Coca-Cola leads custom label revolution

A breakthrough project involving eight HP Indigo label converters across Europe and mixing both conventional and digital print technologies has allowed Coca-Cola to rewrite the rules on promotional marketing. Andy Thomas reports

Coca-Cola has revolutionized the world of promotional marketing with the launch of a project which saw many millions of labels printed with customized data by a network of digital and conventional printers across Europe.

The project saw Coca-Cola marketing departments in more than 30 European countries supplying the 150 most popular local names, together with a range of slogans based around sharing Coca-Cola with friends and family. The names were printed randomly on labels for 0.5L and 375ml bottles of Coca-Cola® regular, Coca-Cola zero® and Coca-Cola light™.

‘We wanted consumers to share both the physical bottles, and also share the experience on social networks,’ says Coca-Cola marketing manager Marit Kroon. ‘You can share a virtual Coca-Cola with friends and family. You can play with the virtual bottle then go and find the real bottle. You can trade bottles if you can’t find what you’re looking for. What can be more personal than a name?’

Gregory Bentley, from The Coca-Cola Company’s packaging innovations group, started looking at the project from a technical angle in January 2012.

It was decided the labels would be printed by a combination of conventional (CI flexo/gravure) and digital printing. After extensive research, Bentley chose the HP Indigo printing process, primarily because it lays down the same weight of ink as flexo or gravure, and for its color consistency.

The project team cut down the company’s 40 conventional label converters in Europe to a more manageable 10 for this project, spread geographically to match the nearest bottling plants.

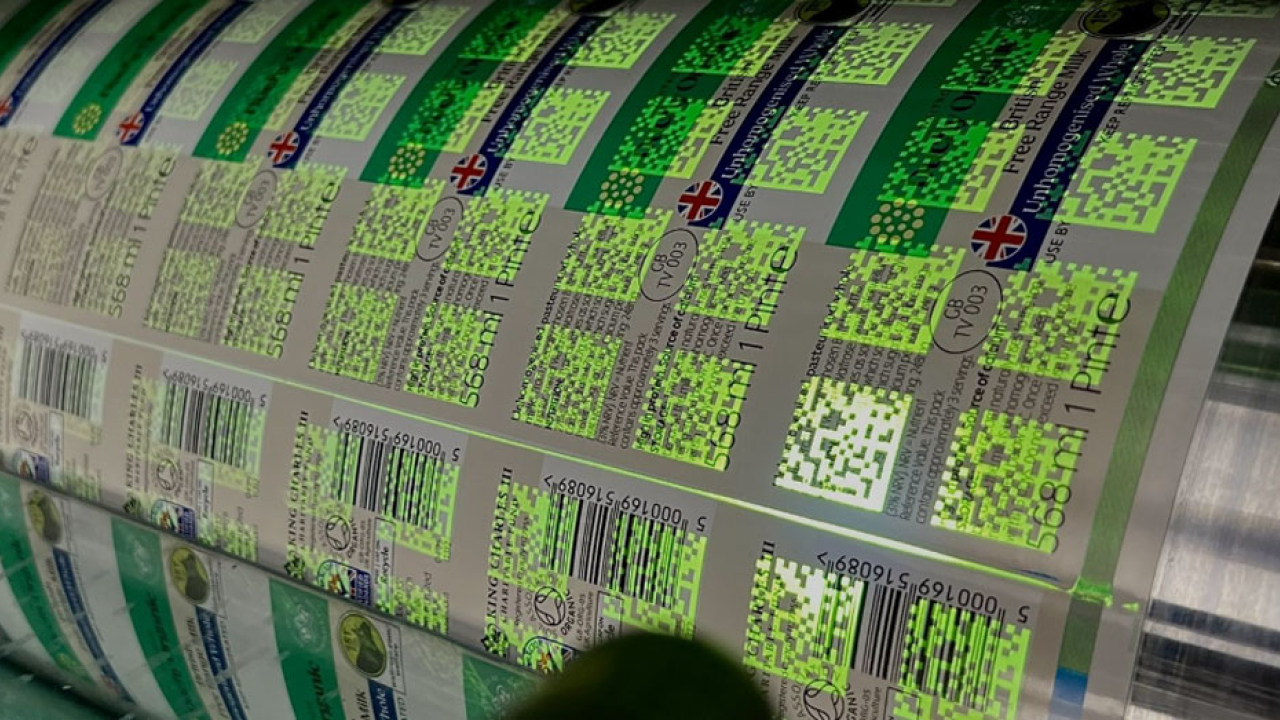

The labels were first conventionally printed, either CI flexo or gravure, leaving a blank panel and a re-registration mark for overprinting by the HP Indigo presses. This panel had to be coated in-line with a water-based HP compatible primer, which presented its own challenges.

Given the complexity of these workflows, Peter Overbeek, managing director at leading Dutch digital label converter Eshuis, offered to handle the entire digital printing side of the project. Eshuis already handled personalized shrink sleeve label production on behalf of Heineken, but this was to be on an altogether different scale.

It was a radical departure for Coca-Cola to outsource print management on this scale, but given the unique situation, Overbeek’s offer was accepted.

Overbeek identified a network of eight European digital converters with HP Indigo WS6600 presses whom he believed could handle the work and were in the correct geographical location. The printers were Rodata (Romania), Carini (Austria), Rako (Germany), Amberley (UK), Auraprint (Finland), ForLabel (Greece), Eshuis (Netherlands) and Robos (Germany)

HP set up full time engineering teams across Europe to support the eight digital printers with spare parts and round the clock maintenance and callout. The extensive remote monitoring network used for HP’s commercial inkjet presses was adapted to the industrial market for the first time.

The final result was a triumph of technology, organization and sheer determination. Multiple millions of labels were printed, applied and sent to warehouses in preparation for the launch of the campaign in May.

‘Eshuis has delivered the project perfectly. We could not have done that on our own,’ says Gregory Bentley.

For the full story, see the next issue of Labels & Labeling, publication date June 2013

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.