Rotary Technologies launches digital die-cutter

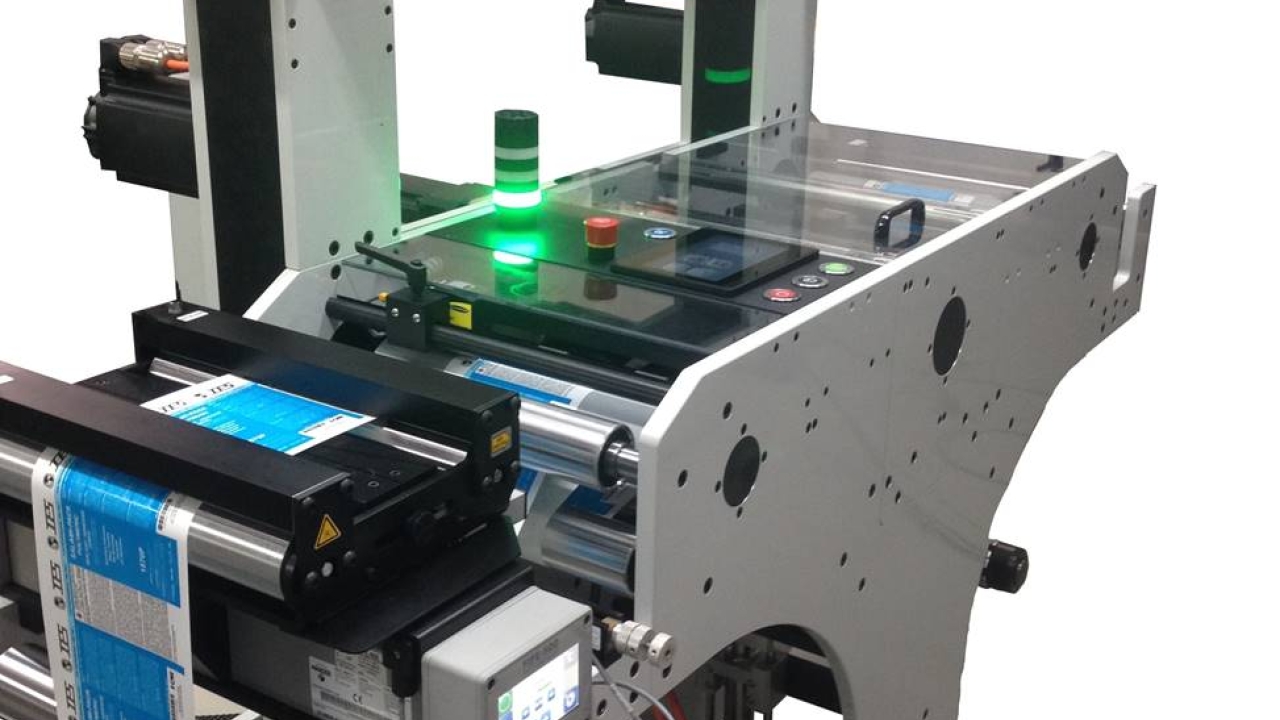

Rotary Technologies, a US manufacturer of reregister systems and diecutting equipment, has launched the TCC 3300 rotary diecutter, specifically targeted at the digital print market.

The TCC 3300 can operate in both in-line and off-line modes. Like semi-rotary die cut technology the TCC 3300 uses a single magnetic cylinder with flexible dies, but the web does not shuffle back and forth like in a semi-rotary system. Instead the web is accelerated past the die cutting gap, allowing a maximum speed of 300 ft/min (106m/min) to be achieved in full rotary mode.

The TCC 3300 completed its beta testing at Southern Tape & Label, where it has been running full production jobs for several months.

‘We have been using Rotary’s reregister system on our flexo presses for years for our digital finishing and were excited when they approached us with their new diecutter,’ says Bob Ramsey Jr., Southern Tape & Label. ‘The TCC 3300 is extremely efficient and sets up fast. We’re able to finish more jobs per day, allowing future growth of our digital business. In the near future we will be moving the TCC 3300 inline with our Jetrion press to print and diecut at the same time.

‘The TCC 3300 is highly automated and efficient. It actually brings itself into register’

The 8 servo axis diecutter has a compact design using 3.5 x 6 feet of floor space, and has an approximate 15’ web path from unwind to rewind. The TCC 3300 uses a fixed magnetic cylinder for mounting industry standard flexible dies covering a range of label repeats between 7 ½ - 15 ¾ ins. The maximum speed is 300 ft/min depending on the label repeat.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.