Legacy and growth at Ekitekken

Since Constanza Calvi took over as CEO in 2023, Argentina-based Ekitekken, a family-run company, has experienced remarkable growth.

It has been a busy 12 months for Argentina-based label converter Etiketten, with the arrival of new flexo and digital presses – from Hontec and HP Indigo, respectively – as well as a move to a new, larger facility in its hometown of Galvéz in Santa Fe province.

The family-run company has maintained an impressive growth trajectory under CEO Constanza Calvi, who stepped into the leadership position from her role as head of administration and HR following the sudden death of her father, Germán, in December 2023 at the age of 59.

As well as its investments in new presses and a bigger plant, Etiketten’s headcount has risen by 30 percent to 52 staff. New finishing equipment will be added soon.

Constanza Calvi has built a youthful leadership team and is preparing the company for its next stage of growth. ‘My challenge is to honor my father’s legacy and lead Etiketten into a new stage of development,’ she says. Foundations Germán Calvi, the fourth generation of graphics industry professionals in his family, founded Etiketten – the German word for label – in Galvéz in Argentina’s Santa Fe province in 2004.

The fledgling company began production in a 50sqm space with a single 4-color flexo press. ‘My father combined technical expertise with a strong focus on service and developing long-term relationships with his clients based on trust, rapid response, and sustained quality,’ says Constanza Calvi.

It was a strategy that proved effective. The company experienced consistent growth, and in 2011, it installed an 8-color Mark Andy flexo press, significantly improving its productivity and the quality of its output. In 2017, Etiketten added Constanza Calvi has been CEO of Etiketten for just under two years digital capabilities with the installation of its first HP Indigo 6800.

My challenge is to

honor my father’s

legacy and lead

Etiketten into a new

stage of development

‘Demand for shorter runs was increasing as supermarkets were increasingly offering multiple SKUs,’ says Constanza Calvi. ‘There used to be only one or two choices of marmalade; now there are five or more. The move into digital printing was key. From that point onwards, the expansion strategy combined technology, operational efficiency and customer proximity.’

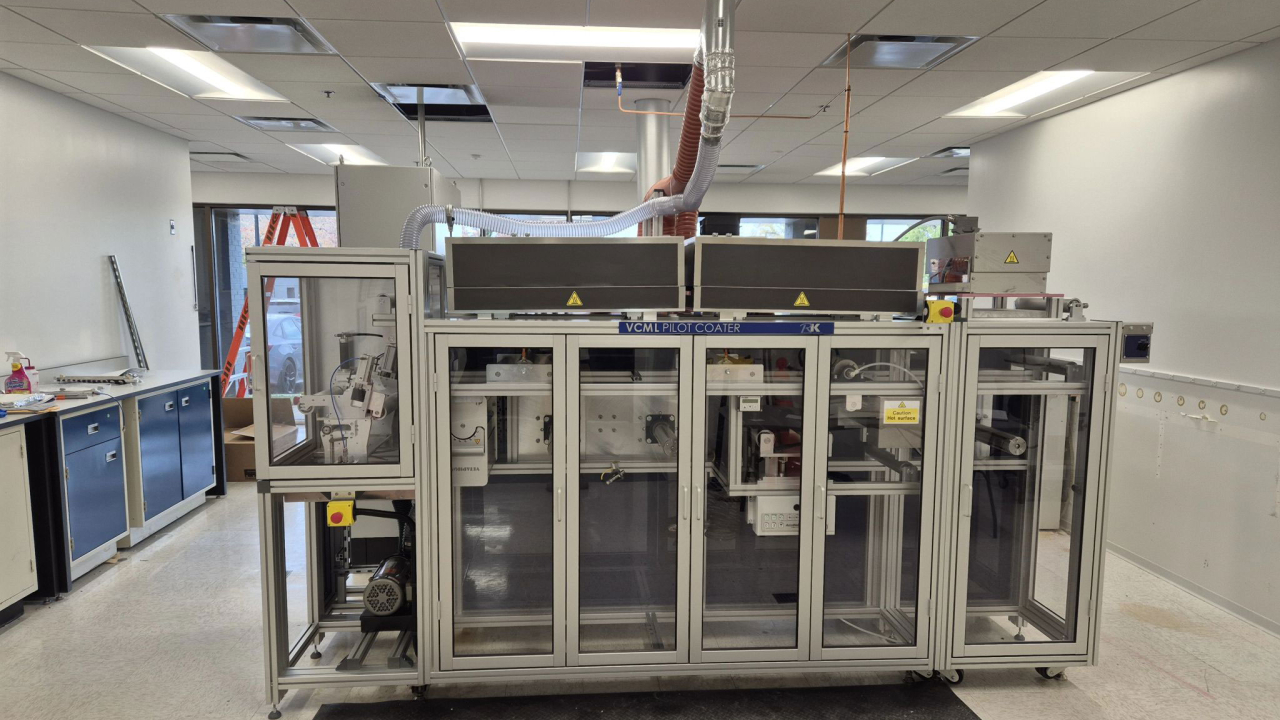

Today, Etiketten’s new industrial plant has more than 1,600sqm of covered space, a warehouse with stock for three months of production and modern 350sqm offices. The 7,200sqm facility is located in an industrial zone with space for expansion. It now runs two Mark Andy flexo presses – a 2200 and a Scout – both with eight printing units, in-line die-cutting, inspection camera and reverse printbar. Both have a web width of up to 250mm.

The company has three 7-color HP Indigo 6K presses with a capacity of up to 330mm

wide, providing versatility and customized production of high quality and complexity.

Finishing and die-cutting are handled by A B Graphic DigiLite and Brotech SDF 330 machines, supported by A B Graphic Omega SRI3 rewinders with an integrated inspection system and automated control.

Late last year, Etiketten installed a new Hontec FlexiCon 460-8C press, an 8-color machine that allows printing on a wide range of substrates. With a maximum

web width of 450mm, it includes a water-cooling system, UV LED curing,reverse printbar and pre-registration.

Germán Calvi had seen the Hontec press at Labelexpo Europe in Brussels in 2023 and had ‘fallen in love with it because of its production quality and its flexibility’, according to Constanza Calvi.

The company already had a relationship with Hontec’s local distributor in Argentina, which facilitated communication with the Chinese manufacturer. ‘We’ve had good

communication with Hontec,’ reports Constanza Calvi. ‘It takes time to switch between machines and to get used to a new one, but the installation has been a success and we are very happy with the press.’

Constanza Calvi and some of her team traveled to Barcelona in September to attend Labelexpo Europe 2025, with the aim of choosing a finishing system to help

handle the additional output brought by Etiketten’s recent press installations.

Color quality control is performed using high-precision spectrophotometers, and

the entire production process is integrated under a custom-developed management system.

The company currently processes approximately 500,000sqm per month. From its sales office in Vicente López, Buenos

Aires, a group of technical and commercial advisors ,serves clients

throughout the country.

We have a triple impact approach: economic, social and environmental.

It’s not just an idea, but a daily practice

Room for growth

Etiketten is 100 percent dedicated to label production, but Constanza Calvi says that the machinery at the company’s disposal would facilitate a move into different types of production, such as flexible packaging, in the future. ‘For the time being, we still have room to grow in the label sector,’ she says.

Etiketten supplies to a various industrial sectors, from local start-ups to large multinational companies. It serves renowned brands in the food, beverage, cosmetics, laboratory, dietary supplement, cleaning, paint and other premium product sectors.

Its clients include Minerva Foods, Arcor, Saputo, Marfrig, Alfa Parf Milano, Schoott and Abbott Laboratories, among others. Another important sector for Etiketten is labels for refrigerated food: dairy products such as milk and cheeses, as well as meat

products. The company’s local province of Santa Fe has a strong farming industry.

Etiketten also serves the automotive sector, with labels for products such as oils and lubricants. Constanza Calvi cites air fresheners as a growing market, with one of the converter’s clients in this segment seeing particularly strong growth. Etiketten’s production is all currently for the domestic market, though some multinational clients export their products.

‘We don’t have any clients outside Argentina, but that could change in the

future,’ says Constanza Calvi. Argentine president Javier Milei has lifted the myriad currency controls and import and export restrictions put in place by the

previous government, which had hampered local converters’ ability not only to import materials and export finished labels, but even to pay foreign suppliers.

‘It has become easier to import materials since the restrictions have eased,’ says Constanza Calvi. ‘Things don’t get held up in customs like they used to. It’s easier to pay suppliers abroad.

Opening up the export market is also a positive development. However, it also brings great challenges for businesses.’

Leadership

When Germán Calvi was in charge, Constanza Calvi, as head of administration and HR, and two production shift leaders reported to him. After his passing, staff and clients alike advocated for her to take over as the face of the family. Constanza Calvi united the

heads of different departments to be company’s leadership group.

‘I wanted to have a wide range of skills leading the company,’ she says. The leadership group comprises Antonela Gario, administration manager; Sebastián Ferrero, head of systems and IT; Daniela Morales, quality and purchasing manager; Lucas Oviedo,

operations manager; and Manuel Hormaiztegui, sales manager.

Etiketten’s leadership team has sought external advice to help it continue its growth trajectory. Industry expert Luis María García, who co-founded and ran Argentine converter Multilabel for 22 years, overseeing expansion into Brazil and Mexico, is providing support and advice as an independent consultant.

‘Luis María has been a great support to us and has offered a lot

of help,’ says Constanza Calvi. ‘We are very grateful for his advice

and input.’

Etiketten is certified under ISO 9001:2015 and is in the process of

becoming a B Corporation, a company that has voluntarily met the

highest standards for social and environmental performance. ‘We

are aware of the importance of companies having a positive social

and environmental impact,’ says Constanza Calvi.

Sustainability policies include energy efficiency, responsible

waste management, carbon footprint measurement and continuous

improvement in production processes. ‘The new plant was designed

with these criteria in mind from its inception,’ she notes.

‘We have a triple impact approach: economic, social and

environmental,’ she says. ‘It’s not just an idea, but a daily practice.

The company actively promotes a healthy work environment,

implementing internal surveys to measure the work environment,

conducting performance evaluations and encouraging the active

participation of our employees, prioritizing equal opportunities,

ongoing training and teamwork.’

Germán Calvi’s entrepreneurial spirit remains alive in

Etiketten’s culture.

‘My father’s legacy transcends the technical and is reflected in

every decision, process and relationship,’ says Constanza Calvi. ‘We

combine that legacy with a modern, professional vision oriented

toward sustainable growth. We believe that supporting our clients

in their development also means growing with them.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.