Polytag, Saica Flex, and Paragon Inks announce strategic partnership

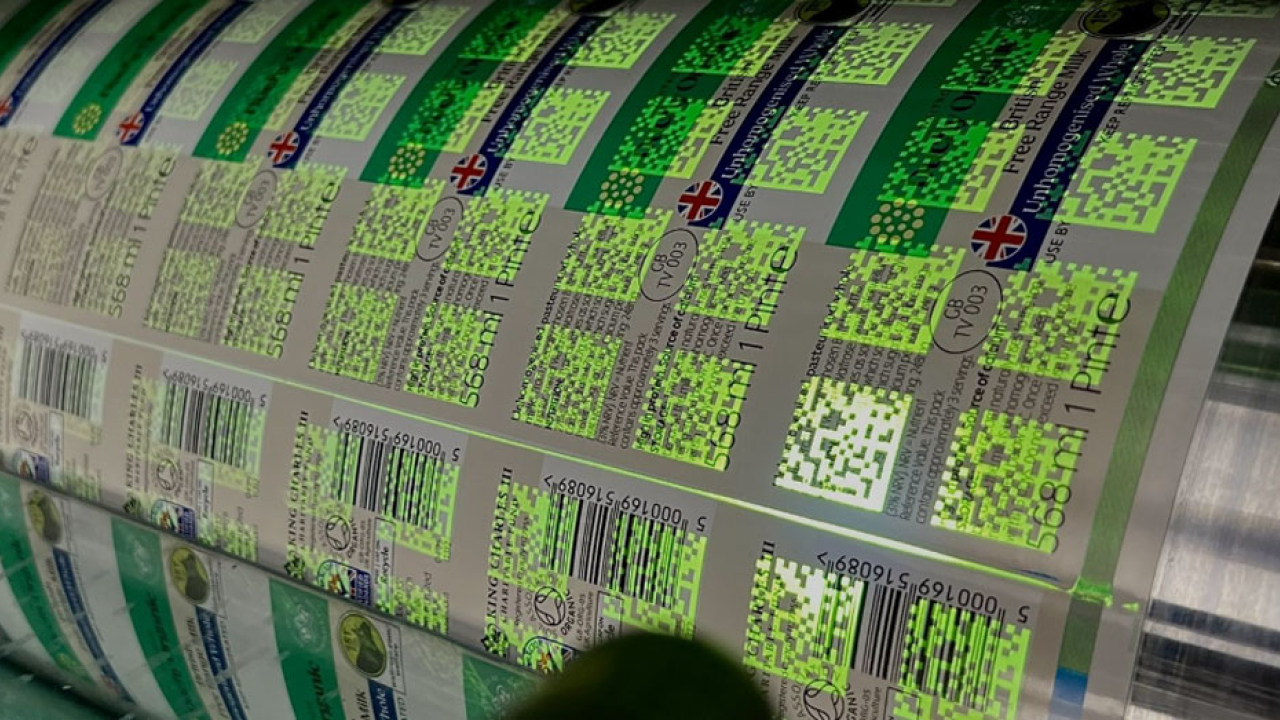

Polytag, Saica Flex, and Paragon have announced a strategic partnership to deliver UV-tagged packaging labels, designed to provide brands with real-time environmental data.

This collaboration will combine Polytag's detection technology, Saica Flex's packaging production, and Paragon Inks' specialist UV inks.

Alice Rackley, CEO of Polytag, said: 'What makes this partnership work so well is that all three companies are aligned in purpose. From day one, the focus has been on delivering practical, scalable solutions that make a difference for brands and the environment.'

The collaboration is already having an impact; labels for Waitrose milk cartons are now in-market and actively generating verified, reliable recycling data.

The labels carry invisible UV tags, printed with Paragon's ink products. Once they enter the recycling stream, Polytag's detection systems scan the labels and capture detailed, item-level data. Using this data, recyclers can track in real time which products enter the recycling stream, measure recovery rates, and demonstrate compliance with regulations such as Extended Producer Responsibility (EPR), thereby facilitating the sharing of this information with brands.

Crucially, the method integrates seamlessly and cost-effectively into existing packaging and printing workflows. Saica Flex's close collaboration with Waitrose, combined with its experience in this specific packaging, enabled rapid and reliable deployment without disrupting established supply chains.

Francisco Barrera, sales and marketing director at Saica Flex, said 'We knew from the start that adoption would depend on keeping things simple. Brands need solutions that fit naturally into their operations and current production environments.

'This product works across the entire packaging lifecycle, from printing through recycling with minimal disruption. It gives brands meaningful insight, while remaining practical and viable even for high-volume products like milk cartons.'

Alice Rackley added: 'And because it's built on GS1 global open standards, the UV tag solution is ready to scale across multiple sectors and applications, allowing brands and recyclers to participate fully in building a transparent circular economy.'

The UV inks underwent extensive development and testing to ensure full compatibility with standard waste management processes. The labels can be chipped down or separated through flotation, and any residual ink behaves in-line with other approved UV products, ensuring no contamination of recovered materials.

Barbara Paterson, technical director at Paragon Inks, said: 'Creating the UV inks was a technical challenge. They needed to remain detectable by Polytag readers across a wide range of colours, substrates, and packaging formats, even after packaging has been crushed or otherwise processed.

At the same time, the inks had to meet strict food-safety and environmental requirements. Two years of development, testing, and iterative validation went into delivering a technology that is reliable, safe, and fully compatible with existing waste management operations.'

Martin Fowler, global sales director at Paragon Inks, said: 'Seeing the labels generate real data in a live waste stream validates all the work that went into development.

'It proves the system works as intended, and this is just the beginning; the potential for other products and sectors is enormous.'

The UV label is ready to scale across multiple packaging formats, from beverages and dairy to a wide range of consumer goods, delivering actionable, verifiable environmental data and enabling measurable progress in environmental performance.

Francisco Barrera concluded: 'This partnership is about more than labels. What we're creating is exciting: packaging that tells a story about sustainability and waste management.

'Through this collaboration, we're giving brands insight and control over their environmental performance, making recycling measurable, actionable, and scalable. It's a real game-changer for the industry, and we encourage more brands to embrace this solution to make a tangible, positive impact on the circular economy.'

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.