Phoseon Technology extends narrow web retrofit

Phoseon Technology has launched the FireJet FJ601 UV LED curing system, claimed to simplify retrofits with a self-contained air-cooled design.

The new air-cooled curing system offers customers process stability with Phoseon’s patented TargetCure technology that provides users with stable, consistent and precise UV curing output. TargetCure enables converters to run food and medical safe jobs using LED low migration inks in addition to standard label and shrink-film jobs. The consistent and stable output of the FJ601 provides repeatable results with each run for a high-yield process.

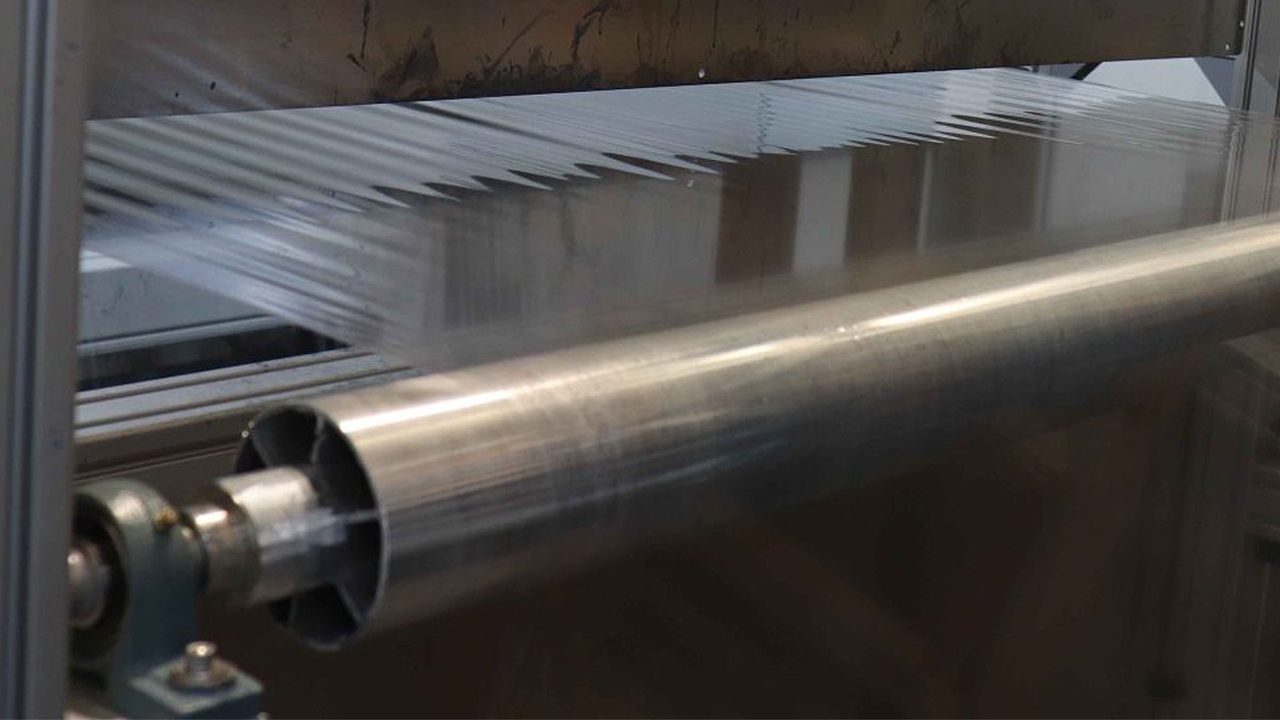

With a form-factor optimized for narrow web presses, the FireJet FJ601 is ideal for a wide variety of flexographic, web offset and rotary screen applications.

Phoseon’s FJ601 light sources deliver high-power output for press speeds up to 750fpm (230m/min), and are available for typical web-widths ranging from 8-20 inches (200-500mm). FJ601 is a low-maintenance system with simple air filter replacements — no tools required.

Phoseon offers fully integrated LED retrofit options for narrow-web printing that consist of station-by station building blocks including light sources and the Flex Tower modular power and control system. Phoseon’s LED technology offers converters the ability to print on thin heat sensitive substrates at fast curing speeds with a reliable curing process.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.