on each package and product component can be leveraged to perform quality control within manufacturing software. Only 17 percent of respondents in the survey used machine-readable codes, while 35 percent pointed to planned investments in automated control systems.

Parts-matching and quality control are examples of how machine-readable codes add value to manufacturers of packaging and products. Growth in global supply chains and e-commerce has led to increased opportunity for counterfeit and gray-market goods to infiltrate distribution systems and make it into consumers’ hands. Illicit goods detected by US customs alone cost product manufacturers $1.4 billion in lost sales in 2018 compared with $94 million in 2003, according to the US Department of Homeland Security.

In 2021, high-speed cameras in European Material Recovery Facilities (MRFs) will begin to detect digital watermarks on packaging to improve the proper sortation of food-grade and re-usable plastics. This innovative first step was spearheaded by Procter & Gamble, and now in its second iteration, HolyGrail 2.0, which has more than 85 participating members such as PepsiCo, Colgate-Palmolive and Unilever. These leading brands have announced digital watermarking plans as next-gen sortation capability is realized in the European Union (EU) and beyond.

Product manufacturers, with leadership from their packaging suppliers, can parlay internal productivity initiatives and increased customer value by implementing digitally connected packaging. Implementation of Industry 4.0 extends across the value chain, where packaging suppliers and their supply chain can leverage digital identities to optimize existing processes and create new products.

Implementing connected packaging requires machine-readable codes, detection cameras, data distribution and end-user applications. Packaging suppliers support their customers in multiple ways, most critically with the digital identities embedded within their products, within the numerous production stages of design, prepress, printing and quality control.

For print suppliers, implementation of digital identities has primarily been in a ‘static data’ workflow, where an entire print run, or many repeat print runs, use the same input data for machinereadable codes. The implementation of variable data, such as DataMatrix batch/lot codes, often has been ‘off-line’ of package printing – implemented by industrial inkjet printers or laser marking devices at various stages of product packaging and distribution.

Connected packaging is driving the need to include individual serialized identities to printed products. Converters have options to deliver this, from a simple batch/lot plate change in conventional printing to a fully digital printing platform where each package has a serialized identity included with full color printing.

Converters have invested in hybrid printing platforms – where the economic advantages of large volume flexographic or gravure printing is combined with variable data inkjet printing in-line with print production. This application is likely to be counted on as consumer brands with large packaging volumes adopt the need for item-level identification by printed machine-readable codes.

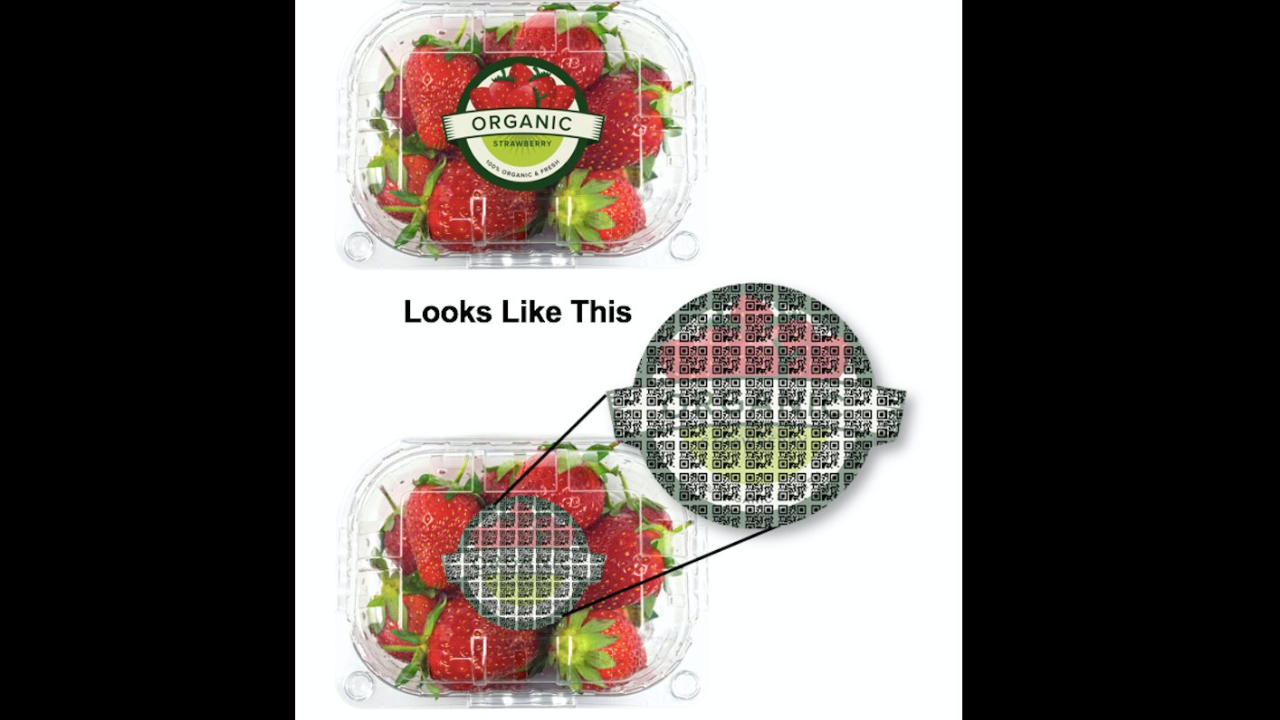

Digimarc offers an imperceptible digital identity across packaging to advance several use cases where the benefit of a generally imperceptible machine-readable code means broader coverage scannable areas, including front-of-package labeling that previously was off-limits to large, unattractive symbology such as a QR code. Digimarc incorporates into existing artwork using the same colors and print configuration to add intelligence with embedded identifiers.

Digimarc has demonstrated the ability to leverage hybrid printing platforms to apply unique digital identities to each label within mass-produced flexographic or gravure print runs. This combination to deliver connected packaging identification supports traceability, product quality management and consumer engagement wit

Getting started

There is an urgency today for both packaging suppliers and brands to lead the implementation of connected and responsible packaging, because recall management, government regulations, and trade requirements are converging rapidly. Converters should ask themselves: how do my customers think about next generation supply chains, IoT, and advanced data and analytics?

How can we add digital links and next-gen barcodes to our products? How are we marketing the capabilities of connected packaging? Brand owners should identify optimized codes for their targeted applications – and then evaluate how to communicate requirements to the product and packaging supply chain.

Education, training and cross-functional alignment on how connected packaging will benefit various stakeholders is a crucial first step for an organization committed to advancing capabilities. Information and services are available from trade associations, industry consortiums, technology providers and professional educators

Digimarc has developed and invested in an automatic identification and data capture (AIDC) platform that enables printers and premedia suppliers to create and orchestrate responsible and connected packaging.

Digimarc has partnered with printers such as Westrock, Berry Global, MCC, CCL and Wipak as well as pre-press agencies SGK, SGS and HL Repro and consumable supplier MacDermid, among many others, to provide education and deliver these solutions to market. This ecosystem represents many of the most intelligent leaders in consumer brand product packaging, and they’re smart enough to know that the future demands packaging that delivers intelligence at every stage in the supply chain.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.