Shanghai hosts record-breaking Labelexpo Asia

Expanding its feature content and show footprint, Labelexpo Asia 2017 featured 300 exhibiting companies, including 80 first time exhibitors. In addition to the Digital Trail, Labelexpo Asia hosted its first Smart Zone to highlight new technologies and applications for improving customer appeal and tackling counterfeiting.

Labelexpo Asia 2017 was supported by the Printing and Printing Equipment Industry Association of China (PEIAC).

Digital printing

Amica Systems showed a full-color UV label press. Gemini 330 offers 4/6-color printing including white, varnish and spot color. Gemini 330 can achieve 600x600 DPI and 32mm print width with a print speed of up to 75m/min.

Basch exhibited the Panthera 3322C color inkjet press, with UV optional varnishing unit.

Beijing Shield launched the Shield D6600 variable barcode and data printing system. This modular machine is available for various inkjet platforms.

Dilli’s Neo Mercury digital label press demonstrated by Shanghai Yongxiang features a printing speed of 50m/min, resolution of 600/1,200 DPI and Kyocera inkjet heads. It covers 85 percent of Pantone colors. It can print a variety of materials with no need for coating.

Domino demonstrated its N620i digital press and predicted an upsurge in demand for digital label printing. ‘The Chinese market is moving quickly and adopts technology including the new generation of color QR codes which requires higher resolution head technology,’ said Mario Fanton, director Domino Digital Printing Solutions Asia-Pacific. QR codes are being heavily adopted for track and trace applications, increasingly mandated by the government.

Domino now offers a wide range of configurations for its N610i digital color print engine and Fanton stresses to Chinese customers the importance of finishing efficiency – semi-rotary die-cutting against flatbed for example.

Durst’s Tau 330E UV inkjet press was shown by Fuji Xerox China. The two companies signed an agreement on-site for the Chinese market. The digital color label press exhibited by Envove uses piezo drop-on-demand inkjet technology and can print directly on various substrates including paper, metal foils, PET, PVC, PE and PP.

Flint Group demonstrated integrated digital and conventional technologies at the show, combining a Xeikon 3500 digital press, a ThermoFlexX flexo and letterpress CTP device alongside ink and coating technologies. ‘There is huge growth potential in the Chinese market for digital label production, and it is an important market for Xeikon,’ said Bent Serritslev, Xeikon’s managing director of Xeikon Asia Pacific.

Xeikon’s broader strategy is to play more deeply in the packaging market, according to Benoit Chatelard, president Flint Group Digital Solutions and CEO Xeikon.

Flint Group demonstrated integrated digital and conventional technologies at the show, combining a Xeikon 3500 digital press, a ThermoFlexX flexo and letterpress CTP device alongside ink and coating technologies. ‘There is huge growth potential in the Chinese market for digital label production, and it is an important market for Xeikon,’ said Bent Serritslev, Xeikon’s managing director of Xeikon Asia Pacific.

Xeikon’s broader strategy is to play more deeply in the packaging market, according to Benoit Chatelard, president Flint Group Digital Solutions and CEO Xeikon.

A major focus in the Chinese market is heat transfer labels. The 3500 press on the Flint stand was delivered after the show to Onga for a heat transfer application. Folding cartons are another sector being targeted by Xeikon in China – the 3500 can handle substrates up to 350gsm to roll or sheet.

Guangzhou Trojanjet exhibited the TrojanF1 digital printing machine integrating high-speed inkjet printing, laser cutting and complete post-press system. Modules are available for unwind/rewind, color inkjet printing, stripping, waste discharging, coating, flexo, rotary die-cutting and more.

Haotian exhibited the digital color label press SM210/330. Its features include 1-6 colors, white ink, varnishing or special color printing, print resolution of 600x600 DPI, 324mm width and a high speed of 50m/min.

HP Indigo was demonstrating a WS6800 digital press. The company now has an installed base of 160 presses in China, of which around 60 are 6000-series machines and four are 20000 machines used mainly for flexible packaging. For finishing systems HP Indigo in Greater China works closely with both Brotech and AB Graphic. Comexi is the partner for flexible packaging and Kama for folding cartons.

According to Hendry Feng, Greater China sales director for HP Indigo, there is a new generation of label printers in China using only digital presses. They are using the internet to find customers and allowing them to upload their own artwork. Most HP Indigo customers have moved directly from letterpress to digital, and these are often quite small printers. ‘Often the price of flexo is too high for these companies because of plate costs.’

OKI showed its latest PV701 roll-to-roll label printer, a 5-color (CMYK+ white) system. It’s suitable for multiple applications including food and beverage, chemical, garment and logistic and cultural and sports.

The K series UV inkjet printing system exhibited by Shanghai Lion can be configured flexibly with a data detecting unit, and other automation units such as automatic cleaning, malfunction diagnosing and real-time monitoring.

The UV inkjet printing system exhibited by Shenzhen Chuangsaijie is equipped with imported UV ink which results in excellent attachment and gloss on different material surfaces. It is available for both monochrome and color inkjet printing.

Shenzhen Runtianzhi launched a high-speed integrated inkjet label printing system. The SDW-340 combines 1,200 DPI UV inkjet printing utilizing the Fujifilm Dimatix Samba printhead with a dual laser die-cutting system.

Vorey launched its latest Color DLP VP320C digital label press using advanced S-LED and DELCIS (Digitally-Enhanced Lighting Control Imaging System). The machine can print with a resolution of up to 1,200/2,400 DPI.

Zhejiang King Label exhibited the KTech 700 series barcode printer. It features a patented energy balance system which prolongs the lifespan of the printhead and produces high quality results with low temperature output.

Conventional printing

Spurred by the Chinese government’s ongoing tightening of environmental regulations, flexo printing is gaining greater acceptance in the country and was prevalent on the Labelexpo Asia show floor, as was offset technology

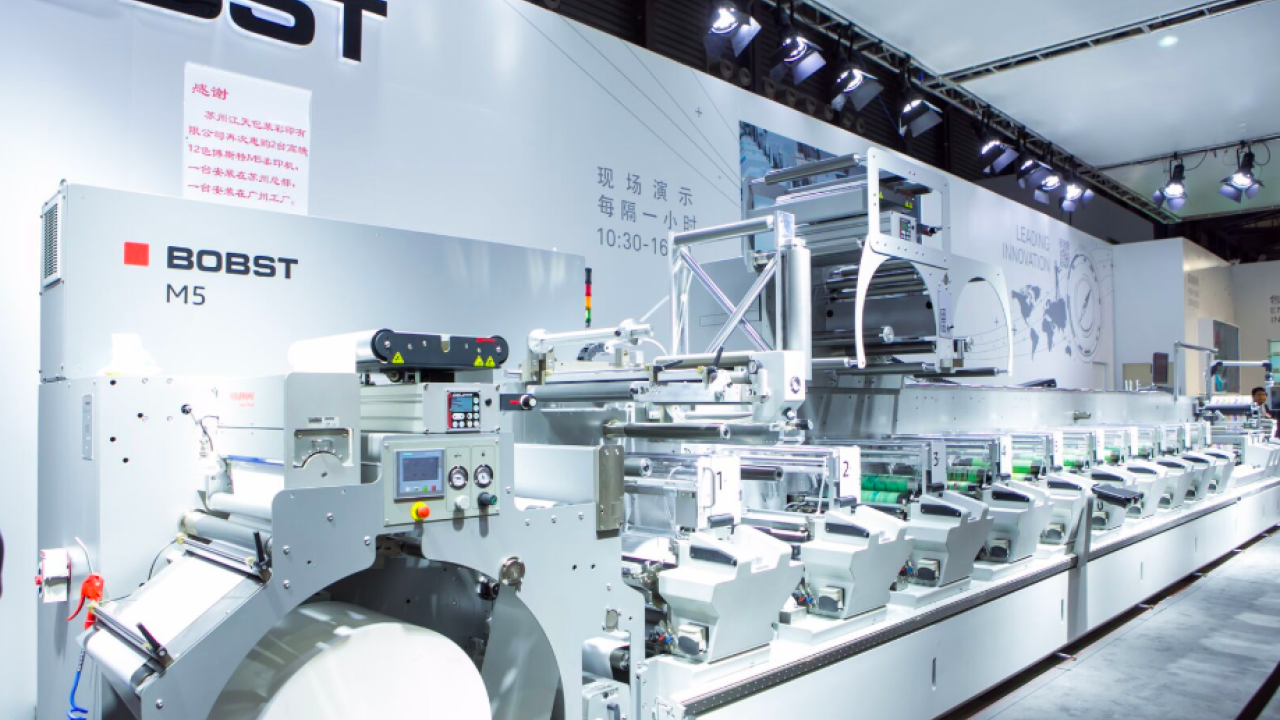

Bobst demonstrated an M5 UV flexo press fully specified to the company’s REVO Digital Flexo specification. This includes fully automated pressure and register control, 7-color process color printing and the involvement of all REVO partners including Flint Group, AVT, Apex, X-Rite, Esko, DuPont and UPM Raflatac.

The press was kept busy producing ten jobs in five minutes during regulator daily demos, with just ten meters of waste between jobs. Bobst REVO specialist Daragh Whelan – who previously pioneered the REVO automation process at converter Americk Packaging – said the Chinese market is now ready for such an advanced machine: ‘It will be of particular benefit to people who don’t have the skills for flexo.’

Codimag demonstrated its latest Evolution 6-color waterless offset press, incorporating for the first time IST’s ‘Hot Swap’ hybrid UV lamp technology. This allows the converter to change rapidly between UV LED and conventional UV at any print station by the simple exchange of cassettes. The power supply automatically recognizes which lamp type is installed. The UV LED lamps are air cooled.

This is the first time a waterless offset UV LED equipped press has been seen at a Chinese show. Along with energy saving benefits compared to mercury UV, the LEDs can be programmed to the print width and LEDs can be switched off during the web reverse phase of the intermittent printing process. Codimag MD Benoit Demol estimates these factors can lead to a 30 percent energy saving compared to conventional UV.

The press on the Codimag stand was sold to China’s Sunrise Printing Company – the company’s second Codimag machine and Codimag’s third installation in China in the last three years. ‘The two Evolution presses we sold in China last year were for the wine label market, although they are now being used for food and pharma applications on a wide range of materials,’ said Demol.

Dowell showed its MF series flexo press aimed at medium and short runs of label, flexible packaging and carton printing. The press has a twin servo and pre-register system, a short web path and modular design allowing UV flexo, gravure and cold foil units.

Hebei Wanjie’s JPS-350 intermittent rotary label press adopts servo driven rollers and an advanced US inking and watering system, which guarantees ink-water balance and color stability at high or low speeds.

Hexiang showed its HX-330 rotary offset press, featuring high levels of automation claimed to feature ease-of-use for operators. Kunshan Jinjian exhibited the 6-color JJ380 waterless intermittent press.

Omet demonstrated a highly specified XFlex X4 press in a series of daily demos. The company’s Southeast Asia managing director Dario Urbinati was impressed with the level of visitors to the company’s stand. ‘Compared to two years ago we had a higher number of people interested in flexo, and the quality of the visitors has improved. We have interest in at least two presses from this show.’

The company maintains a demo center in Shanghai and has an established base of 50 machines in China, including not only XFlex narrow web presses but also wider VaryFlex machines for applications including flexible packaging and tobacco cartons.

Ruian Hongsheng launched the HSS-320/450 flexo press. Ruian Jingda exhibited a multifunctional flexo label press available for both cloth and paper label printing. Zhejiang Hexiang’s RY320 basic flexo press, Baangcheng’s F3/F5 flexo press and Spande’s S7 flexo press were also on show

Zhejiang Weigang Machinery’s ZJR-330/450 flexo press features Rexroth-Bosch servo drive for tension control, 330mm printing width and a high speed of 180m/min. There are 23 servo motors in eight color units and three die-cutting stations in the press. More than 50 of the presses have been installed in China.

Zhejiang Zhongte exhibited its ZTJ-330/520 intermittent offset label presses, equipped with an advanced inking system composing of 23 ink rollers.

Pre-press and workflow

Cerm was present at the show for the first time, announcing the first Chinese language version of its management information system (MIS). Although now part of the Heidelberg group, Cerm has retained its identity as a narrow web MIS specialist and sees great potential for streamlining converter operations in China.

Esko showed a series of new flexo solutions while launching new products, integrated automatic flexo plate-making into automated pre-press workflow. ESKO could provide upgrade service for current users with automatic engines. Meanwhile, the Crystal Optech exhibited CDI Crystal imaging system and XPS Crystal UV exposure units. Yantai Hengli Label bought one CDI Spark 4835 from Esko during the show.

As well as showing its offset CTP, Hangzhou Cron launched a digital flexo imaging machine for the label and packaging market, and the EZColor high-precision digital inking system aimed at sheet-fed offset printers. Hangzhou Eastcom showed its CPT system. Shanghai Aurora exhibited its Aura 400, 600E/S and M800E/S digital flexo engraver.

SPGPrints showed rotary screen printing and laser imaging systems for creating high-quality labels and packaging. SPGPrints’ rotary screen solutions displayed at the show cover every step in the workflow, providing a cost-efficient, productive way of applying numerous eye-catching and functional effects that add brand value. These include the no-label look, raised varnishes, fine linework, small text, metallic foil, security features and Braille up to 250 micron thick, in a single pass.

Inspection

AVT showed its advanced 100 percent automatic inspection systems for narrow web printing, including the newly developed Helios S and Helio II systems. The company has an office in Shanghai and has been selling into the Chinese market since before 2000. Of Labelexpo Asia 2017, marketing manager Aviram Vardi said: ‘You can see the technology shift – flexo is beginning to replace letterpress. With greater speeds and volumes, you need inspection. There is a faster learning curve in China compared to the rest of the world. It is a very important market for AVT.’

Beijing Daheng Image Vison exhibited its E-tag inspection rewind system and pre-press proofing software.

Erhardt+Leimer showed its SmartScan 100 percent inspection system for the first time in China, and its Elscan web monitoring system which combines two high-resolution cameras.

The EyeC ProofRunner 100 percent inspection system, which can operate at up to 600m/min, can be installed on the fastest presses and rewinders on the market. The EyeC Quality Link can transmit the inspection results from the press to an independent computer for analysis and evaluation, with the data then sent to the rewinder to eliminate defective labels.

Guangzhou Pulisi showed its automatic 100 percent inspection system range.

ISRA Vision demonstrated its new NarrowStar narrow web inspection systems, with the company’s Amir Dekel stressing the advantages of the ‘plug and play’ system in which all replacement parts can be installed directly by the converter without requiring an ISRA engineer.

Although a relative newcomer to the narrow web sector, the company is an established player in a wide range of industrial applications including CI flexo and employs 105 people in China.

ISRA demonstrated its latest intuitive interface, which Dekel claimed takes only ten minutes to learn – ideal for converters lacking an in-depth narrow web skills base. The system also incorporates defect management and automated rewinder control.

An alliance between China’s inspection specialist Luster Light and US-based GlobalVision was announced at Labelexpo Asia. Luster will integrate GlobalVision PDF-based pre-printing inspection module which compares the final artwork to the approved PDF. This forms part of the bigger SmartFab project which aims to analyze print defect data from multiple Luster Light installations using artificial intelligence. The system will work to the JND standard – Just Noticeable Defects by the human eye at a distance of 300mm.

The Cloud-based SmartFab will analyze and categorize a wide range of defects, for example those caused by incorrect pressure setting or over-inking. ‘We are building an intellectual model,’ explains Reuben Malz, CEO of GlobalVision.

The next stage will involve working on complete closed loop control of inking and pressure adjustment using the data generated by the SmartFab system.

Italian company Re showed its ReGuard 100 percent print inspection system for the first time in China. Roberto Galbiati, Re’s president, said: ‘We feel the Chinese market is requiring better quality, so it is the right time to invest in China with this product.’ The company has a new partnership with fellow Italian company ACE to distribute its range of web cleaners in China.

Inks and curing systems

Encres Dubuit launched new range of halogen-free inks including UV and solvent-based screen printing inks.

Guangzhou Topcolor highlighted its range of UV flexo, UV screen, UV offset and UV letterpress inks, and water-based flexo inks, metallic inks and special-effect inks.

Hangzhou Toka launched low migration UV flexo and UV offsets inks, which have passed US FDA and Swiss SQTS migration tests.

Phoseon showed its UV LED curing products, which have been optimized for thin and thermo-sensitive materials. They eliminate the production of noxious gas while enhancing the safety of working environment. The UV LED lamps can make full and efficient use of the power supply, which extends the product lifespan and reduces running costs.

UV Energy exhibited its latest UV LED curing products, compatible with traditional printing methods and available for all conventional UV inks, varnishes and primers. Its maximum speed is up to 350m/min, and is available for flexo, offset, screen, letterpress, gravure and high-speed digital printing.

Zeller+Gmelin showed its latest-generation Uvaflex-FCM-Y81 UV flexo inks, which offer a higher level of security in terms of migration and which feature an especially low odor.

Converting equipment

Brotech announced its entry into the wider packaging finishing market, providing ‘one-stop’ finishing systems for flexible packaging and folding cartons as well as for labels. Brotech has already developed finishing systems for HP Indigo’s WS6800 and a system for the 20000 press. Now a wider, 32in-wide system is under development incorporating a range of finishing modules including lamination, coating, flatbed die cutting and sheeting. The company’s managing director Ramon Lee also announced development of a 520mm-wide flatbed die-cutter to join the existing 350mm-wide FB cutter.

New on the Brotech stand was a semi-rotary flexo module for the SDF520 finishing machine, alongside lam/delam and turnbar. ‘This cuts down spending on different sized cylinders,’ said Lee. The SDF520 labels but also flexible packaging and light cardboard up to 250gsm.

Changrong (Yingkou) showed its LC330RE, LC340S and LC590SF laser cutting-engraving machines. The GCC LabelExpress laser die-cutter is a high-speed system that delivers high flexibility and great precision with an intuitive operation. With the CCD module, auto-feed system, waste removal module and rewinder device, as well as an optional slitting module and self-developed SmartControl Label software, LabelExpress provides a fully automatic digital cutting system for roll labels and PU thermal transfer films.

Spanish finishing equipment manufacturer Enprom was present for the first time at Labelexpo Asia, having appointed Sinotrade Service Corp as its Chinese distributor last year. Sales manager Enric Sucarrats said: ‘We are enthusiastic about the potential for our technology in the Chinese market.’ The company focused its narrow web machinery, including equipment for sleeve and in-mold labels and cutter stack system for beer labels.

ETI Converting Equipment, which recently celebrated the 10th anniversary of its manufacturing operation in China, was promoting its Cohesio, Metronome and Pellicut systems. Under the direction of Waley Xuan, ETI Shanghai employs around 60 staff, including managers, engineers, mechanics, electricians and technicians. The recently launched Pellicut die-cutting system can slit materials down to 12 micron at high speed. The company recently relocated Chloe Bayzelon, international technical coordinator and daughter of CEO Francois Bayzelon, to its Chinese office.

Hontec Machinery showed its laser die-cutting system. Kampf made its Labelexpo Asia debut, showing the Conslit slitter – whose fully automatic unloading function reduces labor costs and increased efficiency.

Martin Automatic showed its butt splicing and non-stop automatic unwinding machines, which can help users improve production efficiency and reduce waste.

Rhyguan showed its TOP-330-2 multifunctional intermittent rotary die-cutter, which can switch between rotary mode for in-mold labels and intermittent mode for self-adhesive labels. The company also showed Kiss-330SD high-speed flatbed die-cutting machine, Smart-HMS330 slitter and rewinder inspection system and Won-S330 automatic high-speed slitter rewinder.

Substrates and adhesives

Armor, which has operated an office in Shanghai for nearly 10 years, launched its rebranded Inkanto thermal transfer ribbons, including new products AXRTX and AXREL.

Avery Dennison showcased a wide range of label and packaging materials in five different zones at its booth, including products for cold chain logistics, inkjet printing and smart labels. Also on show was a new hotmelt adhesive label and a PET-based material range. Sustainable materials were on display including a recycled paper facestock and FSC-certified facestock.

Dow Corning launched its Syl-Off 7953 emulsion technology in China, designed for manufacturers using both in-line and offline coaters. Key advantages include better silicone anchorage, lower coat weights and less ‘rainbow’ effect, which increases aesthetic appeal.

Charlie Zimmer, global strategic marketing director, Packaging, Elastomers & Telecom at Dow Corning, said Syl-Off 7953 is ideal for the Chinese market as the government puts more restraints on solvent use.

Dragon Foils exhibited its FXC general/holographic flexo cold foil series, OSC offset/holographic cold foil series and DT digital printing foils.

Durico showed its new translucent film, which was launched earlier in the year. It is aimed particularly at the food market, where there is a trend for translucent labels for products such as meat.

Gold East Paper showed a coated paper featuring good water and distortion resistance, aimed at labels for cans and bottles. ITW Thermal Films exhibited wax/mix/near-edge/resin/washable ribbons and TTO online printing barcode ribbon.

Innovia Films was showing BOPP alternatives to paper, including a tactile coated film for the beverage market. For beer crate labeling, the company showed a BOPP 92 micron film in clear and white. A thinner grade version of its Squeezable label film, in clear and white, was on display for the health and personal care market.

Lintec showed industrial low-adhesive tapes and double-sided tapes.

Shanghai AKO launched a recyclable PET ultrathin film of 12 micron compared to the traditional 23 micron, and, at 30g, half the usual weight. Shanghai Jinda exhibited various adhesive, release and packaging products covering paper, film, foils, cloth, tapes and release liners.

Soontomax showed its water-based PS adhesives, with separate ranges available for film and paper incorporating some 100 products suitable for a wide range of end uses.

UPM Raflatac showcased its new Thin Film range of materials which allows more labels on a roll, less downtime for roll changes and reduced storage and transportation costs. Also on show were ice-resistant materials for wine labeling; food labels with a new adhesive approved for direct food contact; and materials for garment and lubricant applications. UPM Raflatac also promoted its RafCycle recycling system, and the first RafCycle partner certificate in China was awarded to Hangzhou Changli during the show.

Univacco showed its new LTM-08 cold foil as well as a new cold foil for in-mold labels. Wacker launched two new silicone release emulsions. Zhejiang Guanhao showed a thermal-sensitive film adhesive aimed at medical, frozen food and tire applications. Zhongshan Kinglabel showed a halogen-free flame-retardant material. ZongLvQuan exhibited the MDO PETG shrink film.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.