Enprom launches labeling machine line

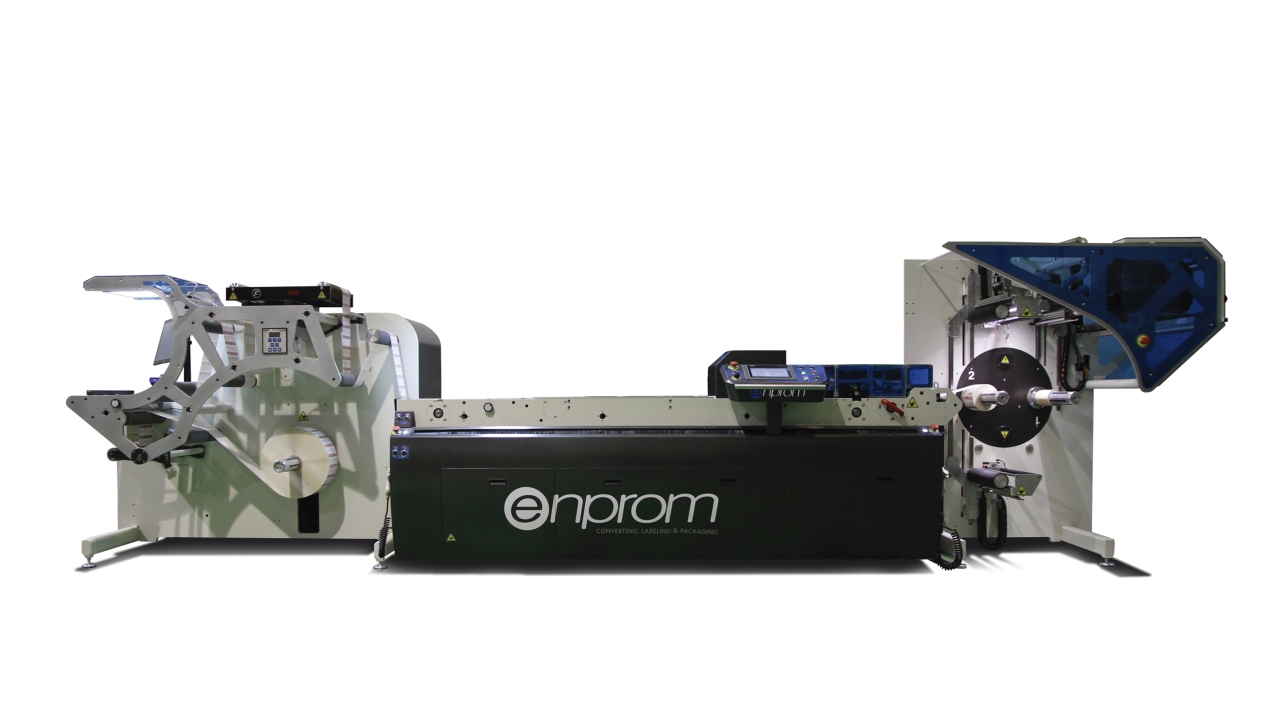

Enprom Packaging, based in Sant Julià de Ramis near Girona in Spain, has developed a new line of machinery for the narrow web sector, and specifically for the labeling market.

The new line is based on the company’s existing eSDC model and employs a modular concept, meaning the machine can be configured according to the needs of the customer and meet their specific needs.

eSDC allows several unwinder and rewinder configurations, as well as integration into the central body of rotary and semi-rotary die processes, 100 percent inspection, inkjet marking, laser cutting, label insertion and RFID. In-line printing can similarly be integrated.

The labeling line also includes a range of machinery for the shrink sleeve sector. Enprom’s eRS sleeve forming machine allows a high reliability in the production of sleeves, with a robust design the machine achieves high productivities and working speeds, Enprom claims. A motorized roller solvent applying system improves current application systems, as the roller applies the solvent evenly avoiding blocking problems and completely eliminating edge flanges. Owing to a synchronized motorization with the machine speed, the technology allows a high reliability of application throughout the production process, even in acceleration and deceleration.

Further, the machine can incorporate in-line inspection equipment, which is said to guarantee 100 percent effectiveness during inspection as it stops the material to solve the defect in-line.

A cutting machine allows the product to be finished in formats or in transversally pre-cut reels.

Enprom Packaging is exhibiting its technologies at Labelexpo Europe 2017.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.