Maan Engineering details early success with Inlinerless module

Maan Engineering has detailed the early success it has recorded with its Inlinerless module, with the first unit sold and commissioned in The Netherlands, and further interest expressed from across Europe and around the world.

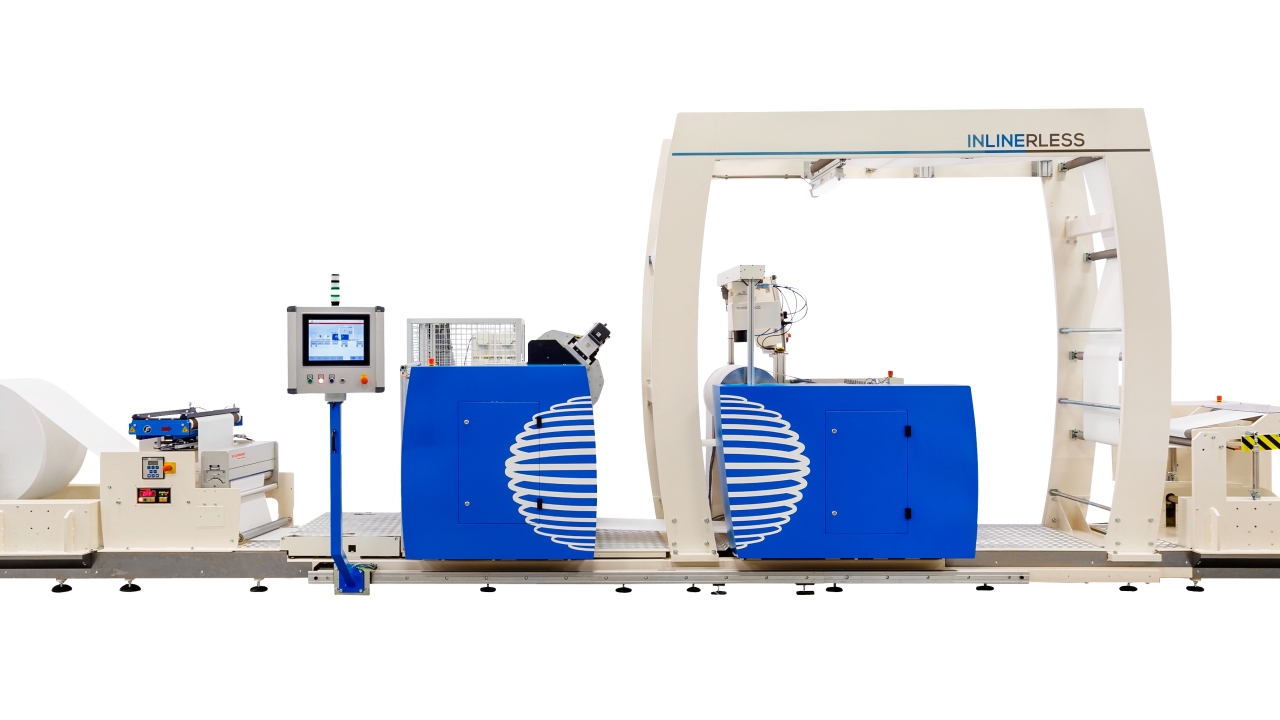

The Inlinerless module is designed to make it possible for label printers to produce high quality linerless labels in an efficient way using existing equipment.

Maan Engineering’s Inlinerless module has been developed to apply a silicone or hotmelt coating to paper or foil in a single process, so allowing the easy production of linerless label material.

The Inlinerless module has been developed as an upgrade to existing printing machinery, but can also be used as a standalone system by fitting unwinder/rewinder positions.

When configured for in-line use, printed material is not reeled but fed through to the Inlinerless module, where it is coated with a top (silicone) and back (hotmelt) coating. After this process, the converted material is fed back over the machine to be reeled at the existing printing line.

Maan Engineering has utilized its expertise in the development of machinery for precise quality coatings to bring the Inlinerless module to market.

Such has been the response to the introduction of the Inlinerless module, Maan Engineering has named Yves Lafontaine as its exclusive sales agent in North America and has hired an international account manager in Europe.

The Inlinerless module will be presented at Labelexpo Europe 2015, taking place September 29 to October 2 in Brussels, Belgium. Directly after Labelexpo Europe 2015 an excursion is being organized for interested foreign parties to see a commissioned Inlinerless module.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.