German converter commissions 5,000th ULT-300 cold glue sensor

Folding carton specialist Kroha in Barleben, Germany has commenced operation of the world’s 5,000th ULT-300 cold glue sensor from Baumer hhs.

Kroha uses the sensor on an FF 52i folding carton gluing machine from Kama, which was retrofitted with a top gluing nozzle to enhance the machine’s flexibility. In the gluing nozzle, cold glue is applied to folding cartons by a P-500 application head, also from Baumer hhs. Immediately after application, the glue is scanned by the ULT-300 sensor. It checks the position of the glue, but also those areas where no glue should be applied. The ULT-300 detects narrow and wide glue areas, as well as lines and dots on a variety of substrates. With its auto-teach function, the sensor automatically detects the glue pattern.

Installed at Kroha in 2015, the FF 52i is equipped with a bottom disk gluing unit, monitored by an LNT-300 sensor that checks whether the side seams were applied with the correct quantities of glue. A CT-30 color sensor with integrated code reader is positioned downstream of the FF 52i’s feeder.

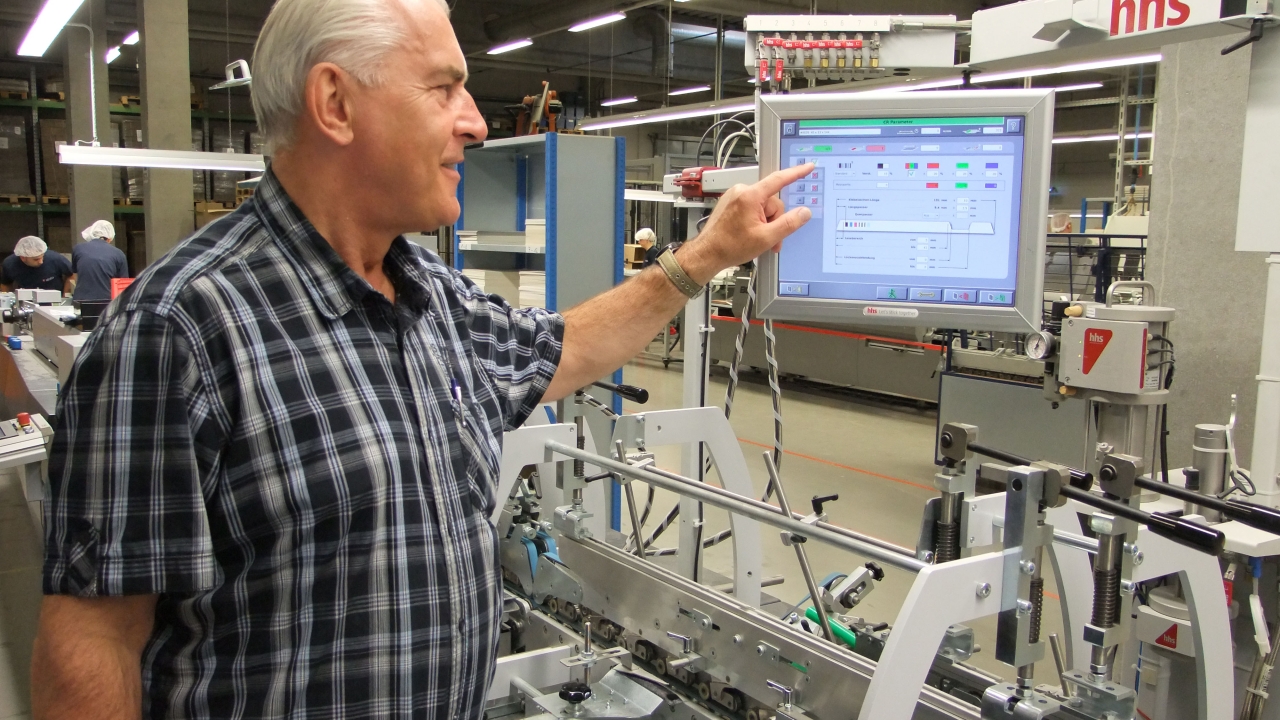

The entire system is controlled by an integrated Xtend2 system. Its central display gives machine operators an overview of all the Baumer hhs equipment. What is more, the Xtend2 system with its tracking and ejecting module controls the folding carton gluing machine’s ejecting unit, which ejects all flawed packages from the process. In this context, the equipment from Baumer hhs functions according to the fail-safe principle: Each folding carton produced is considered to be defective until all sensors integrated in the machine have identified it as flawless.

Hans-Peter Blockus, head of folding carton finishing at Kroha in Barleben, said: ‘Thanks to the reliability and performance of the technology from Baumer hhs, we can guarantee our customers one-hundred percent quality assurance in product finishing at both our plants in Miesbach and Barleben. Especially for our pharmaceutical customers, this is a basic requirement for their collaboration with our company.’

Kroha also uses an Xmelt hot-melt system from Baumer hhs at each of its two facilities. These systems are used, for instance, when the instruction leaflets are not to be inserted inside a package, but rather on the outside into specially glued flaps.

Markus Leier, sales head at Baumer hhs, added: ‘The installation and start-up of the 5,000th ULT-300 underlines Baumer hhs’ worldwide leadership in this sector. We are pleased that this record-breaking sensor was delivered to Kroha, one of our oldest customers, with whom we have launched so many pioneering projects. Working closely, we have continuously expanded the possibilities for glue application and quality assurance in package production in the pharmaceutical and other industries.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.