Esko releases WebCenter 12

With the release of WebCenter 12, Esko responds to two distinct packaging and consumer trends: the proliferation of product variations driven by mass-customization and personalization; and the increased pressure on regulatory compliance, with the need to accurately incorporate the required regulatory information on packaging and related materials.

According to Jijo Dominic, product manager web solutions at Esko, WebCenter 12 aims to address four challenges directly originating from these market trends: 1) Keep every stakeholder informed; 2) Manage long approval cycles; 3) Manage the overall packaging process from design to shelf; and 4) Handle versions of packages and labels.

1. Keep every stakeholder informed

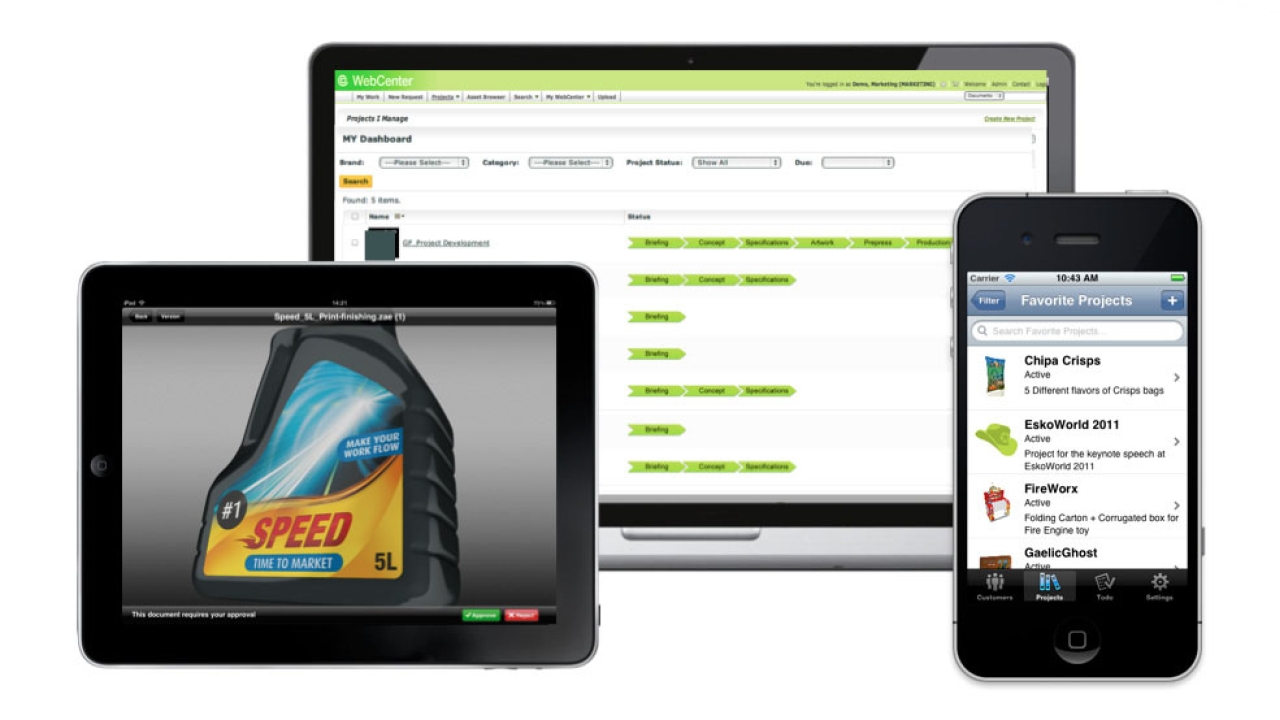

Following its successful introduction of communication ‘on the go’ for iPads, whereby files can be accessed anytime anywhere, WebCenter 12 now extends this capability to iPhones. ‘This enables the sales team to get updates on the progress of a job before visiting a customer,’ commented Dominic.

Built-in integration with Automation Engine and ArtiosCAD and enhanced third-party interfacing capabilities makes the integration of WebCenter into existing workflows fast and easy. WebCenter 12 acts as a Web-to-Production portal and involves the packaging buyer more deeply in package design and production. Design requests are automatically created and a range of tasks are executed on the workflow server without any operator intervention.

2. Manage long approval cycles

A smooth approval process is essential to streamlining production, and that is something WebCenter users are already effectively harnessing. The WebCenter tools that manage a chain of approvals deliver immediate return on investment. This is further strengthened in WebCenter 12 with enhanced compare capabilities, which highlights the alterations by blinking or displaying the intensity of variation for easier location and review. In addition, the Viewer allows real time collaboration on multiple pages as well as online quality control of printing plates.

The new WebCenter reporting function is devised to help businesses measure and report their success internally and externally. Not only will WebCenter users be able to track savings made through improved workflow practices and processes, they will also be able to communicate those values to their clients in a better way.

Dominic explained: ‘There might be one link in the approval chain that is generally the slowest to respond. Using the reporting module, this shortfall can be identified and addressed.’

‘The regulatory requirement to have braille content on pharmaceutical packaging has created a new challenge in the packaging approval process,’ he added Dominic. ‘This demands easy to use tools for the legal department to review content in braille and for the production team to verify how it can be achieved best.’

Through collaboration with Global Vision, Esko has been able to take these capabilities even further so that Braille text can be scanned and verified by a reader that will translate it to prevent errors. ‘This approach can also be applied to barcodes,’ said Dominic. ‘Problems in packaging design that result in regulatory action or consumer complaints predominantly originate from errors with barcodes and text. We have listened to our customers and added simple tools to eliminate these pain points.’

3. Manage the overall packaging process from design to shelf

How to capture all design and production specifications of a packaging project to deliver error-free print? How to collect data from the right people and share it with the right people at the right time? How to make ordering of reprints an easy process?

To answer these questions, WebCenter is enhanced with cascading fields. These fields provide requirements in an intelligent manner with smart filtering and auto filling, rich text fields to provide long briefs and pictorial labels that explain concepts visually. WebCenter 12 standardizes the overall project request, prevents errors and lost data and minimizes human intervention.

‘Effectively managing the “briefing to delivery” process of packaging development is crucial to place the product on the shelf on time,’ explained Dominic. ‘That is why we focus heavily on enhancing process management capabilities and make it easier to build complex processes using a visual canvas. In WebCenter 12, we added simple but extremely effective capabilities to automatically name projects, assets and dedicated tasks.’

4. Handle versions of packages and labels

‘Each individual element of a packaging design created in the development process is an asset. Managing those assets and re-using them is critical for keeping production cost under control,’ said Dominic. ‘To achieve this, WebCenter 12 is extended with user friendly and very powerful asset classification and searching capabilities with a fully customizable graphical asset browser based on document metadata and custom attributes. Furthermore, customization creates different asset browsing views depending on the profile of user. For instance, a brand manager can browse through assets using a brand and product hierarchy while a printer can browse through the assets using printer and print related search terms. Customers can effectively set their own classifications for easy retrieval.’

The end-goal: improved packaging lifecycle management

‘Fully integrated with the pre-press front-end and our business systems, WebCenter 12 delivers us an end-to-end packaging process management,’ commented Dave Gilfillan, technical manager for The Malting’s site at SGS Packaging Europe. ‘Both packaging buyers and packaging suppliers effectively work together on one single platform. Design requests and order forms are presented in a user friendly interface. They trigger the start of a nicely laid out range of tasks and invite different stakeholders to actively participate in the process.’

‘WebCenter evolved from a mere online approval tool to a professional packaging management solution, ensuring value throughout the packaging supply chain,’ concluded Dominic. ‘Today, over 100,000 users work with WebCenter on a daily basis to solve a number business challenges, ranging from long approval cycles, indirect labor to direct labor ratio out of sync, looking for ways to differentiate themselves from competition and so on.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.