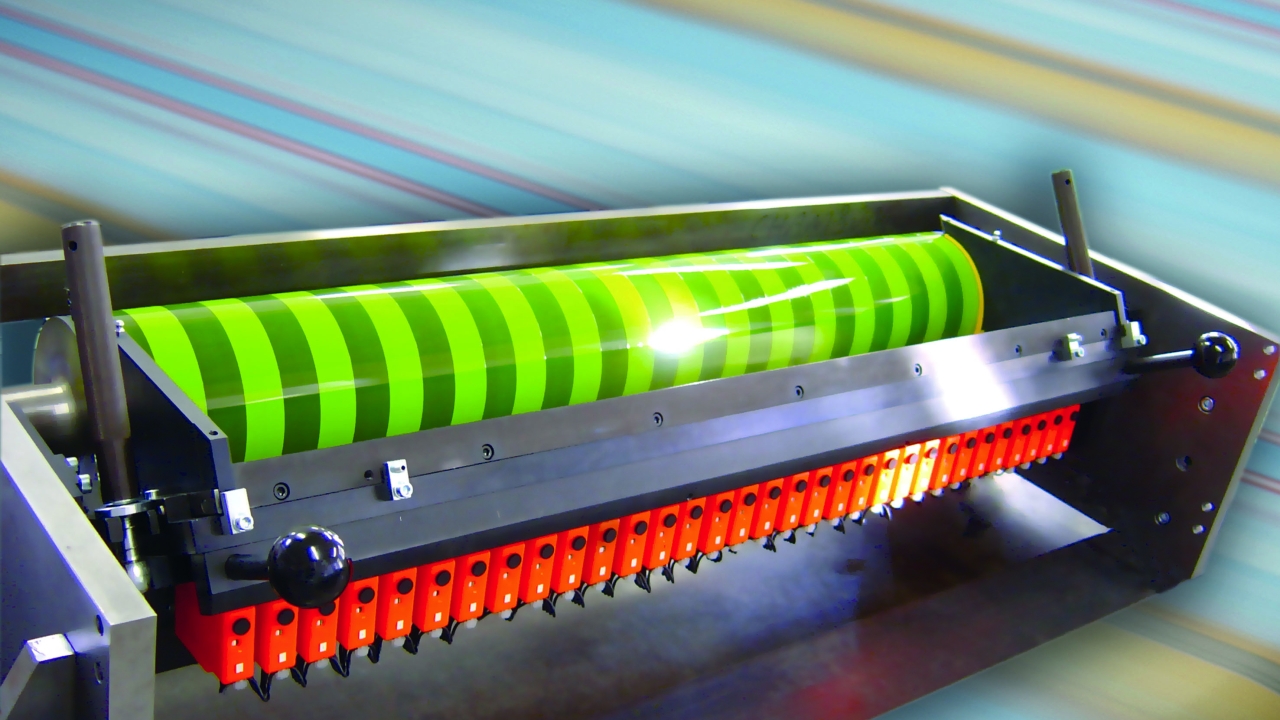

BST eltromat develops new ink fountain control system for offset printing

BST eltromat has developed FSS 15, a new system for ink fountain control in offset printing that is the successor to the company's previous ink fountain control systems developed for this printing process.

In combination with the AR 4000 register control system for offset and hybrid printing presses, as well as a variety of web video inspection and 100 percent inspection systems, BST eltromat said FSS 15 offers offset printers ‘perfect’ management and quality control of their printing results.

FSS 15 also features intuitive user prompting via a touchscreen interface. The ink gap can be set with an accuracy of one micron. The ink zones can be adjusted singly, in groups or in their entirety. The function and position of the ink key drives are controlled fully automatically. Moreover, ink profiles for follow-up jobs can easily be defined, and any number of repeat jobs can be saved in the main memory.

Above and beyond the standard functions, BST eltromat offers a whole range of different options for the FSS 15 that allow customers to flexibly expand the performance of their ink fountain control system. For example, BST eltromat supplies finecolor ink fountains with laser-cut precision blades and special seals, and a mechanism for ink key adjustment, resulting in unrestrictedly reproducible gap widths between ink blade and ink duct roller for all ink zones, and permitting even higher precision in ink adjustment. The finecolor ink fountains are available for various types of printing press and in any required printing width. Other options include variable-inclination desks for print sample evaluation, as well as a ductor roller, ink vibrator and damping unit control system for different machine types.

With compatibility with existing ink fountains and machine interfaces, older BST eltromat systems for ink fountain control can be replaced with FSS 15 with a minimum of effort. In addition, the format and the interface to the pre-production stage (cipcon) are compatible, making it suitable for retrofits as well as new installations. In the case of retrofitting of existing combination systems for offset printing, the ink fountain control, register control and web video functions can be unhinged individually.

Regardless of the printing width and the number of printing units, the FSS 15 ink fountain control system allows simple handling for quick print preparation. In this way, the new system, which is designed to meet the highest demands on color precision, enables offset printers to achieve higher productivity and greater efficiency on the press by minimizing set-up times and paper waste. Savings of up to 30 percent on waste and time can be achieved if the cipcon CIP3 data converter is used for job-specific pre-setting of the ink zone and ductor profiles.

Karsten Barner, project manager for offset systems at BST eltromat, said: ‘Given the enormous demand from the offset market, we decided to develop this new ink fountain control system. The FSS 15 ultimately gives our customers the opportunity to migrate to innovative ink fountain control. It offers both great operating convenience and an excellent price-to-performance ratio at the same time.

‘We consistently paid attention to ensuring that our customers can smoothly replace their existing solutions with the new ink fountain control system, without otherwise having to modify their workflow in any way.'

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.