In search of emerging technologies

Until the 1930s, wet glue was perhaps the only technology for label production and application. In 1936, when Ray Stanton Avery created the self-adhesive label, another process evolved and started to grow so much so that in recent times the usage of self-adhesive or pressure-sensitive labels reached a level of almost 50 percent of all the labels produced.

Screen printing is a very old technology, with evolution and further development of this process into other applications somewhere in the 1960s, when plastic containers started replacing the heavy glass containers in packaging consumer products, screen printing directly on containers became popular. This could not really be classified as a mass usage technique as it lacked the decoration capabilities that were fast becoming the need of increasing consumerism. Initially flatbed letterpress and then flexo rotary printing presses with in-line die-cutting provided a good platform for producing multi-colored labels at faster speeds. Introduction of more decorating processes like varnishing, lamination and foiling on these presses made the screen printing on containers lose ground even though screen printing evolved and grew in other application.

Over the next three decades narrow web label production saw landmark changes. Flexography saw immense technological advancements. Print quality improved tremendously and PSA label markets started to register amazing growth and proliferation. The printing and converting speeds which, in the initial years was 10-15m/min on flatbed letterpress Japanese machines of 5-7in widths had grown initially to 10in, which later increased to 13in, 20in and more. The printing and converting machines have also registered an increase in speed, and the new label presses are running at over 200m/min. Ink technologies have also seen rapid changes, from the thick paste inks in letterpress to liquid inks in flexo printing. Drying techniques also changed drastically. In the initial days, printers would hang a paper web after printing on a clothes line to dry and then manually re-roll the labels. Then came the time when hot air drying was introduced on presses to increase speed. With the introduction of UV inks the speeds shot up tremendously. As production speeds increased, the number of printers also increased, bringing intense competition. The need to reduce wastage and energy became an imperative to stay profitable. New changes and processes started to emerge on presses. The short web path, continuous production, in-line inspection and a host of other changes were taking place in label presses. The introduction of UV LED inks is another step towards conservation of energy. Need for short runs, variable data printing and the speed of creation from computer to print made digital printing to also grow and evolve.

At the beginning of the new millennium, to stay ahead of competition, label printers started to invest in hybrid machines with capabilities to print and convert with multiple technologies. Different printing technologies are now possible on the same equipment. Screen printing re-emerged in label printing machines with rotary screens, where high deposition of color is needed. Gravure printing is also now a part of a label printing press where metallic inks are to be printed. Today presses are available with flexo, offset, gravure, digital and screen printing in-line on the same press along with decorating and finishing like varnishing, lamination, embossing/debossing, die-cutting, waste matrix removal, slitting and sheeting in a single pass. The label presses have further evolved to have multi-substrate printing and converting capabilities. They are now capable of handling films of 12 micron thickness to thick boards. This equipment is now able to produce a wide range of end products like labels, flexible packaging, shrink sleeves, laminated tubes and folding cartons.

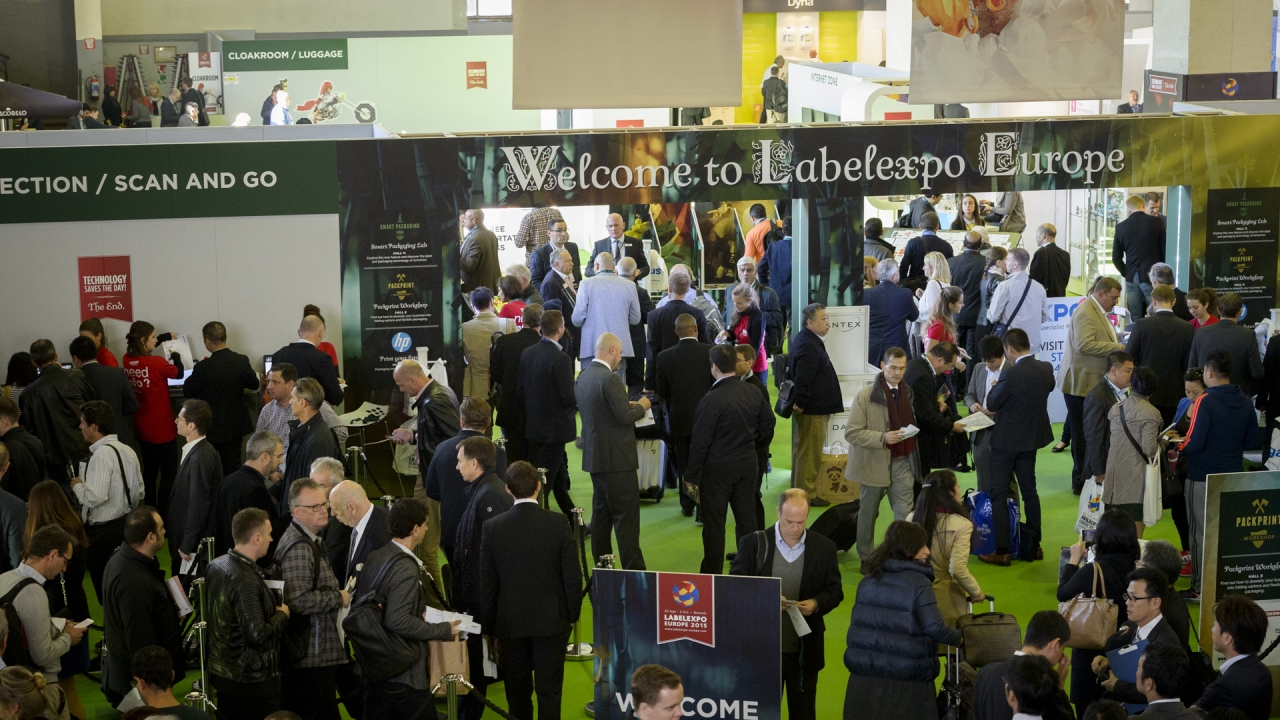

Labelexpo Europe has been the front runner in showcasing the evolving label printing and converting technologies. It remains the must-attend show for label printers spread across the world. Global suppliers of equipment, tooling, consumables, software, other related material and service providers exhibit their products along with new developments made by them at this premium show. This year, 650 exhibitors will showcase their offerings at Labelexpo Europe 2017. At the last showing in 2015, 31,795 visitors came from 158 countries to witness the labels evolution taking place and showcased in seven halls that have now increased to nine halls. Digital label printing and converting that had a miniscule presence some years ago is now spread in dedicated halls with 65 digital presses in operation. The show has grown from strength to more strength over the years.

The story in India is no different, as one the fastest growing economies in the world, the label industry also is growing at a healthy and steady pace. Indian label printers have started to patronize this exhibition in growing numbers that keep swelling in every showing of this premium event. In an effort to assess the mood of the leading label companies in India, I have asked them about their interest in the event or what motivates them to be there and maybe about their intention to buy.

Planning to visit Labelexpo Europe for the first time, Bangalore-based Arvind Shekhar, director of Sai Packaging, says, ‘it will be my first visit and I am looking forward to the opportunity to learn.’ Also planning to visit first time is Himanshu Kapur, director of J K Fine Prints in Mumbai. He is son of past LMAI president Surendra Kapur. Himanshu feels it is necessary to be at the show since no one wants to be left behind in the technology race for achieving perfection. His views are reaffirmed by Uday Lodha, director of Barcom, also in Mumbai. ‘I will attend Labelexpo because I have missed out on the last two occasions and being part of the label fraternity I can’t afford to do that this time around and of course I look forward to connect with friends, colleagues and associates under one roof which is brimming with world class innovation and supreme technological advancements.’

The changing scenario in the global label industry has made many printing companies sit up and study the developments taking place. No other event in today’s time brings together the complete gamut of changes happening in the label industry globally. Mukesh Goel, director at Gopsons Papers of New Delhi, wishes to understand the technological advancements and future direction of this industry. Y H Solanki, managing director at Sicon Packs, expresses that it is the biennial knowledge point for understanding the evolution of labels and the direction it is going in.

The Indian industry is convinced that it is time to make strategic decisions to restructure or plan their moves for leading their companies to new directions and excel. Hyderabad headquartered Pragati Pack has been at the forefront of industry constituents who are consistently investing in emerging technologies. It has not missed a Labelexpo for many years. Though the CEO of Pragati Group and industry stalwart, Narendra Paruchuri, is not attending, his son Hemanth Paruchuri will attend, and says, ‘it is an important show that gives insights into trends in the industry and also showcases the latest technology.’ Jaideep Singh, owner of Zodiac Printers, also from Hyderabad, expresses that the show is a melting pot of all new innovations from across the globe. To be there is necessary to understand and assimilate, which enables us to plan future strategies, he says.

With India attracting the interest of global players in labels and packaging, notable investments have taken place mostly as acquisition of running successful enterprises by companies like Huhtamaki, Skanem, ITW, etc. Amar Chhajed, president of Huhtamaki PPL, says, ‘we will be studying the latest developments in digital printing and finishing as well as new age technologies like EB curing. Sustainable raw material is also an area of special interest to us.’ Hariharan Venkataraman, managing director of Skanem Interlabels Industries Mumbai-India, will attend Labelexpo to catch a glimpse of the frontiers of labeling technology.

Exhibitors are always on the lookout of printers who will take purchase decisions. Raveendran, managing director of Sel-Jegat Printers in Sivakasi, South India, will attend Labelexpo Europe 2017 to finalize a machine investment in the latest technology for the production of special labels, as well as packaging. The company also intends to spend more time looking at digital printing equipment to understand and subsequently invest in the same. Harish Gupta, director of Sai Com Codes, plans to finalize two more lines for its expansion.

A rapidly growing market size and increasing number of label printing companies has brought with it intense competition. Added to this, the print buyers resorting to cost cutting measures like reverse auctions has made converters sit up and consider measures to innovate, create new products, be more efficient and produce cost effectively. Sanjeev Sondhi, director at Zircon Technologies India, will attend Labelexpo Europe 2017 with an intent to explore new technologies to produce to economies of scale and to add such value which can command better price. Sandeep Zaveri, managing director of Total Prints, and LMAI president, will be looking forward to see many innovations and the latest equipment running on the show.

Networking at such events brings about comradeship, amongst global label industry printers and suppliers. It builds bridges of friendship that leave lasting memories for industry members to look forward to and to return to the show in its next edition. Kuldip Goel, Anygraphics managing director, is convinced that Labelexpo is not just an eye opener to the future trends, it also brings the global label fraternity a lot closer. It provides amazing networking opportunities.

Manish Desai of Mudrika Labels, and another past LMAI president, says ‘Labelexpo delivers endless knowledge and networking opportunities with fellow label printers and suppliers.’

Read L&L's comprehensive Labelexpo Europe 2017 preview in issue 4

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.