Labelexpo Europe 2019 reviewed

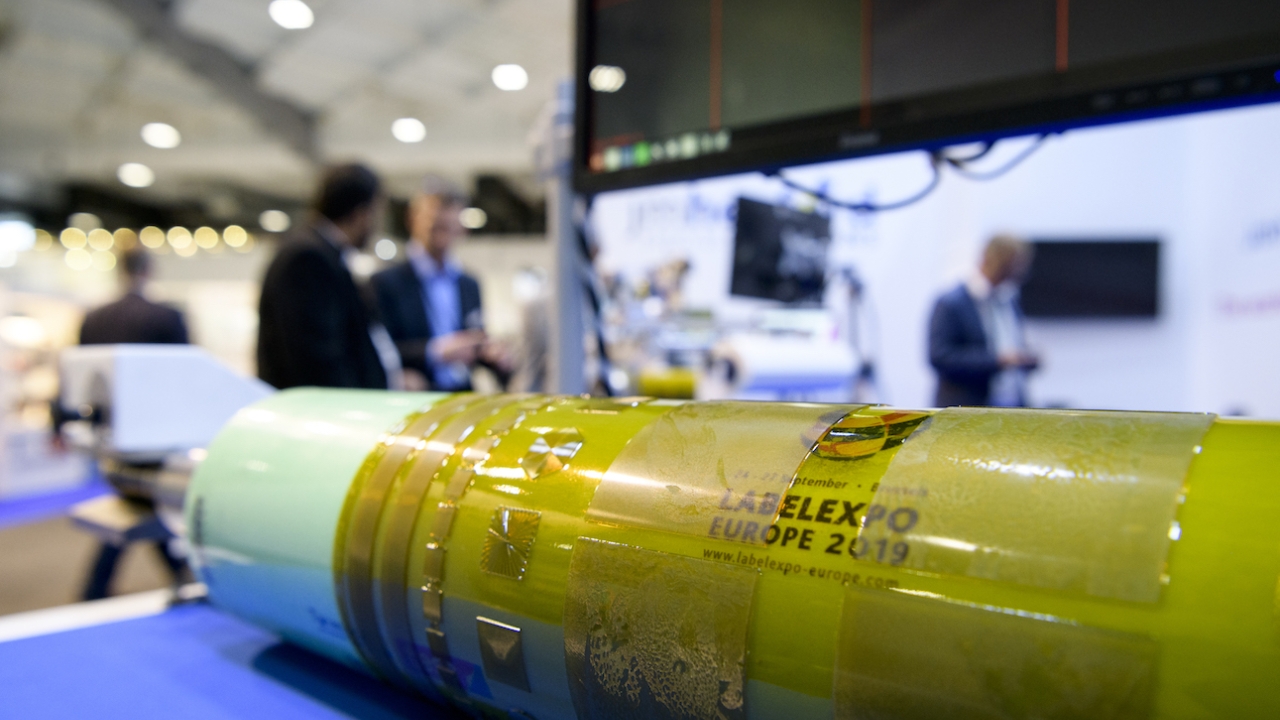

Labelexpo Europe. Don’t be fooled by the name. Not only is the Labelexpo Global Series’ flagship event truly a global show – 140 countries were represented this year, up from 125 in 2017 – but the 2019 edition was a landmark moment in its evolution from a dedicated label exhibition to a technology behemoth incorporating multiple areas of package printing.

Attendees numbered 37,903, broadly similar to 2017’s figure of 37,724, but there were many reasons – both statistically and in terms of the technology on show – to view the event as the most successful in its 40-year history.

As well as the increase in countries represented, show floor space rose from 38,500sqm in 2017 to 39,752sqm this time. There were more exhibitors, too: 693 compared to 679 two years ago. And there were increases in visitor numbers from various markets already sending large delegations, including Brazil (14 percent up), Russia (14 percent), India (8 percent) and Japan (6 percent).

But statistics never tell the whole story. Anecdotal evidence from the show floor suggests that the quality of visitors was improved. Nilpeter’s Jakob Landberg spoke of ‘serious visitors, with serious plans, for serious investments.’ MPS reported record press sales at a show; Konica Minolta doubled its leads compared to 2017. Wherever you looked, it seemed a deal was being signed.

Labelexpo Europe 2017 marked the beginning of a shift towards package printing – particularly flexible packaging. Two years on, it was notable that three of the show’s most significant conventional press launches – Lombardi’s Invicta i2, Nilpeter’s new FA-Line and Omet’s X7 – are geared towards mid-web flexible packaging and shrink sleeve production. These wider-width presses offer label converters opportunities to diversify their businesses into new areas of production.

At the Flexible Packaging Arena, meanwhile, visitors could see demonstrations of pouch printing on a Bobst M6 flexo press and a Xeikon CX500 digital press. The main focus of HP Indigo’s booth was its ‘Digital Pouch Factory’, showcasing stand-up and three-side-seal pouch making printed on its 20000 press and converted on Karlville’s Pack Ready lamination system.

Alongside the show’s mid-web focus, hybrid printing came of age. Inkjet technology’s improvement in speed and print quality was a key theme at Labelexpo Europe 2017; two years on, this translated into a host of hybrid presses on show in a variety of configurations. The usual route may be a flexo press with an inkjet unit inserted in-line. But digital press manufacturers are increasingly partnering with converting equipment suppliers to create hybrid systems based around digital printing and a mix of conventional units. A further route, as evidenced by Gallus’ launch of its Digital Printbar, is a module designed specifically for digital insetting of high opacity digital white or tactile variable varnish.

Sustainability has moved beyond the downgauging of materials. Developments in adhesives allow labels to fall away from the container in a recycling bath, which means that clean PET can be recovered and reused, feeding a circular economy. Labelexpo Europe also saw launches – from Avery Dennison, Synthogra and others – of materials using increasing amounts of post-consumer plastics and bio-based materials. At the Sustainability Insight Café, sponsored by Avery Dennison, Xeikon, Ravenwood Packaging and Sihl Artysio Packaging, visitors could to see how to boost their green credentials with a gallery of the latest sustainable innovations.

Advances in automation, another key trend at the show, are impacting both hardware and workflow. Manual jobs carried out by flexo press operators, such as monitoring print pressure and registration, are increasingly handled automatically by feedback systems. Color is being managed more in pre-press. By the time a job is on the press, operators are not chasing color. And with 7-color ECG systems, the matching of spot colors can also be fully automated and checked in-line on the press.

On the workflow side, artificial intelligence – or machine learning –is beginning to make an impact. Inspection system manufacturers at Labelexpo Europe showed cameras which can learn what a mistake is, referring back to the approved data from the pre-press stage and using that to monitor the job and make adjustment suggestions to the press. Intelligent maintenance systems can predict where problems might occur and prevent them before they do. At the factory level – where workflows are increasingly complex – intelligent systems can begin to help run the plant, automating the choice of printing and decoration processes, planning jobs and buying stock for the warehouse. Not working autonomously, but working as a cyber assistant to human skills and judgment.

Lisa Milburn, MD of Labelexpo Global Series, said: ‘Labelexpo Europe 2019 showed that the global label and packaging printing industry is still as vibrant as ever, and that the show – 40 years on from its foundation – is still a vital platform at the forefront of the entire supply chain.’

A two-day educational program – the show’s most extensive to date – drew in attendees eager to boost their industry knowledge. Three expert-led Label Academy hosted master classes covered the hot topics of Inks, Coatings and Varnishes; Digital Label and Package Printing; and Flexible Packaging, while a workshop covered Self-Adhesive Label Materials.

Read our comprehensive review of the show in the next issue of L&L.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.